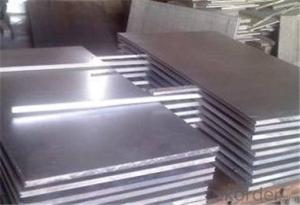

Hot Rolled Steel Plates A36 for Sale in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 59 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of steel sheets:

A36/A516 Gr.60/70 hot rolled oil tank/carbon boiler steel plate/sheet

1.Width:1500--4020mm

2.Length:3000-27000mm

Festures of steel sheets:

Steel plates are widly used as boiler plate, container plate, flange plate and ship plate,

and also widly used in building construction. The size of steel plate can be made according

to clients requirements.

Specifications of steel sheets:

1) Cold rolling

The advantages of cold rolling are good dimensional accuracy ,surface quality ,low surface roughness ,high mechanical properties.The steel surface of the coldrolled (forging) state delivery has oxide skin coverage and there is a great internal stress, so likely to suffer corrosion or rust,.Therefore ,its packaging and storage have relatively strict standards

2) Hot rolling

Hot rolling (forging) steel plate’s termination of a temperature is 800900 degrees Celsius, then generally natural air cooling.Hotrolled steel state because of the surface is covered with a layer of oxide scale,so having some corrosion resistance, less stringent storage and transport requirements, unlike steel cold-rolled state delivery.

Images of steel sheets:

FAQ:

1. What is your package?

Packing situation: standard seaworthy packing or as customer required.

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: Why did Conany ask people to touch the copper plate to see if there was potassium cyanate in his hand?

- Because potassium cyanate and copper chemical reaction, there is a phenomenon to detect whether there is potassium cyanate.

- Q: Offset paper and copper paper feel different

- The paper is smooth and looks bright,Uncoated paper is relatively dull, it is easy to distinguish

- Q: HiI am about to purchase a laptop and i am wondering about solar energyis there a device where i can leave the panel outside in the day that charges a battery to run a 21.5‘‘ tv, wii, and apple macbook and take the panel in at night and where can i find onethanksp.s.an insturional tutorial to bulid one work work tomy price range is $100 $200

- Yes, there are many types of solar chargers on the market. Research on the web by Googling Solar Chargers. That should start you going. P.S. I hope you like reading essays. Agua has written quite a voluminous one!

- Q: What is a carved copper plate?

- Copperplate engraving is engraving directly on copper plates with a carving machine. We use copper engraving machines to carve copper plates. With the carving procedure.

- Q: A flat copper sheet has a hole with area 0.260m^2 at room temperature (25?C). If it‘s heated to 590 ?C, what‘s the hole‘s new area?i think you somehow incorporate the area of a circle, but i am not sure how/then i dunno. lol! en explanation would be great

- Home depot, Lowe, Ebay, Internet vendors or just look around your garage; there may be one little piece laying some where and large enough to make the gasket Good luck!

- Q: This lab was about aluminum reacting with copper (II) chloride. On day one of the lab, we allowed aluminum to react with copper (II) chloride in a beaker filled with water. On day two, we removed the chunks of wet copper (the product) from the beaker and put them on a sheet of filter paper. Finally, on day three, we measured the mass of the dry copper. It was determined that aluminum was the excess reagent and copper (II) chloride was the limiting reagent. There are a few post lab questions that I need help with. Here is a chemical equation to help you: 2Al+3CuCl2 -gt; 2AlCl3+3Cu Which gas was produced in this lab (in Day 1)? State evidence of a gas being produced? Why did the blue color of the solution disappear? (Day 2) Describe the appearance of the product. (Day 2 before filtering) Why did the product have that particular appearance? Thanks for the help!

- Hi Evy, 2 Al(s) + 3 Cu(2+) + 6 Cl(-) 3 Cu(s) + 2 Al(3+) + 6 Cl(-) these are the ions Cu(2 +) that give the blue color to the solution . . . ! All Cu(2 +) ions reacted because Al is in excess . . . that is why the blue color disappears . . .

- Q: 1)For proper installation, can a Thermocouple be installed and connected with copper wire?Explain your answer2) Thermocouple measuring devices need to compensate for ambient temperature because:A) mv tables are based on zero deg C and the measurement junction may changeB) mv tables are based on zero deg C and the reference junction may change C) mv tables are based on ambient temp and the measurement junction may changeD) mv tables are based on ambient temp and the reference junction may change Thanks alot and can someone only with knowledge of instrumentation answer these questions.

- I've seen copper wire used; compensation is usualy prformed at the meters location, so it works out; and too the wire is in the same enviroment as the couple. You could look the second one up on a data-sheet; but I'd say C is correct.

- Q: I have never done it before but would like to try my hands on that just as a hobby. where can i find the materials for that? I stay in sacramento, California. Is it necessary to take any classes to start off or csn i just try it by myself home? Plz guide me

- as far as I know for embossing you will need a metal stamp to press into the metal. And that pretty much limits what you can do. I assume you want to do repousse (see link below) you would slowly work your design into the metal. You would need a bowl with pitch, the size depending on the size of work you want to do, bits of copper sheet, a plumbers torch and a couple of chasing tools (which you can make yourself out of toolsteel if you know how to harden and temper the steel). You anneal the sheet of copper, fix it on the pitch and start working your design in the soft copper. Once it's work hardened you anneal again, but then you work from the other side of the sheet of copper. You repeat the process until you are happy. If you just want to do repousse and have some experience with metal working I don't think you need a class, but it would be useful if you could do silver solderinging and other metal working techniques. Usually those things are taught in jewelry classes, so you could check if there are any offered in your area which include those techniques.

Send your message to us

Hot Rolled Steel Plates A36 for Sale in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 59 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords