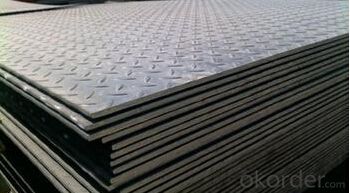

Hot Rolled checkered plate from China, A36, ST37-2

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product: | Hot Rolled Steel Coils/Sheets |

Material: | Q195,Q235,A36,SS400,S235JR,Q345,ST37-2, CCSB etc |

Standard : | JIS G3002 GB/T251B |

Technique: | hot rolled |

Thickness | 1.2mm to 200mm |

Tolerance of thickness: | :+/-0.03mm |

Width: | 750mm-2000mm |

Tolerance of width: | :+/-5.00mm (aiming to +/-2.00mm) |

Normal width: | 914mm, 1000mm, 1200mm, 1219mm, 1250mm,1500mm |

Length: | According to requirement |

Coil ID: | 508mm-610mm |

Coil Weight: | 10-25 Metric Tons |

Surface: | Black, Chromate, fingerprint resistant treatment, slight oiled or non-oiled, dry |

Port of Loading: | Tianjin/Shanghai port |

Packaging Details: | Standard export packing or according to the clients required |

Delivery Time | Within 30 days after received 30% deposit or workable L/C |

Payment Terms: | L/C,T/T |

- Q: why do you need to heat steel when hardening, molecules etc etc

- Metalurgy is a fascinating science which has been used to mark the ages of civilization: the Bronze Age, the Iron Age, etc. Ancient sword makers heated steel until the polished surface showed a straw color (which we now know to be about 550°F, and due to surface oxides) and then plunged the blade into a tank of water. The blade was quickly removed, repolished, and observed closely for heat transfer from the core returning the surface to straw color. If so, it was quenched again. This technique left the surface hard without making the blade brittle. Today the steel crystal lattice is known to be either face centered cubic (iron atoms at the corners of a cube and iron atoms centered in the faces of the cube) or body centered cubic ( iron atoms at the corners of the cube and an iron atom at the geometric center of the cube). Most experienced machinists can estimate the temperature of steel from the color of its surface oxides.

- Q: I need to identify a metal. It is rusty so I suspect it is either iron or steel. Since they both have similar densities and are magnetic, how do I tell the difference betweeen steel and iron?

- Iron and Steel Manufacture, technology related to the production of iron and its alloys, particularly those containing a small percentage of carbon. The differences between the various types of iron and steel are sometimes confusing because of the nomenclature used. Steel in general is an alloy of iron and carbon, often with an admixture of other elements. Some alloys that are commercially called irons contain more carbon than commercial steels. Open-hearth iron and wrought iron contain only a few hundredths of 1 percent of carbon. Steels of various types contain from 0.04 percent to 2.25 percent of carbon. Cast iron, malleable cast iron, and pig iron contain amounts of carbon varying from 2 to 4 percent. A special form of malleable iron, containing virtually no carbon, is known as white-heart malleable iron. A special group of iron alloys, known as ferroalloys, is used in the manufacture of iron and steel alloys; they contain from 20 to 80 percent of an alloying element, such as manganese, silicon, or chromium.

- Q: How are steel coils uncoiled?

- Steel coils are typically uncoiled using a machine called a decoiler or uncoiler, which gradually unwinds the coil by feeding it through a set of rollers. The rollers apply tension to the coil, allowing it to unwind smoothly and evenly. The speed and direction of the uncoiling process can be controlled to match the specific requirements of the application.

- Q: Can solution annealing be done on carbon and low alloy steels. please give an explanatory answer.

- No. Carbon steel has two different crystal structures, FCC and BCC , depending on the temperature. when you heat steel up and then quench it, it locks the crystal structure into the BCC form. this makes it hard. whereas precipitation hardened austentic stainlesses remain BCC regardless of the temp, so the hardness change is not a function of thermally induced strain. you can anneal carbon steel but the thermal profile is closer to the precipitation profile of PH stainlesses than it is to the Solution annealing profile.

- Q: how much pressure can steel withstand? and how much pressure can concrete withstand? per m3 or cm3? thanks

- Your question is not specific,there are many types of Concrete according to ratio and many types of steel but if want general answer,Concrete is good for compression and for 1:2:4 Cement-Sand-Gravel Ratio up to 4000 psi but very weak in tension where as tor steel is good for tension and is about 70000-80000 psi .

- Q: If you keep it dry and clean, what steel will last the longest over the years with continued use and sharpening?

- Most okorder /

- Q: What is the standard thickness of steel coils?

- The specific application and industry requirements dictate the standard thickness of steel coils, which can vary. Generally, steel coils are obtainable in thicknesses ranging from 0.5mm to 10mm. Various factors, including intended use, structural requirements, and manufacturing processes, influence the desired thickness of a steel coil. Heavier applications that necessitate increased strength and durability typically employ thicker coils. Conversely, thinner coils are suitable for lighter applications where flexibility and weight reduction are crucial. To determine the appropriate thickness for steel coils in a particular application, it is essential to consult industry standards and specific project requirements.

- Q: Does steel have a valence number and if so, what is it?

- Steel is a mixture, so it doesn't have any valence number. On the other hand, all of the components of the steel mixture are in their elemental forms, so all the various valences are zero.

- Q: How do steel coil manufacturers minimize waste and maximize efficiency?

- Steel coil manufacturers minimize waste and maximize efficiency by implementing various strategies such as optimizing production processes, recycling and reusing scrap materials, adopting advanced technologies for energy conservation, and implementing lean manufacturing principles to eliminate unnecessary steps and reduce downtime. They also focus on continuous improvement, employee training, and regular maintenance of equipment to ensure smooth operations and minimize waste generation.

- Q: How are steel coils used in the production of appliances?

- Steel coils are used in the production of appliances as a primary material for constructing the various components, such as the outer shells, frames, and internal structures. The coils are processed and shaped into specific sizes and forms to meet the requirements of different appliances. Additionally, steel coils provide strength, durability, and a sleek appearance to the finished appliances.

Send your message to us

Hot Rolled checkered plate from China, A36, ST37-2

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords