Hot-Dip Galvanized Steel of Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

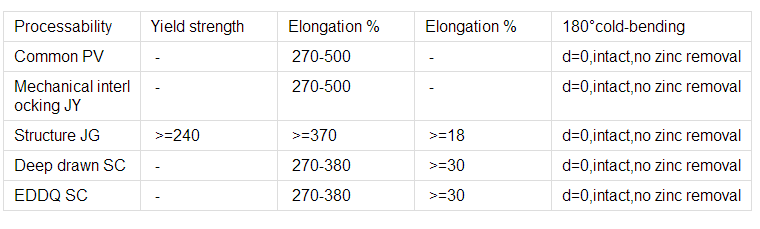

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: What is the average surface finish tolerance for steel coils?

- The average surface finish tolerance for steel coils can vary depending on the specific requirements and standards set by the industry or customer. Generally, it ranges from 10 to 20 micro-inches (0.25 to 0.5 micrometers), but it is important to consult the relevant specifications for the specific application.

- Q: also what are the factors of location of these steel plants

- iron ore comes from mines in North America, but also abroad. I think the majority of ore comes from mines in Michigan, Minnesota, and Canada. reason that steel plants are near great lakes is because the car industry is there... they are the major consumer of steel...

- Q: That's my question, well that and:Steel Pick + Electric Guitar = Trashed Guitar?:D

- That's not a question, it's a statement. And how would using any kind of pick trash a guitar? At worst it would harm a $5 set of strings, not the guitar.

- Q: What are the different types of steel coatings used on coils?

- There are several types of steel coatings used on coils, including galvanized coatings, galvannealed coatings, and organic coatings.

- Q: What are the main factors to consider when selecting a steel coil supplier?

- When selecting a steel coil supplier, some of the main factors to consider include the supplier's reputation and experience in the industry, the quality and consistency of their products, their ability to meet your specific requirements and timelines, their customer service and support, as well as their pricing and overall value proposition.

- Q: How are steel coils used in the manufacturing of construction excavators?

- Steel coils are used in the manufacturing of construction excavators as they are often the primary material for constructing the structural components of the excavator. These coils are typically processed and shaped into various parts, such as the chassis, boom, arm, and bucket, providing the necessary strength and durability required for heavy-duty construction work.

- Q: How are steel coils used in appliances?

- Steel coils are used in appliances to generate heat or create magnetic fields. They are commonly found in stovetops, ovens, and refrigerators, where they are responsible for heating elements or powering motors.

- Q: How are steel coils used in the manufacturing of storage racks?

- Steel coils are used in the manufacturing of storage racks by being cut and formed into structural components, such as beams and columns, which provide the necessary strength and durability to support the weight of stored items. These coils are processed through various machines and techniques, including bending, welding, and painting, to create the final storage rack structures.

- Q: What are the challenges in storing and handling steel coils?

- Storing and handling steel coils present several challenges, including their sheer weight and size, which can make transportation and storage difficult. The coils need to be stored in a way that prevents damage and deformation, as steel coils are susceptible to rust, corrosion, and scratching. Additionally, ensuring proper ventilation and moisture control is crucial to prevent the growth of mold or moisture-related damage. Safety precautions must also be taken during handling and transportation to avoid accidents or injuries.

- Q: i have a pocket knife that is stainless steel that my mom found in the parking lot and i am wondering if oxygen peroxide will rust it? and if it dose is there something else i can use to get rid of the rust?

- Stainless steel does not rust, but It can get dulled. Oxygen peroxide will not hurt it.

Send your message to us

Hot-Dip Galvanized Steel of Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords