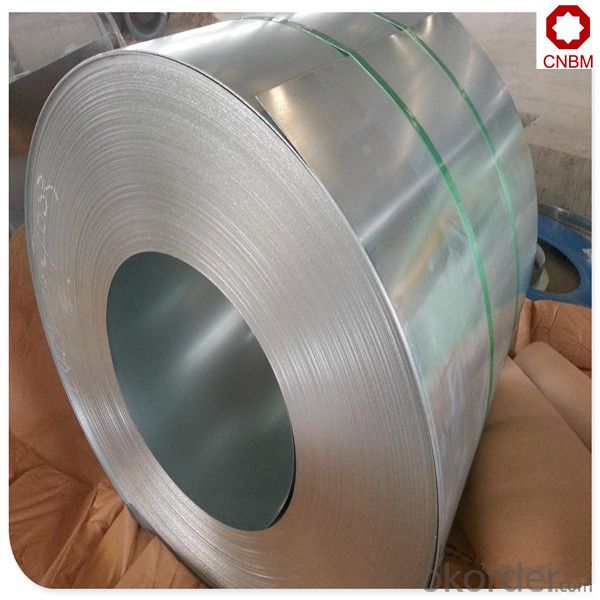

Hot-dip galvanized steel coil DX51D+Z quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

Standard and Grade :

Hot-dip galvanized steel coil | ||||

ASTM A653M-06a | EN10327:2004/ 10326:2004 | JISG 3302-2010 | AS-NZS 4534-2006 | |

Commercial quality | CS | DX51D+Z | SGCC | G1+Z |

Structure steel | SS GRADE 230 | S220GD+Z | SGC340 | G250+Z |

SS GRADE 255 | S250GD+Z | SGC400 | G330+Z | |

SS GRADE 275 | S280GD+Z | SGC440 | G350+Z | |

SS GRADE 340 | S320GD+Z | SGC490 | G450+Z | |

SS GRADE550 | S350GD+Z | SGC570 | G550+Z | |

S550GD+Z | G550+Z | |||

FAQ:

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers. For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for Freight Collect. Also you can have a visit to us, welcome to CNBM!

- Q: 7850kg/cu.m density is typical for all type of steel? like reibar, I- beam and so on

- 90% of the steels used today are plain mild carbon steels consisting of iron with less than 1% carbon content and as such have a density of about 7750 kg/cubic meter. Some special steels which have a significant percentage of alloying elements such as chrome or manganese or other elements will have greater density bringing the steel up to about 8000 kg / cubic meter. There are a greater many factors influencing the exact density of a steel. Even for steels of exactly the same content of iron , carbon and other alloying elements, there may be a difference ( very small mind you ) in density due to work hardening. The difference in this case is due to movement of dislocations which become locked in the grain boundaries and this forms a more dense crystal structure. For this same reason, the theoretical density of steel (which does not take into account dislocations) is greater than the measured density of steel.

- Q: What are the common methods of protecting steel coils from corrosion?

- Common methods of protecting steel coils from corrosion include applying a protective coating, such as zinc or paint, using corrosion inhibitors, storing coils in a controlled environment with low humidity, and implementing proper handling and packaging techniques to prevent moisture exposure.

- Q: What are the common methods of recoiling steel coils?

- The common methods of recoiling steel coils include slitting, rewinding, oscillating, and recoiling using a mandrel or a recoiler machine. Slitting involves cutting the wide coil into smaller widths, while rewinding involves rewinding the coil into a tighter, more compact roll. Oscillating is a method where the coil is wound back and forth to create a narrow, oscillating coil. Finally, recoiling using a mandrel or a recoiler machine involves winding the coil onto a mandrel or a spool to create a new coil of desired size and shape.

- Q: What are the common applications of steel coils?

- Steel coils have a wide range of applications across various industries, including automotive, construction, manufacturing, and appliance sectors. They are commonly used in the production of automobiles, machinery, and infrastructure components like bridges and buildings. Additionally, steel coils are utilized in the manufacturing of household appliances, such as refrigerators and washing machines. Their versatility, strength, and durability make steel coils a crucial material for many industrial applications.

- Q: What are the common coil inspection techniques?

- Some common coil inspection techniques include visual inspection, ultrasonic testing, magnetic particle inspection, eddy current testing, and dye penetrant testing.

- Q: How do we use steel ?plesase answer, its for homework xxx

- Iron and steel are used widely in the construction of roads, railways, infrastructure, and buildings. Most large modern structures, such as stadiums and skyscrapers, bridges, and airports, are supported by a steel skeleton. Even those with a concrete structure will employ steel for reinforcing. In addition to widespread use in major appliances and cars steel is used in a variety of other construction-related applications, such as bolts, nails, and screws.Other common applications include shipbuilding, pipeline transport, mining, aerospace, white goods, office furniture, steel wool, tools, and armour in the form of personal vests or vehicle armour.

- Q: I personally don't believe the story of 8 guys who flew small planes can navigate passenger jets into buildings hundreds of miles away with that precision. It just doesn't make sense.I am wondering what the story surrounding the molten steel was, how could molten steel have been produced when fuel from the planes wasn't hot enough (it melts at 2850 degrees)?

- that's just it: there wasn't very much molten steel for the very reason you point out. Jet fuel burns at 800° to 1500°F. This is not hot enough to melt structural steel. However, engineers say that for the World Trade Center towers to collapse, their steel frames didn't need to melt, they just had to lose some of their structural strength. Steel will lose about half its strength at 1,200 degrees F. The steel will also become distorted when heat is not a uniform temperature. after the collapse, a LOT of folks took a look at the remains. the result was the conclusion that the fire caused the central core of the building to weaken. When the floors collapsed one on top of the other, the weight was too much for the weaked core to bear, causing the result we are all familiar with. hope this helps

- Q: I've been looking into battle-ready katanas a lot lately. And I've come across some debates between the best forges and steels to be used for them. The functional katanas I use now are Musashi brand katanas, using 1045 carbon steel. They each cost roughly $200-$250. The straight carbon steels are mentioned in the debates, but they aren't very sophisticated in their design. Now the higher end of this middle class of katana ($250-$1000) uses higher carbon. spring, damascus, and other various steels and combinations. I've heard a lot about the strength of damascus steel and it's cutting power. But I look for more than that. I've also been looking at (and for) durability, flexibility, and how well it stands up to contact. So I guess what I'm asking is for the opinion of people who have used these steels, and an answer on what the community thinks is the best steel for a mid range ($250-$1000) battle-ready katana. Looking forward to some good answers.

- This Site Might Help You. RE: Best battle-ready katana steel? I've been looking into battle-ready katanas a lot lately. And I've come across some debates between the best forges and steels to be used for them. The functional katanas I use now are Musashi brand katanas, using 1045 carbon steel. They each cost roughly $200-$250. The straight carbon...

- Q: What are the common applications of hot-rolled steel coils?

- Hot-rolled steel coils are widely used in various industries due to their unique characteristics and versatility. Some of the common applications of hot-rolled steel coils include: 1. Automotive industry: Hot-rolled steel coils are extensively used in the automotive sector for manufacturing various components like frames, doors, hoods, wheels, and chassis. The high strength and formability of hot-rolled steel make it an ideal choice for producing durable and lightweight automotive parts. 2. Construction sector: Hot-rolled steel coils are widely used in construction projects for manufacturing structural components like beams, columns, and trusses. The high strength and ductility of hot-rolled steel make it suitable for withstanding heavy loads and providing structural stability. 3. Manufacturing industry: Hot-rolled steel coils find applications in the manufacturing sector for producing a wide range of products including machinery parts, pipes, tubes, and equipment. The excellent machinability and weldability of hot-rolled steel allow for easy fabrication and customization according to specific manufacturing requirements. 4. Energy sector: Hot-rolled steel coils are used in the energy sector for manufacturing pipelines, tanks, and other infrastructure required for oil and gas exploration, transmission, and storage. The corrosion resistance and strength of hot-rolled steel make it a preferred choice for such applications. 5. Appliances and furniture industry: Hot-rolled steel coils are used in the manufacturing of appliances like refrigerators, ovens, and washing machines, as well as for producing furniture components like frames and supports. The aesthetic appeal, durability, and cost-effectiveness of hot-rolled steel make it a popular choice in these industries. 6. Shipbuilding industry: Hot-rolled steel coils are extensively used in the shipbuilding sector for constructing various components like hulls, decks, and bulkheads. The high tensile strength and corrosion resistance of hot-rolled steel ensure the durability and longevity of ships in harsh marine environments. 7. Infrastructure and bridge construction: Hot-rolled steel coils are used in the construction of bridges, highways, and other infrastructure projects. The high strength and load-bearing capacity of hot-rolled steel make it suitable for supporting heavy traffic and withstanding dynamic loads. In summary, hot-rolled steel coils find applications in various industries including automotive, construction, manufacturing, energy, appliances and furniture, shipbuilding, and infrastructure. The unique properties of hot-rolled steel, such as high strength, formability, and versatility, make it an indispensable material for a wide range of applications.

- Q: I want a stainless steel refrigerator that doesn't leave fingerprints and I'm looking on Lowe's website but they have too many choices and i don't have a clue what they are. The have stainless, stainless look, stainless steel, monochromatic satina, and monochromatic stainless steel. Can anyone tell me what the heck those mean? lol

- Monochromatic Stainless Steel Definition

Send your message to us

Hot-dip galvanized steel coil DX51D+Z quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords