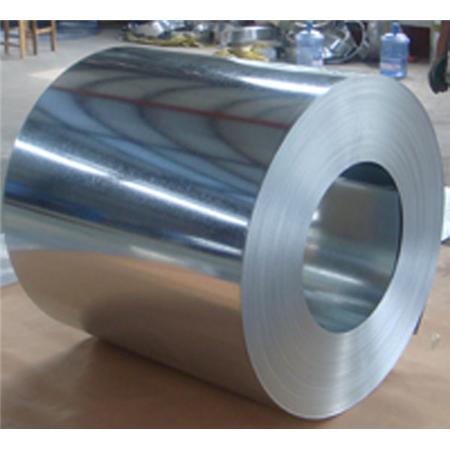

DX51 DHot dip galvanized steel coil

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 20000 Mt m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HOT DIP GALVANIZED STEEL COIL

specifications

Thickness:0.18-1.2mm

Width:762-1250mm

Zinc:40-140g

Spangle:zero spangle

Surface:chromate, oiled/unoiled, skin pass

Inner diameter: 508 or 610mm

Coil weight:3-20Mt

Application

(1)Guardrails, roofing, ventilation ducts, gutters and down spouts;

(2)Pre-paint and post paint applications, ceiling suspension bars, shutter door rails;

(3Auto parts, electrical appliances, refrigerator appliances, vending machines, washing machines, showcases and other structural use

Standard: ASTM A653/JIS G 3302/EN10327/GB2518

Packing style:standard dampproof, seaworthy export packing or according to customer's requirements

Payment Term: L/C AT SIGHT OR T/T

Production Days: 500Mt or less within 30 days after order/payment confirmed

If you have any need of GI or PPGI Coil,please feel free to contact me.

Alena

- Q: Can you reload spent casings if they are steel?

- you're not supposed to but if there's a will, there's a way. suppose it's the end of the world and you're just about to run out of ammunition, you can reload steel cases by drilling the primer pocket out to fit either a small boxer primer or large boxer primer. and drilling out a flash hole too. the cases must be from your gun and be able to chamber/extract without resizing. steel cases become brittle after a few uses, which become dangerous to reuse more than once. however if it's one of those situations you need ammo, it can be reloaded at low pressure a few dozen times, just give it a thorough inspection between reloading.

- Q: What are the common methods of preserving steel coils?

- Some common methods of preserving steel coils include applying protective coatings, such as oil or paint, to prevent corrosion and rust formation. Another method is using VCI (Vapor Corrosion Inhibitor) paper or film, which releases chemicals that prevent oxidation. Additionally, steel coils can be stored in climate-controlled environments or wrapped in moisture-resistant materials to minimize exposure to moisture and humidity, which can accelerate corrosion.

- Q: How are steel coils inspected for oil or rust residues?

- Oil or rust residues in steel coils are examined through a series of visual and physical checks. Trained personnel conduct the initial visual inspection, closely scrutinizing the steel surface for any indications of oil or rust residues. They look for discolouration, stains, or any unusual signs that could suggest the presence of contaminants. Besides the visual inspection, different techniques are employed to detect oil or rust residues. One commonly used method is solvent cleaning. A solvent is applied to the steel coil's surface, and if there are any oil or rust residues, they will dissolve and become visible. This enables inspectors to identify and eliminate any contaminants. Ultrasonic testing is another technique used for inspection. Ultrasonic waves are transmitted through the steel coil, and any variations in the reflections of these waves can indicate the presence of oil or rust residues. This non-destructive testing method provides a more comprehensive analysis of the steel's condition, ensuring a thorough inspection. In addition, specialized equipment such as magnetic particle inspection or eddy current testing may be utilized. Magnetic particle inspection involves applying magnetic particles to the steel surface, which will gather around areas with oil or rust residues. Similarly, eddy current testing employs electromagnetic induction to identify surface irregularities caused by contaminants. Overall, a combination of visual inspection and various testing techniques is employed to ensure a meticulous examination of steel coils for oil or rust residues. These rigorous inspections guarantee that the coils meet the required quality standards and are free from any contaminants that may compromise their performance or durability.

- Q: What are the common tests performed on steel coils?

- Common tests performed on steel coils include visual inspection, dimensional measurement, tensile strength testing, hardness testing, surface finish evaluation, and coating thickness measurement. Additionally, other specialized tests like bend testing, impact testing, and corrosion resistance testing may also be performed depending on the specific requirements and application of the steel coils.

- Q: Can steel coils be coated with organic materials?

- Yes, steel coils can be coated with organic materials.

- Q: i got the belly button ring from icing and its surgical steel are they the same things?

- yes they are same kind of steel

- Q: How are steel coils inspected for quality assurance?

- Quality assurance for steel coils involves a rigorous process that includes various tests and checks to ensure their quality. Initially, a visual inspection is carried out to identify surface defects like scratches, dents, or rust, ensuring the coils are in good condition and free from obvious flaws. Afterward, a dimensional inspection is performed to verify the coils' dimensions and tolerances. This involves measuring their width, thickness, and length to ensure they meet the specified requirements. Any deviations from the standard dimensions are noted and addressed. Moreover, mechanical testing is conducted to assess the strength and durability of the steel coils. Tensile tests are performed to measure their strength and elasticity, while impact tests evaluate their ability to withstand sudden loads or shocks. Furthermore, chemical analysis is undertaken to determine the composition and purity of the steel. Samples are taken from the coils and analyzed in a laboratory to check for impurities or elements that could affect the quality. To comply with industry standards, non-destructive testing methods like ultrasonic testing or magnetic particle inspection may be used. These methods can detect internal defects or irregularities that may not be visible to the naked eye. Additionally, surface treatment inspections, such as galvanization or coating checks, may be performed to ensure the protective layers are applied correctly and meet the necessary specifications. In summary, the quality assurance process for steel coils includes visual, dimensional, mechanical, chemical, and non-destructive testing methods. These thorough inspections guarantee that the steel coils meet the required quality standards and are suitable for their intended applications.

- Q: I saw this really pretty ring online and it was made of steel. Is this a good ring? If I were to wash my hands with it on, would it rust and turn my finger green?

- Steel rust is brown not green! Very much expected to be of one type of stainless steel, and you should have no problem.

- Q: How can I owe a Pre-engineered Steel Building?

- You just have to do small efforts for owing a steel building: Firstly you have to finalize a steel building company for construction work. After finalizing the steel building company, the next step is the paperwork - the agreements and contracts. Some steel building companies may also ask for a verbal approval for the factories to get the work started.

- Q: What are the weight ranges for steel coils?

- The weight ranges for steel coils can vary depending on the specific type and size, but they typically range from a few hundred kilograms to several metric tons.

Send your message to us

DX51 DHot dip galvanized steel coil

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 20000 Mt m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords