Hot Rolled Carbon Steel Plate,Carbon Steel Sheet LRB CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI, ASTM, GB, JIS | Grade: | Q195,Q235,Q345,A36,C45 | Thickness: | 1.0-30MM |

| Model Number: | Q235,Q195,Q345 | ||||

| Type: | Steel Plate | Technique: | Hot Rolled | Surface Treatment: | Coated |

| Application: | Ship Plate | Special Use: | Silicon Steel | Width: | 30-2000mm |

| Length: | as your requirement | standard: | hot rolled | Surface: | Anti-rust oil |

Packaging & Delivery

| Packaging Details: | seaworthy packages or as customers' require |

| Delivery Detail: | within 15 days after the advance payment |

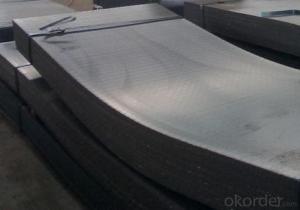

Hot rolled steel plate

1 carbon steel plate 3mm thick General information

| Product name | Type | Specification | Implementation of GB | ||

| thick | wide | long | |||

| Carbon structural steel | Q195,Q215, Q235A,Q235B, Q235C,Q255, Q275 | 4-120 | 1500-4500 | 6000-12000 | GB/T700-2006 |

| Low-alloy structural steel | Q295,Q345A, Q345B,Q2345C | 4-120 | 1500-4500 | 6000-12000 | BG/T1591-1994 |

| Quality carbon structural stee | 30-50 | 4-120 | 1500-4500 | 6000-12000 | BG/T699-1999 |

| Ship steel | CCSA,CCSB | 4-120 | 1500-4500 | 6000-12000 | materials and welding condition |

| CCSAH32,CCSAH36 CCSDH32,CCSDH36 | 4-120 | 1500-4500 | 6000-12000 | materials and welding condition or GB 712-2000 | |

| Boiler steel | 20g,22Mng, 16Mng,19Mng | 4-120 | 1500-4500 | 6000-12000 | GB 713-1997 |

| Pressure vessel steel | 1622Mng,20R, 15MnVR,15MnVNR | 4-120 | 1500-2700 | 6000-12000 | GB 6654-1996 |

| European standard plate

| S235JR,S235J0, S275JR,S275J0, S275JR2,S355JR, S355J0,S355J2 | 4-120 | 1500-4500 | 6000-12000 | EN 10025 |

| Japanese standard plate | SS400,SS400-B | 4-120 | 1500-4500 | 6000-12000 | JIS G3101-2004 |

2 carbon steel plate 3mm thick detail specification

Material:

A283Gr.D/A573Gr.65,A516Gr65,A516Gr70,A284Gr.D

SS400,SS300,CCSB A36,A32,LRA32,LRB,Q235

Q195,Q235,Q345,SS400,ASTM A36,E235B

Thickness: 4mm-120mm

width: 1500mm-4500mm

Length:2-10m ,accordingly

Thickness | 4-120mm |

Width | 1500-4500mm or as custom's request |

Length | 2-12m,as your requirment |

Technique | Cold rolled or hot rolled |

Surface treatment | Bare, galvanized coated or as customer's requirements. |

Standard | ASTM,EN,GB,JIS,GB |

Material | A283Gr.D/A573Gr.65,A516Gr65,A516Gr70,A284Gr.D SS400,SS300,CCSB A36,A32,LRA32,LRB,Q235 Q195,Q235,Q345,SS400,ASTM A36,E235B |

Terms of Payment | L/C or T/T |

Chemical composition | C≤0.004%;Si≤0.030%; Mn ≤0.17%;P≤0.012%; S≤0.010%; Fe balance |

Delivery Detail | within 30days once receive deposite or confirm L/C |

Packing | Standard export packing,or as requirement |

3 carbon steel plate 3mm thick application:

construction,machinery manufacturing, container manufacturing, shipbuilding, bridge construction. Can also be used to manufacture a variety of containers, the furnace shell, furnace plate, bridge and vehicle static steel plate, low alloy steel plate,shipbuilding plate, boiler plate, pressure vessel plate, pattern plate, tractor parts, automobile frame steel plate and welding components

- Q: Can steel sheets be used in the manufacturing of furniture?

- Yes, steel sheets can be used in the manufacturing of furniture. Steel is a durable and versatile material that can be shaped and formed into various furniture components like frames, legs, and surfaces. Additionally, steel sheets provide strength and stability to furniture pieces, making them suitable for both indoor and outdoor use.

- Q: How are steel sheets coated for corrosion resistance?

- Galvanization is a common technique for protecting steel sheets from corrosion. It involves adding a layer of zinc to the surface of the steel sheet. There are two ways to do this: hot-dip galvanization and electro-galvanization. During hot-dip galvanization, the steel sheet is dipped into a bath of molten zinc. The zinc adheres to the steel through a metallurgical reaction. This creates a protective barrier that prevents moisture and oxygen from reaching the steel, thus stopping corrosion. Electro-galvanization, on the other hand, uses an electric current. The steel sheet is placed in a zinc electrolyte solution, and the electric current causes the zinc ions to be attracted to the steel surface. This forms a thin layer of zinc coating. This method is usually used for thinner steel sheets or when a precise coating thickness is needed. Both hot-dip galvanization and electro-galvanization effectively protect steel sheets from corrosion. The zinc coating acts as a sacrificial layer, meaning it corrodes before the steel underneath. This prolongs the lifespan of the steel sheet and prevents rust. Additionally, the zinc coating can also provide a decorative finish, making it suitable for practical and aesthetic purposes. In conclusion, galvanization is a widely used and effective method for enhancing the corrosion resistance and durability of steel sheets.

- Q: What's the difference between the three kinds of pickling plate, cold rolled plate and hot rolled plate?

- Cold rolled plate: that is, the cold rolled base plate (that is, hot rolled plate) rolled in the normal temperature condition. Because of the great cold rolling stress, it usually goes through the annealing process

- Q: What are the different sheet metal forming techniques for steel sheets?

- There are several sheet metal forming techniques for steel sheets, including bending, deep drawing, punching, shearing, and roll forming.

- Q: How do steel sheets compare to glass sheets?

- Steel sheets and glass sheets have distinct characteristics that make them suitable for different applications. Firstly, steel sheets are known for their strength and durability. They can withstand heavy loads and are highly resistant to impact and damage. This makes them ideal for construction purposes, such as in the manufacturing of buildings, bridges, and machinery. Additionally, steel sheets offer excellent protection against fire and extreme weather conditions. On the other hand, glass sheets are valued for their transparency and aesthetic appeal. They allow natural light to pass through, creating a bright and open atmosphere. Glass sheets are commonly used in windows, doors, and architectural structures to provide visibility and enhance the visual appeal of a space. Furthermore, glass sheets offer excellent thermal insulation properties, which can help reduce energy consumption in buildings. In terms of maintenance, steel sheets require minimal upkeep as they are resistant to corrosion and do not require regular cleaning. However, they may require painting or protective coatings to prevent rusting. On the contrary, glass sheets may need regular cleaning to maintain their transparency and appearance. They are also more prone to scratching and breakage compared to steel sheets. Lastly, cost is an important factor to consider. Steel sheets typically have a lower initial cost compared to glass sheets. However, the overall cost may vary depending on factors such as size, thickness, and quality. Additionally, the cost of installation and maintenance should also be taken into account. In conclusion, steel sheets and glass sheets have their own unique characteristics and properties. The choice between the two would depend on the specific requirements of the project, including strength, transparency, aesthetics, maintenance, and cost considerations.

- Q: Are steel sheets resistant to graffiti?

- Yes, steel sheets are generally resistant to graffiti due to their smooth and non-porous surface, which makes it difficult for spray paint or other graffiti materials to adhere to the surface. Additionally, steel sheets are often coated with protective layers such as paint or anti-graffiti coatings, which further enhance their resistance to graffiti.

- Q: Can steel sheets be used in food processing or medical industries?

- Yes, steel sheets can be used in food processing and medical industries. Stainless steel sheets, in particular, are commonly used due to their excellent resistance to corrosion, hygiene properties, and durability. They meet the strict requirements of these industries, ensuring safe and sanitary processing environments.

- Q: What is the typical coefficient of thermal expansion of a steel sheet?

- The typical coefficient of thermal expansion of a steel sheet is around 10.8 x 10^-6 per degree Celsius.

- Q: Are steel sheets suitable for flooring applications?

- Yes, steel sheets are suitable for flooring applications. Steel sheets are known for their durability, strength, and resistance to wear and tear. They can provide a stable and long-lasting flooring option in various settings, including industrial, commercial, and even residential spaces. Additionally, steel sheets can be easily customized to meet specific design requirements, making them versatile for flooring applications.

- Q: How do steel sheets perform in terms of thermal expansion?

- Steel sheets have a relatively low coefficient of thermal expansion, meaning they expand and contract minimally when subjected to changes in temperature. This makes them excellent for applications where thermal stability is crucial, as they can maintain their shape and dimensions without warping or distorting.

Send your message to us

Hot Rolled Carbon Steel Plate,Carbon Steel Sheet LRB CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords