Hot-Dip Galvanized Steel Coil Prime Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Hot-Dip Galvanized Steel Coil Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process.

It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc.

The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust.

It is especially useful for countless outdoor and industrial applications.

2.Main Features of Hot-Dip Galvanized Steel Coil:

• Base material for countless outdoor and industrial applications

• High corrosion resistance

• High strength

• Good formability

• Rust- proof ability

• Good visual effect

3.Hot-Dip Galvanized Steel Coil Images

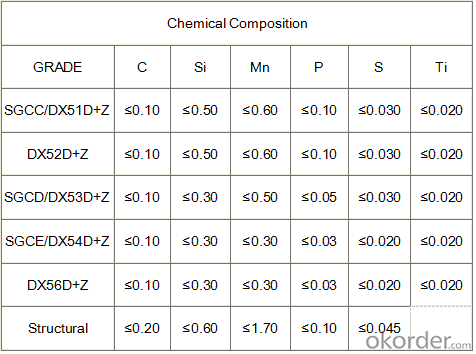

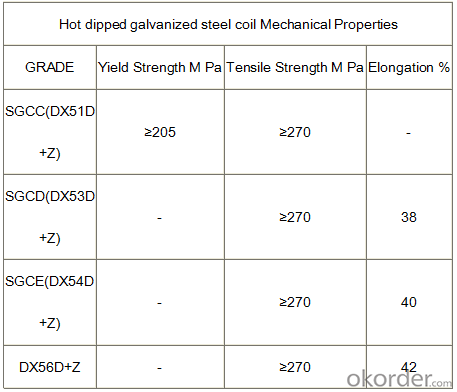

4. Hot-Dip Galvanized Steel Coil Specification

Operate Standard: ASTM A653M-04/JIS G3302/DIN EN10143/GBT 2518-2008

Grade : SGCD,SGCH, Q195,DX51D

Zinc coating :40-180g( as required)

Width:914-1250mm(914mm, 1215mm,1250mm,1000mm the most common)

Coil id:508mm/610mm

Coil weight: 4-10 MT(as required)

Surface: regular/mini/zero spangle, chromated, skin pass, dry etc.

s

5.FAQ of Hot-Dip Galvanized Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2) What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

3) How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: Which is more reactive? Zinc or Steel? And why?

- Zinc. Steel is an alloy consisting mostly out of iron, In the reactivity seris, zinc is more reactive than iron. Therefore, zinc is more reactive than steel

- Q: Are Danielle steel books good to read. Im 15 , but do I have to wait until Im a bit older.

- Wait until you are eighty, the dementia will make the process less painful Otherwise, you know best how mature you are and Danielle Steel is sugary romance, not really sex.

- Q: What is the average tensile strength of a steel coil?

- The average tensile strength of a steel coil can vary depending on the specific type and grade of steel being used. However, on average, steel coils tend to have a tensile strength ranging from 300 to 2,000 megapascals (MPa).

- Q: Can steel coils be stored vertically?

- Yes, steel coils can be stored vertically.

- Q: Eutectoid Steel

- Eutectic steel is used to produce pearlite, bainite, spheroidite and martensite steels. Those steels vary in strength, hardness and ductility. One uses martensite steel for example in razor blade manufacturing. Of course there is no end to the various uses of these steels.

- Q: Steel is a mixture of Iron Carbon . So , is steel a metal or non - metal ?

- Boeing is building the new 787 dreamliner almost completely out of composites. If you take a look at an Ashby chart (Strength vs. Density) you would see that there are composites that are as strong as steel but as dense as aluminum.

- Q: How are steel coils used in the production of steel pipes?

- Steel coils are an essential component in the production of steel pipes. These coils serve as the raw material that is used to manufacture the pipes. The first step in the process involves unwinding the steel coil and feeding it into a machine called a slitter. The slitter cuts the coil into narrower strips of the desired width. This width is crucial as it determines the diameter of the steel pipes that will be produced. Once the steel coil has been slit into strips, the next step is to feed these strips into another machine called a forming mill. The forming mill gradually shapes the strips into a cylindrical shape by passing them through a series of rollers. These rollers apply pressure and bend the strips until they take on the form of a pipe. To ensure the durability and strength of the pipes, they undergo a welding process. The ends of the strip are heated and fused together using a high-frequency electric current, resulting in a continuous weld along the length of the pipe. This weld provides structural integrity and prevents any leakage or weak spots in the pipe. After the welding process, the pipes go through a sizing and shaping process. They are passed through additional rollers and gradually reshaped to achieve the desired dimensions, including the final outer diameter and wall thickness. Finally, the pipes are cut to the desired length and undergo various finishing processes such as straightening, testing, and coating. These finishing steps ensure that the pipes meet the required specifications and are ready for use in various applications, such as plumbing, construction, and oil and gas industries. In summary, steel coils are the starting point for the production of steel pipes. They are slit, formed, welded, sized, shaped, and finished to create durable and high-quality pipes that can be used in a wide range of industries.

- Q: How are steel coils used in the production of shipbuilding materials?

- Steel coils are used in shipbuilding materials as they provide a versatile and durable solution. They can be processed into various shapes and sizes, including plates, beams, and sections, which are essential components for constructing ships. The coils are often cut and shaped to fit specific design requirements, offering strength and structural integrity to the ship's framework. Additionally, the coils are utilized in the fabrication of various shipbuilding components, such as hulls, decks, bulkheads, and superstructures, ensuring the vessels' resilience and stability.

- Q: What are the common surface treatments for galvanized steel coils?

- The common surface treatments for galvanized steel coils include passivation, chromate coating, and oiling. Passivation is a process where a thin layer of protective material, such as zinc phosphate or chromate, is applied onto the galvanized steel surface. This layer helps to enhance the corrosion resistance of the steel by providing a barrier against moisture and atmospheric elements. Passivation also improves the adhesion of subsequent coatings or paints that may be applied to the steel. Chromate coating, also known as chromating or chromate conversion coating, involves the application of a thin layer of chromate onto the galvanized steel surface. This coating provides an additional layer of protection against corrosion and improves the appearance of the steel. Chromate coatings can be clear or colored, depending on the desired aesthetic. Oiling is another common surface treatment for galvanized steel coils. This involves the application of a thin layer of oil onto the surface of the steel, which helps to prevent the formation of rust and corrosion during storage and transportation. Oiling also provides temporary protection against moisture and other environmental factors until the steel is further processed or used in its final application. These surface treatments are commonly used to enhance the performance, durability, and appearance of galvanized steel coils, ensuring that they can withstand harsh conditions and maintain their quality over time.

- Q: I know that the steel is significantly harder than when air cooled, but why is the quenched steel harder?

- Quenching results in smaller grains than air cooled. This means more boundaries, which means harder steel.

Send your message to us

Hot-Dip Galvanized Steel Coil Prime Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords