Aluminum Hot Rolled Circle Sheet AA1100 H14

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Hot Rolled Aluminum Circle Sheet AA1100 H14 Description

• Product: Aluminim Circle

• Application: It is used in cookware, engineering, lighting purpose, fried pans, non-sticky pans, cooking pots, kettles, hard anodize cook wire, pressure cooker and house hold utensils, reflector of the light, etc

• Advantage: Deep drawing and hard anodizing quality Aluminum Circle Sheet can be supplied. Our Aluminum Circle is RoHS and REACH compliance and uses well-protected packing. Our circles are excellent material for producing cookware, utensil, pots, pans and kettles.

2.Main Features of the Hot Rolled Aluminum Circle Sheet AA1100 H14

• High manufacturing accuracy

• Smooth surface

• No waves

• High strength of extension and yield

• Well packaged

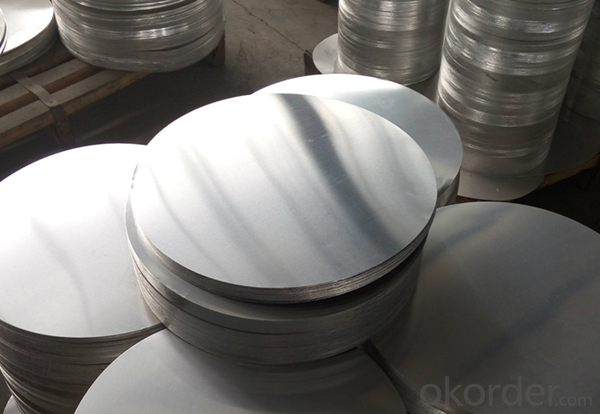

3.Hot Rolled Aluminum Circle Sheet AA1100 H14 Images

4.Hot Rolled Aluminum Circle Sheet AA1100 H14 Specification

Alloy | AA1050,AA1060,AA1100 AA3003etc. |

Temper | O,H14 |

Thickness | 0.5MM-4MM |

Diagonal | 100-1200MM |

Standard | GB/T 3880-2006 |

5.FAQ of Hot Rolled Aluminum Circle Sheet AA1100 H14

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

5.Quality contral:

1. Professional Quality Control Team

v Inspecting ingot before melting

v Inspecting aluminium coil stock before cold rolling

v Inspecting finished goods before package

v Inspecting package, loading before shipment

2. Guaranteed by ISO 9001:2008 (SGS)

3. Guaranteed by FDA, EN 602, TPCH etc

- Q: This question asks for a comparison of the pros and cons of using aluminum sheets as a roofing material.

- <p>Advantages of using aluminum sheets for roofing include their lightweight nature, which reduces structural load; corrosion resistance, making them suitable for coastal areas; and low maintenance requirements. They are also energy-efficient, reflecting heat and reducing cooling costs. Disadvantages include the potential for dents and damage from hail or heavy impacts, and they can be more expensive than some other roofing materials. Additionally, aluminum can be noisy during rain, and it may require more frequent replacement compared to some other materials due to its lighter gauge.</p>

- Q: Explain the connection between aluminum and its interaction with electromagnetic radiation.

- <p>Aluminum has a unique relationship with electromagnetic radiation due to its reflective and conductive properties. It is a good reflector of visible light and infrared radiation, which is why it is used in applications such as mirrors and reflective coatings on windows to reduce heat transfer. Additionally, aluminum's high electrical conductivity makes it an excellent shield against electromagnetic radiation, as it can absorb and reflect a significant amount of electromagnetic waves. This property is utilized in various industries, including electronics and aerospace, to protect sensitive equipment from electromagnetic interference.</p>

- Q: This question asks about the environmental impact of aluminum foil, including its production, usage, and disposal.

- <p>Aluminum foil has a significant environmental impact. Its production requires large amounts of energy, contributing to greenhouse gas emissions. The mining of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction. Additionally, improper disposal of aluminum foil contributes to littering and can end up in landfills, where it takes centuries to decompose. However, aluminum is also highly recyclable, and recycling reduces energy consumption and emissions. Efforts to reduce aluminum foil usage and increase recycling are crucial for mitigating its environmental impact.</p>

- Q: Explain the distinction between pure aluminum and aluminum alloys, focusing on their composition and properties.

- <p>Pure aluminum is composed of aluminum alone, with a high degree of purity, typically over 99%. It is soft, malleable, and has good thermal and electrical conductivity. Aluminum alloys, on the other hand, are made by combining aluminum with other elements such as copper, magnesium, or silicon to enhance their strength, durability, and resistance to corrosion. These alloys are harder than pure aluminum and can be tailored for specific applications, making them more versatile for industrial use.</p>

- Q: This question asks about the various applications of aluminum in the construction industry.

- <p>Aluminum is widely used in construction due to its lightweight, high strength, and corrosion resistance. It is commonly used in window frames, door frames, curtain walls, and roofing systems for its durability and energy efficiency. Aluminum is also utilized in structural components such as beams and columns, as well as in the manufacturing of prefabricated buildings. Additionally, it is used in the electrical wiring and conduits within buildings due to its excellent conductivity. Its versatility makes it a popular choice for both residential and commercial construction projects.</p>

- Q: Explain the impact of using recycled aluminum on the environment.

- <p>Using recycled aluminum significantly reduces our environmental footprint. It requires only 5% of the energy needed to produce new aluminum from raw materials, thus conserving energy. Additionally, recycling aluminum reduces greenhouse gas emissions by up to 95% compared to aluminum production from bauxite ore. This lowers air pollution and helps combat climate change. Moreover, recycling aluminum conserves natural resources and reduces the need for mining, which has its own set of environmental impacts, including habitat destruction and water pollution. Overall, recycling aluminum is a sustainable practice that benefits the environment by reducing energy consumption, emissions, and resource extraction.</p>

- Q: Explain how the use of aluminum impacts energy consumption, including its production and recycling processes.

- <p>The use of aluminum has a significant impact on energy consumption, particularly in its production process. Aluminum is an energy-intensive material to produce, requiring large amounts of electricity to extract from its ore, bauxite, through a process called electrolysis. This process accounts for about 5% of global electricity consumption. However, aluminum is also highly recyclable, and recycling aluminum uses only 5% of the energy needed to produce it from raw materials. This makes aluminum recycling a more energy-efficient process, reducing the overall energy consumption related to aluminum use when recycling is prevalent.</p>

- Q: What are the positive environmental impacts associated with the use of aluminum?

- <p>Aluminum offers several environmental benefits. It is highly recyclable, which means it can be reused multiple times without losing its properties, reducing the need for raw materials and the energy required for extraction and processing. Aluminum is also lightweight, which can reduce fuel consumption and emissions in transportation. Additionally, aluminum is a good conductor of heat and electricity, making it energy-efficient in various applications such as insulation and electrical wiring. Its durability and resistance to corrosion mean it lasts longer, reducing waste and the need for frequent replacements.</p>

- Q: Is aluminum a suitable material for constructing aerospace structures?

- <p>Yes, aluminum is widely used in aerospace structures due to its high strength-to-weight ratio, corrosion resistance, and ease of fabrication. It is particularly favored for aircraft frames, wings, and fuselage components. Aluminum alloys are also used in spacecraft and satellite structures for their lightweight properties and ability to withstand extreme temperatures.</p>

- Q: Is it possible to utilize aluminum as a material for food containers?

- <p>Yes, aluminum is commonly used to make food containers due to its lightweight, durability, and good thermal conductivity. It's important to note that aluminum containers are often coated or lined with materials like plastic or enamel to prevent direct contact with food, as aluminum can react with acidic or alkaline foods and potentially leach into the food. Additionally, while aluminum is generally safe, there are concerns about its long-term health effects, so its use in food containers is regulated to ensure safety.</p>

Send your message to us

Aluminum Hot Rolled Circle Sheet AA1100 H14

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords