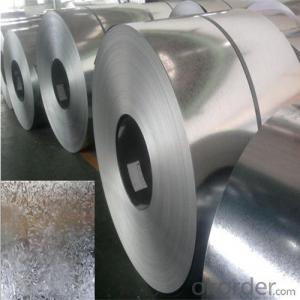

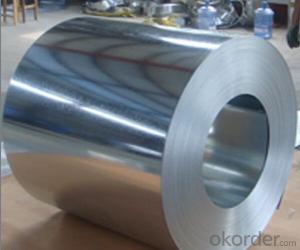

High-Quality Hot Dipped Galvanized Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Galvanized steel coils, Zinc 90 g

Regular spangle, chromated & unoiled

SIZE (MM) MOQ (MTS)

0.78 x 1000 60

0.85 x 1000 60

0.98 x 1000 60

1.08 x 1000 60

0.58 x 1200 60

0.78 x 1200 60

0.88 x 1200 60

0.98 x 1200 60

1.08 x 1200 60

1.18 x 1200 60

1.40 x 1200 60

2.20 x 1200 60

2.60 x 1200 60

3.60 x 1200 60

COIL ID: 508MM / 610MM

COIL WEIGHT: 12MTS MAX

PAYMENT: 100% LC AT SIGHT OR T/T WITH 30% DOWNPAYMENT

SHIPMENT: WITHIN 60 DAYS AFTER LC ISSUING DATE

- Q: Having a greater amount than 2% carbon in steel causes steel to suddenly become brittle. Why is this?

- Carbon fiber has better tensile capability then steel meaning its better while pulled aside. Plus you could mould the fiber to make autos-or homes-out of carbon fiber.

- Q: I want to design and fab a steel helmet like that in the latest Batman cartoon movie. Only problem I can foresee is staining the metal red.

- Yes you can, steel is a very storng metal. Source - www.qualitas-steel-doors .uk/

- Q: I want to anodize steel using heat. some steel turns gray instead of coloring when I heat it up using a torch.

- Steel doesn't anodize in the sense that aluminum and some other metals do. However, it can be heat-colored. The trick is to clean the surface first (it must be oxide free), then heat gently until the colors appear. These are called temper colors in steel. They are due to a thin adherent layer of oxide that forms and thickens as temperature is increased. They are quite temperature dependent. As the steel is heated, the first color to appear is pale yellow. This will progress through darker yellows, browns, purples, and blues as the temperature rises. Above blue, the oxide becomes the gray/black color you are apparently getting - this is the result of heating too fast and too hot. See the chart at the site below for colors in plain carbon steel. Note that the temperatures are pretty low - It all starts around 400 F and if you go above 600 F the show's all over.

- Q: How are steel coils inspected for color consistency using colorimetry?

- Steel coils can be inspected for color consistency using colorimetry by measuring the color of the surface using a spectrophotometer. This device analyzes the reflected light and provides objective and precise color data. By comparing the color measurements of different areas of the coil, any variations in color consistency can be identified, allowing for quality control and ensuring the desired color uniformity throughout the coil.

- Q: How are steel coils processed for heat treatment?

- Steel coils are typically processed for heat treatment by first being cleaned and prepped to remove any contaminants. They are then heated to a specific temperature and held at that temperature for a predetermined amount of time. After the desired heat treatment process is completed, the coils are cooled down gradually to ensure they retain the desired properties.

- Q: How are steel coils used in the manufacturing of transmission systems?

- Steel coils are used in the manufacturing of transmission systems to create various components such as gears, shafts, and bearings. These coils are often transformed into flat sheets or strips, which are then shaped and processed to form the required parts. The strength and durability of steel make it an ideal material for transmission systems as it can withstand the high stress and torque associated with transmitting power from the engine to the wheels efficiently and reliably.

- Q: Aluminum alloy rolling doors and color steel shutter door that good

- Among them, aluminum alloy rolling doors and ordinary rolling doors, both from the appearance, environmental protection or safety, have considerable advantages. Aluminum Alloy doors can be sprayed on the surface of various colors and patterns, but also with the concavity of the wood, sand grain coated, highlight the noble temperament, improve grades, if it is used in shops, you can let your talent shows itself in many shops in the.

- Q: Are steel coils used in automotive manufacturing?

- Yes, steel coils are commonly used in automotive manufacturing. They are used to produce various components such as body panels, chassis parts, and structural reinforcements due to their strength, durability, and formability.

- Q: How are steel coils used in the automotive stamping process?

- Steel coils are a critical component in the automotive stamping process. These coils are essentially large rolls of steel that are unwound and fed into stamping machines. The coils are typically made of high-quality steel and come in various thicknesses and widths to meet the specific requirements of different automotive parts. During the stamping process, the steel coils are fed through a series of dies and presses that shape and form the metal into the desired automotive components. The coils are unwound and passed through a straightener to remove any bends or twists, ensuring a smooth and consistent feed into the stamping machine. The stamping machine then uses a combination of hydraulic or mechanical force to press the steel coil against a die, which is a specially designed mold that gives shape to the metal. The die is often made of hardened steel to withstand the pressure and provide accurate and repeatable results. The steel coil is fed into the stamping machine at a high speed, and as it passes through the die, the metal is formed into various automotive parts such as body panels, doors, hoods, fenders, and other structural components. The stamping process allows for high precision and consistency in producing these parts, ensuring they meet the required specifications and tolerances. Once the metal is formed, it may undergo additional processes such as trimming, piercing, or bending to achieve the final shape. These processes are often performed in subsequent stamping stations or by using progressive dies that combine multiple operations into a single pass. Overall, steel coils play a vital role in the automotive stamping process as they provide the raw material required to produce various components. The use of steel ensures the necessary strength, durability, and safety of the automotive parts while maintaining cost-effectiveness and mass production capabilities.

- Q: How are steel coils packaged for shipping?

- Steel coils are typically packaged for shipping by being tightly wound and secured with steel bands or straps. They are then placed on wooden pallets or in steel cradles to ensure stability during transportation. Additionally, protective packaging materials such as plastic or cardboard may be used to prevent damage from moisture, dust, or other external factors.

Send your message to us

High-Quality Hot Dipped Galvanized Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords