Hot dip galvanized steel coil SS GRADE 340 quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 34562 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

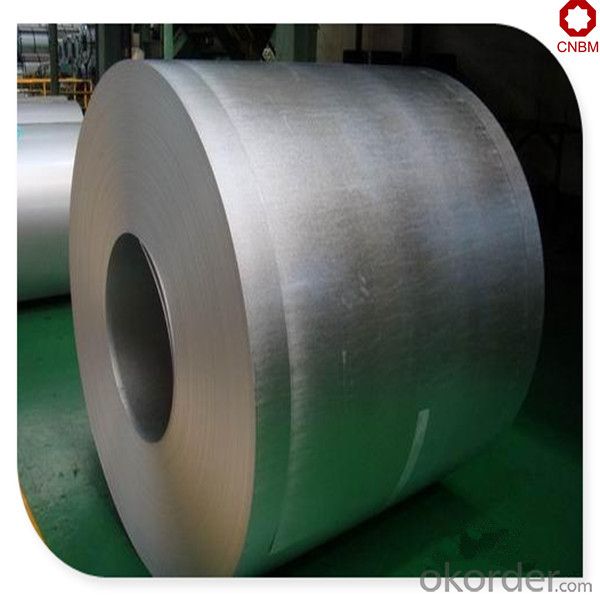

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

Pictures for stainless steel coil :

Standard and Grade :

Hot-dip galvanized steel coils | ||||

ASTM A653M-06a | EN10327:2004/ 10326:2004 | JISG 3302-2010 | AS-NZS 4534-2006 | |

Commercial quality | CS | DX51D+Z | SGCC | G1+Z |

Structure steel | SS GRADE 230 | S220GD+Z | SGC340 | G250+Z |

SS GRADE 255 | S250GD+Z | SGC400 | G330+Z | |

SS GRADE 275 | S280GD+Z | SGC440 | G350+Z | |

SS GRADE 340 | S320GD+Z | SGC490 | G450+Z | |

SS GRADE550 | S350GD+Z | SGC570 | G550+Z | |

S550GD+Z | G550+Z | |||

FAQ

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers. For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for Freight Collect. Also you can have a visit to us, welcome to CNBM!

- Q: I want to know because I'm going to Hershey Park on Wednesday and Steel Force looks about the same size, so, I wanted to know. It's not that Steel Force is too big for me.

- steel force breaks the 200ft mark and is a steel out and back roller coaster. Tidal force is a water ride that is about 100 ft tall. If you can do Steel Force then you should be able to handle anything at Hersheypark. the on;y ride they have bigger is the Kissing Tower

- Q: How are steel coils used in the production of industrial storage tanks?

- Steel coils are commonly used in the production of industrial storage tanks as they provide the necessary strength and durability. The coils are processed and formed into tank shells, which are then welded together to create the tank structure. This ensures that the tank is capable of withstanding the pressure and weight of the stored materials.

- Q: I need a machine which can produce steel pipes, but I don't know where to look...If you want me to state dimensions etc. just say...Thanks :)

- I'll answer both those questions. Your first question is: Who can I buy a Steel Pipe Making Machine? To which I reply: anyone. I'd put great consideration on the age of the person you are giving this machine to, and perhaps their physical ability. Cripples don't work well with steel pipes. Unless you are...beating them with one. Second question is: Where can I buy a Steel Pipe Making Machine? My reply: OKorder, or Steel Pipe Makers Incorporated. You could probably just steal one out of their factories. They have billions, and the actual machines are no bigger than...a bus or two. Just pop one in your backpack on the way out. But honestly, I don't know where to get a steel pipe making machine. BUT! I do know where to get a steel pipe making machine making machine. Ask santa. (BTW: Why do you need the steel pipes? I smell conspiracy!)

- Q: What are the common coil thickness and width combinations available for steel coils?

- The common coil thickness and width combinations available for steel coils vary based on industry standards and specific requirements. However, some commonly available combinations include coil thicknesses ranging from 0.5mm to 3mm and coil widths ranging from 600mm to 1500mm. Ultimately, the specific thickness and width combination for steel coils will depend on the intended application and manufacturing capabilities.

- Q: How are steel coils used in the production of steel clips?

- Steel coils are used in the production of steel clips by being unwound and fed into a stamping machine, where the coils are cut into strips and then shaped into the desired clip form.

- Q: I have one and need info about it??....It has a wooden case around the steel necks.and 20 strings,Twin Tens.

- well, it was made sometime before 1981, because that's when Fender quit making 10 string steel guitars. Without any more information than what you've given me, it could be the Pedal 2000, the PS210, or the Artist Dual 10. Fender made steel guitars from the 1950s through 1981, so it could be from any time in there. I hope you have the pedals with it. The 10-string and dual 10-string models were quite expensive in their day. Unfortunately, if you're thinking of reselling it, you're probably not going to get a lot of money for it unless you find a pedal steel player, and like I said, having all the pedals is very important in that case. Anyway, hope this helped. Good luck. If I were you I'd learn to play it. Pedal steel players are always in demand.

- Q: Can steel coils be used in architectural applications?

- Architectural applications can indeed utilize steel coils. These coils possess versatility and can be transformed into various shapes and forms to match the distinctive design specifications of architectural ventures. They find utility in constructing structures such as buildings, bridges, and more, as well as in fabricating architectural elements like roofing, cladding, and facades. The utilization of steel coils in architectural applications presents several benefits. They exhibit exceptional durability, strength, and corrosion resistance, rendering them suitable for constructing enduring and low-maintenance structures. Steel coils can be customized in terms of thickness, width, and surface finish, granting architects the ability to achieve their desired aesthetic and functional objectives. Moreover, steel coils are renowned for their structural stability and load-bearing capacity, both of which are vital considerations in architectural designs. Their high strength-to-weight ratio makes them an ideal selection for creating spacious and open interior areas, as well as for supporting heavy loads in multi-story buildings. Additionally, steel coils are easily fabricated and installed, resulting in time and labor savings during the construction process. They can be efficiently molded, cut, and welded to create intricate shapes or architectural details. Additionally, steel coils can be pre-fabricated off-site, guaranteeing precision and quality control, and subsequently assembled on-site, reducing construction time and minimizing disruptions to the surrounding environment. All in all, steel coils present architects and designers with a wide array of possibilities in architectural applications. Whether it pertains to structural support, aesthetic appeal, or functional requirements, steel coils provide a dependable and versatile material option that can fulfill the demands of contemporary architectural projects.

- Q: Im looking at some knives and am wandering if they use good steel one is this case knife and its 54 dollars Do they use good steel or not Iv never had a good experience with Case but am wandering if they use good steel now? if you all have any other recommendations let me hear them I got my Selection from here so any others wont hurt. so basic break down does case use good steel know?

- Old Case Knives

- Q: What are the different methods of roll forming steel coils?

- There are several different methods of roll forming steel coils, including hot rolling, cold rolling, and continuous casting. Hot rolling involves heating the steel above its recrystallization temperature and then passing it through a series of rollers to shape it into the desired form. Cold rolling, on the other hand, is performed at room temperature and involves passing the steel through rollers to increase its strength and improve surface finish. Continuous casting is a method where molten steel is continuously poured into a mold and then cooled to form a solidified strip or slab. These methods offer different advantages and are used in various applications based on the desired properties of the steel product.

- Q: How are steel coils used in the manufacturing of construction bulldozers?

- Steel coils are used in the manufacturing of construction bulldozers as they provide the necessary strength and durability required for the heavy-duty components of the machine. These coils are typically shaped and welded to form the structural frame, blades, and bucket of the bulldozer, ensuring that it can withstand the rigorous demands of construction and earthmoving tasks.

Send your message to us

Hot dip galvanized steel coil SS GRADE 340 quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 34562 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords