Hot-dip Galvanized Steel Coil for Dry-wall Inside Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25000 m

- Supply Capability:

- 1000000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Hot-dip Galvanized Steel Description:

Hot-dip Galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process.Along with it many kinds of new technology and new process of global cold rolling production have been applied. Therefore the quality of the goods could be guaranteed. The product is widely used in outdoor and interior decoration, furnishing manufacturing, home appliance, automobile etc.

2.Main Features of Hot-dip Galvanized Steel:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

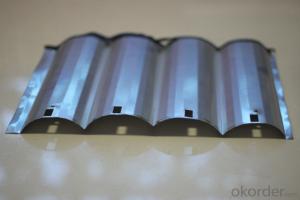

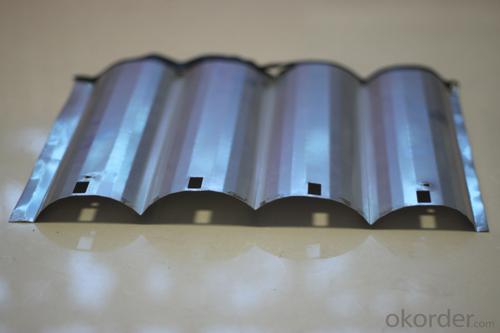

3. Hot-dip Galvanized Steel Images

4.Hot-dip Galvanized Steel Specification

Standard: ASTM A653M,EN10327,JIS G 3302

Grade: CS, DX51D+Z,SGCC

Thickness: 0.15mm~3.5mm

Width: 1250,600-1250mm

Coil weight:3-10 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Hot-dip Galvanized Steel

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: Is polystyrene sandwich board flammable?

- In general, the benzene board is flammable, but there is a flame retardant type, is the type of self-extinguishing. Usually used as building materials. The other is basically flammable.

- Q: Glass wool cotton color steel composite panels, also known as sandwich panels should be how to do re-test? Is it good to do it?

- Do the bare board re-test or do complex panel to see your design requirements and product record is how to prepare. Sometimes it is compound re-examination

- Q: What are the sandwich panels used in steel roofs? How much is the price?

- There are two kinds of steel panels used in steel roofs, one is called sandwich panels, that is, the factory has been the roof of the inner and outer color plate and the middle of the insulation layer composite; the other is called composite board , That is, the roof of the site at the site will be inside and outside the color plate and the middle of the insulation layer installed together. The advantage of the sandwich panel is because the factory has been compounded, so the site is quick and easy to install; the shortcomings are limited by the transport, the length is generally within 12 meters, the length of the slope is greater than the roof of the hidden water leakage. Because of its different insulation materials, one for the polystyrene sandwich panels, commonly known as foam board, the other for the polyurethane sandwich panels. Specifications are generally 50mm, 75mm, 100mm thick, the main use of the South 50mm thick board, the price according to the origin of color plate inside and outside the different, different thickness will be a difference to conventional 50mm thick, inside and outside the color plate for the OKorder Baosteel 0.5mm board For example, the unit price of about 65 yuan / m2, the land prices will be different Above the thickness of the board for each additional 15 yuan / m2. The advantages of composite panels due to the production in the field compound, you can ensure that the slope of a long slope, there is no leakage of hidden dangers; the disadvantage is that the installation of a little trouble. Thickness and price of the same as above

- Q: Color steel rock wool sandwich board 50mm per square meter how much money

- The price by region, quality and demand to go, Tianjin is rock wool board manufacturers more cities, a single rock wool board, then many can do 40 or so per square meter

- Q: EPS corrugated composite board and corrugated sandwich board What is the difference, 50MMEPS corrugated composite board (0.5 on the next 0.4) to do the plant roof construction process is how The price is almost a square?

- EPS corrugated composite board is a corrugated sandwich board, according to the core of the different corrugated sandwich panels are divided into EPS corrugated sandwich panels (that is, EPS), extruded sandwich panels, polyurethane sandwich panels and rock wool sandwich Plate and so on. Construction is the steel structure plus sandwich panels.

- Q: How to calculate the force of the sandwich panel

- Are generally estimated that we are doing this. Do not know how to calculate, but how many people we have to do the number of board

- Q: Sandwich board insulation roof sets what the amount of

- The so-called sandwich panels, in fact, should be color steel insulation board, right? If you can, you can set the color steel roof, but under normal circumstances the color steel roof is a single layer of color plate, you are the insulation board, you only need to take color steel roof and then the quota inside the single layer of steel plate for color steel Insulation sandwich board so that the provinces and cities are not the same as the amount of fixed content, the specific depends on your local quota requirements.

- Q: in a sandwich panels is there a formula to calculate the amount of foam in the square meter?

- V =1*t where t is the thickness of the foam in meters.

- Q: We are the construction unit to the scene into the decoration with the sandwich panels and fire retardant coating supervision requirements were re-test and then also use a good brush-resistant paint sandwich panels to do re-examination Will this want to detect what the purpose of what is the detection of the project. Good people to help answer Thank you

- Testing items, the general requirements in the relevant norms, if there is no required material, you can not do the retest.

- Q: Color steel polystyrene sandwich panel specifications 0.4 * 0.3 * 50mm, of which 0.3,0.4,50 size, respectively, where the size

- Do not know what you say 0.3,0.4 unit of measurement is rice or centimeters. If it is followed by the 50 mm unit that is consistent, it basically can not say it! However, on this color steel to understand the words, 50 mm refers to the thickness. 0.4,0.3 units should be meters, so that should be 0.4 meters long, 0.3 meters wide, 0.05 meters thick polystyrene board.

Send your message to us

Hot-dip Galvanized Steel Coil for Dry-wall Inside Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25000 m

- Supply Capability:

- 1000000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords