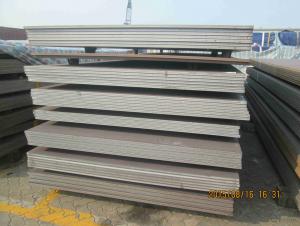

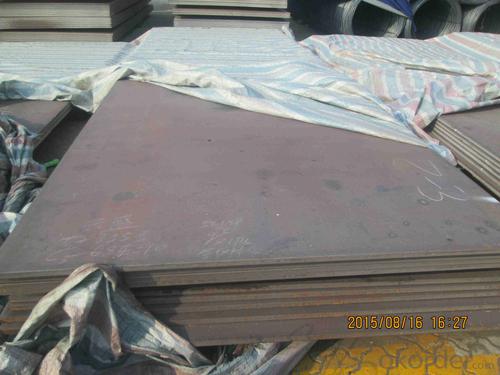

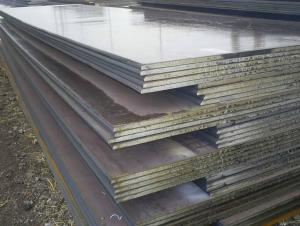

Hot Rolled Carbon Steel Plates in High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Carbon Steel Plates in High Quality at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Carbon Steel Plates in High Quality are ideal for structural applications and are widely used in construction,machinery manufacturing, container manufacturing, shipbuilding, bridge construction. Can also be used to manufacture a variety of containers, the furnace shell, furnace plate, bridge and vehicle static steel plate, low alloy steel plate,shipbuilding plate, boiler plate, pressure vessel plate, pattern plate, tractor parts, automobile frame steel plate and welding components.

Product Advantages:

OKorder's Hot Rolled Carbon Steel Plates in High Quality are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Standard:AISI, ASTM, DIN, GB, JIS

Grade:Q195,Q235,SS400,A36,Q345B

Thickness:1.5mm-200mm

Place of Origin:Tianjin, China (Mainland)

Model Number:1.5mm-200mm steel plate

Type:Steel Plate

Technique:Hot Rolled

Application:Ship Plate

Special Use:High-strength Steel Plate

Width:600mm-3200mm

Length:any length

MOQ:500 tons

Steel Plate

1.Dimension:8-100

2.Length:1000-12000

3.Grade:Q235,SS400,A36,Q345

4.Large stock, low price, high quality

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Images:

- Q: Are the steel sheets suitable for architectural cladding?

- Yes, steel sheets are suitable for architectural cladding. Steel is a strong and durable material that provides excellent protection against weather elements and other external factors. It can be easily shaped and fabricated into various designs, making it highly versatile for architectural applications. Steel cladding also offers a modern and sleek aesthetic, allowing for flexibility in creating visually appealing building façades. Additionally, steel sheets can be coated or painted to enhance their corrosion resistance and further customize their appearance. Overall, steel sheets are a popular choice for architectural cladding due to their strength, durability, versatility, and aesthetic appeal.

- Q: What is called steel plate sanding process?

- Sand blasting can remove the oxide surface and floating rust on the surface of steel plate. It is a good process before anticorrosion painting. Sandblasting of other components may be more useful for pre coating treatment.

- Q: What are the common sizes and thicknesses of steel sheets?

- The common sizes of steel sheets typically range from 4 feet by 8 feet (1.2 meters by 2.4 meters) to 5 feet by 10 feet (1.5 meters by 3 meters). As for thicknesses, they can vary from 16 gauge (0.0598 inches or 1.52 millimeters) to 10 gauge (0.1345 inches or 3.42 millimeters). However, it's important to note that there are numerous other sizes and thicknesses available depending on specific applications and requirements.

- Q: Are steel sheets suitable for architectural projects?

- Architectural projects can indeed utilize steel sheets as they offer numerous advantages. Steel, being a versatile and durable material, is highly suitable for such applications. First and foremost, steel sheets possess immense strength, enabling them to bear heavy loads. This makes them perfect for structural elements in buildings. The high strength-to-weight ratio of steel sheets allows for the creation of large and open spaces without the need for excessive supporting columns or walls. Consequently, steel sheets are ideal for constructing expansive interior spaces like atriums, stadiums, and other architectural projects. Furthermore, steel sheets can be easily shaped and formed into various architectural designs. They can be curved, rolled, or bent to fashion unique and intricate structures. Steel's malleability empowers architects and designers to challenge conventional building designs and create visually stunning and innovative structures. Moreover, steel sheets exhibit resistance to corrosion, weathering, and fire, making them suitable for outdoor applications and ensuring the longevity of architectural projects. The durability of steel also translates into minimal maintenance requirements throughout its lifespan, resulting in long-term cost savings. In addition, steel sheets offer a wide range of finishes, textures, and colors, facilitating customization and aesthetic versatility in architectural projects. Whether aiming for a sleek and modern design or a rustic and industrial look, steel sheets can be tailored to meet the desired aesthetic requirements of the project. To sum up, steel sheets are an excellent choice for architectural projects owing to their strength, versatility, durability, and aesthetic appeal. Their ability to withstand heavy loads, be shaped into various designs, resist corrosion and fire, and offer customization options make them a favored material for architects and designers to turn their visions into reality.

- Q: The difference and usage of color steel sandwich panel and color profiled steel sheet

- The color impression plate is a component of the sandwich panel, that is, two profiled steel plates. Usually used as site block, warehouse panel

- Q: Are the steel sheets available in different thickness tolerances?

- Certainly, there are various thickness tolerances for steel sheets that are readily available. Steel producers create sheets with diverse thicknesses to accommodate different purposes and demands. These tolerances are determined by established standards within the industry and can differ based on the steel type and intended application. In construction, for instance, tighter tolerances might be mandatory to guarantee the structural soundness, while in manufacturing sectors like automotive or aerospace, precise tolerances may be indispensable to meet design requirements. Through offering steel sheets in varying thickness tolerances, manufacturers allow customers to select the most fitting product for their individual requirements.

- Q: Can steel sheets be used for electrical switchgear?

- Yes, steel sheets can be used for electrical switchgear. Steel is a common material choice for switchgear enclosures due to its durability, strength, and ability to provide protection from environmental factors such as moisture, dust, and temperature fluctuations. Steel sheets are commonly used in the construction of switchgear cabinets and enclosures to provide a robust and secure housing for electrical components. The steel sheets used for switchgear are typically coated or painted to provide additional protection against corrosion. Additionally, steel is a good conductor of heat, which helps dissipate any heat generated by the electrical components within the switchgear. Overall, steel sheets are a suitable material for electrical switchgear enclosures due to their mechanical properties, protective capabilities, and thermal conductivity.

- Q: What is the difference between a galvanized and painted steel sheet?

- A galvanized steel sheet is coated with a layer of zinc, which provides protection against corrosion. On the other hand, a painted steel sheet is coated with a layer of paint, which provides aesthetic appeal and protection against weathering.

- Q: Are steel sheets susceptible to rusting?

- Yes, steel sheets are susceptible to rusting. Steel is primarily made up of iron, which is a metal that naturally reacts with oxygen in the presence of moisture to form iron oxide, also known as rust. This means that if steel sheets are exposed to water or moisture, they can begin to rust over time. However, there are methods to prevent or slow down the rusting process, such as applying protective coatings or using stainless steel, which contains elements like chromium that provide additional resistance to corrosion.

- Q: Can steel sheets be used for staircase railings?

- Yes, steel sheets can be used for staircase railings. Steel is a durable and strong material that is commonly used in construction and engineering applications. Steel sheets can be fabricated into various shapes and designs to create stylish and modern staircase railings. They can be easily customized to suit different architectural styles and preferences. Additionally, steel railings are known for their longevity and low maintenance requirements, making them a popular choice for staircase installations.

Send your message to us

Hot Rolled Carbon Steel Plates in High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords