Hot Dipped Galvanized Drywall / Surface Regular Spangle

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

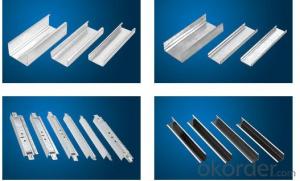

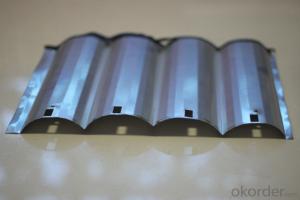

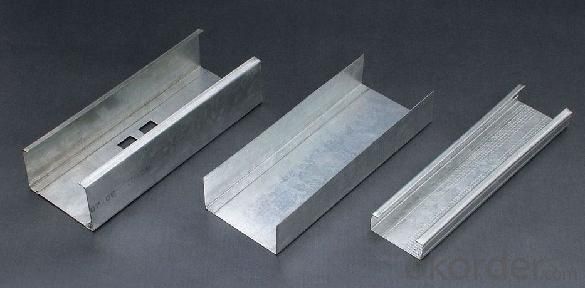

Drywall studs and tracks

Metal studs and tracks

Galvanized steel c profiles

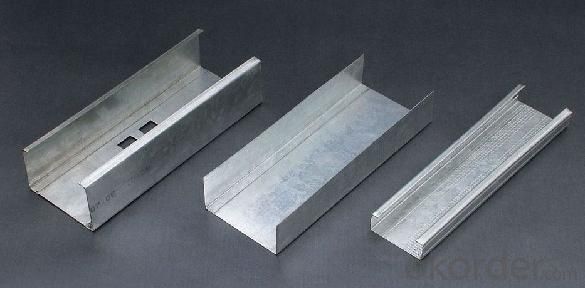

Hot dipped zinc galvanized.

Surface regular spangle

Easy to fix up

All kinds of types

Good rust-Proof function

Drywall Stud & Track and Furring Channel /c channel metal stud

Drywall Stud and Channel, for Ceiling Suspension and Partition Wall System.

Drywall Stud and Channel

Metal Profile, Drywall Stud and Track

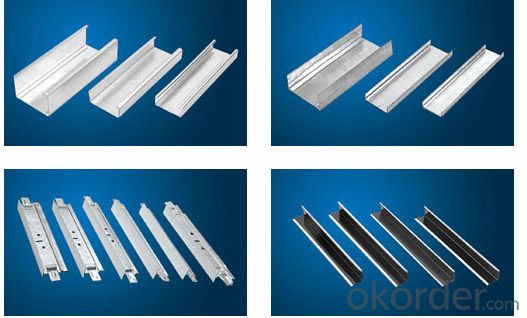

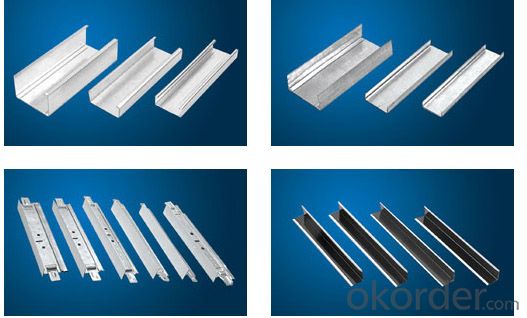

Regular Specification for Ceiling Suspension System:

DU38 38*12*3000/6000*0.8 / 1.0mm

DU50 50*15*3000/6000*1.0 / 1.2mm

DU60 60*27*3000/6000*1.2mm

DC50 50*15*3000/6000*0.38 / 0.45mm

50*19*3000/6000*0.38 / 0.45 / 0.5mm

DC60 60*27*3000/6000*0.6mm

Regular Specification for Partition Wall System:

QC75 75*35*3000/6000*0.5/ 0.6 / 0.7mm

75*40*3000/6000*0.6mm

75*45*3000/6000*0.6 / 0.7mm

75*50*3000/6000*0.6mm

QC100 100*45*3000/6000*0.7mm

100*50*3000/6000*0.7mm

QU75 75*35*3000/6000*0.5 / 0.6 / 0.7mm

75*40*3000*6000*0.6mm

QU100 100*35*3000/6000*0.7mm

100*40*3000/6000*0.7mm

Application

1. used for the permanent constructional structure such as embankment, harbors, docks, retaining walls, anti-earthquake reinforcement project, flood gates, etc

2. used for the provisional structure to seal the mountain, provisionally to retain the wall, to cut off the river, to cofferdam, to lay the pipeline and to ward off the earth, the water or the sand

3. used for the flood-fighting and emergency rescues to prevent the flood, collapse, sink or sediment flow, etc.

- Q: The highest quality i have seen is 9260 and i want to know if there is a higher quality steel.

- Types of steel are one issue. But the quality of steel no matter what type is even more important. The only way to be sure that you are getting a good blade is to buy from someone that already has a reputation for producing great blades. Stop the questions about who thinks what type of steel is best and investigate the steel blades offered by companies like Bugei Trading company. they have good blades. Opinions vary, but Bugei has proven that they make good swords. That is all that is needed to be known. Any questions you have are best directed to them, not here.

- Q: What is the cost of a steel coil?

- The cost of a steel coil can vary depending on several factors such as the type of steel, size, weight, and market conditions. It is best to contact a steel supplier or manufacturer for an accurate and up-to-date price quote.

- Q: Hello. No freakin' website has no dam info on what products have carbon steel in them. I know it's in cooking equipment and tools, but what tools?i.e It's in a wrench or strainerSo what products have carbon steel in them?

- there are too many products that have carbon steel in them. just ask yourself whether it rusts, if it does then it has carbon steel. If not then it probably isn't.

- Q: What are the challenges in coil slitting for thin gauge materials?

- Successfully operating coil slitting for thin gauge materials involves addressing a specific set of challenges. One major challenge is ensuring the proper handling and stability of the thin gauge material. The material's susceptibility to deformation, wrinkling, or tearing increases as it becomes thinner. To tackle this, careful attention must be given to the handling equipment and techniques used during the slitting process. This is necessary to maintain the appropriate tension and support throughout the operation. Another challenge is maintaining consistent and precise slitting widths. Thin gauge materials are often used in applications where accuracy is crucial, such as electronic components or automotive parts. Any variation in the slitting width can cause functional defects or assembly problems. Achieving precise slitting widths in thin gauge materials requires the use of high-quality slitting knives, well-maintained slitting machinery, and accurate tension control systems. In addition, thin gauge materials are more prone to surface defects, such as scratches or burrs, during the slitting process. These defects can impact the material's appearance, performance, or even its safety. To minimize the occurrence of surface defects, it is important to carefully select slitting knives and regularly maintain the slitting machinery. Furthermore, thin gauge materials often possess a higher yield strength, making them more resistant to deformation. This poses a challenge when it comes to achieving clean and straight edges during the slitting process. Special considerations must be taken to ensure that the slitting knives are sharp and properly aligned, allowing for clean cuts without introducing any edge defects. Lastly, thin gauge materials are generally more sensitive to external factors such as temperature, humidity, or static electricity. These factors can affect the material's dimensional stability, resulting in variations in slitting width or other quality issues. Therefore, it is crucial to establish appropriate environmental conditions and implement effective anti-static measures to minimize the impact of these factors. To summarize, the challenges associated with coil slitting for thin gauge materials revolve around handling and stability, maintaining precise slitting widths, minimizing surface defects, achieving clean and straight edges, and mitigating the influence of external factors. Overcoming these challenges requires a combination of suitable equipment, techniques, and operational controls to ensure high-quality slitting outcomes.

- Q: How are steel coils labeled for identification?

- Steel coils are typically labeled for identification using tags or stickers that contain important information such as the grade, size, weight, and production details of the coil. Additionally, some coils may also have unique identification numbers or barcodes for easier tracking and inventory management.

- Q: Why cold rolled stainless steel sheet is lower than cold rolled stainless steel coil?

- 304 stainless steel coil 2.0*1219*C spot price 18 thousand and 100 / ton, general tolerance at about 1.8mm.Coil price * actual thickness / reference thickness = flat price1.81*1.8/2=16.29

- Q: What processes and materials are used in the production of chrome steel

- Go to the process section and find point 6 (explains when alloys are added). Chrome is added at this point, usually in the form of ferrochrome alloy (FeCr). Many kinds of chrome steel also contain nickel. The strengthening effect on steel by forming stable carbide grains at the grain boundaries and the strong increase in corrosion resistance made chromium an important alloying material for steel. The high speed tool steels contain between 3 and 5% chromium.

- Q: How are steel coils used in the production of automotive suspension systems?

- Steel coils are used in the production of automotive suspension systems as they provide the necessary support and flexibility to absorb shocks and vibrations. These coils are typically used in the construction of coil springs, which are then integrated into the suspension system to ensure a smooth and comfortable ride for the vehicle.

- Q: What are the applications of steel coils in automotive manufacturing?

- Steel coils have various applications in automotive manufacturing. They are used primarily for the production of car bodies, as well as for other components such as doors, hoods, fenders, and trunk lids. Steel coils provide high strength, durability, and formability, making them suitable for creating robust and safe vehicles. Additionally, they offer excellent resistance to corrosion and can be easily molded into complex shapes, ensuring the desired design aesthetics and functionality.

- Q: What are the typical lead times for steel coil orders?

- The typical lead times for steel coil orders vary depending on factors such as the supplier, quantity, and specifications required. However, lead times can range from a few weeks to several months, with an average of 6-8 weeks being common.

Send your message to us

Hot Dipped Galvanized Drywall / Surface Regular Spangle

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords