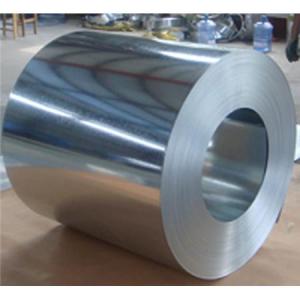

Hot-Dipped Galvanized Steel Coils (Dx51d+Z)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info.

Model NO.:Steel Coil 0005

Surface Treatment:Galvanized

Certification:ISO, SGS

Technique:Cold Rolled

Standard:ASTM, JIS, GB, AISI, DIN, BS

Application:Roof Boarding,Appliances Shell

Edge:Slit edge

Stock:Not Stock

Steel Grade:Dx51d+Z

Export Markets:Southeast Asia, Africa, Mid East, Eastern Asia

Additional Info.

Trademark:N/M OR OEM

Packing:3-5tons/Roll with Seaworthy Packages

HS Code:72104900

Production Capacity:6000tons Per Month

Product Description

Galvanized Steel Coil

Material: DX51D, DX52D, SGCC, SGCH, SPGC

Thickness: 0.13-0.7mm

Width: 750-1250mm(762mm, 914mm, 1000mm, 1200mm, 1219mm, 1250mm)

Zinc: 40g, 60g, 80g, 90, 100g, 120g, 140g, 180g, 200g, 250g, 275g and so on.

Spangle: Zero spangle, regular spangle or normal spangle

Surface treatment: Chromated and oiled, chromated and non-oiled

Packing: Export standard, plastic film+water proof paper + steel plate+ packing steel strip

Q&A

Acceptable payment term and way?

T/T,L/C, T/T + L/C, D/P

Acceptable price term

FOB CNF CIF DDU CPT

Do you accept OA payment terms?

Yes, sure, but it normally depending on the order value

Do you have QC team?

Yeah, sure, our QC team is very important, they will keep the qualitycontrol for our products.

What is the validity of your quotation?

Normally 7 days.

What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

What is your acceptable payment term?

TT,LC,OA etc

- Q: What temp does fire have to be to melt steel?

- more than 300° F

- Q: How are steel coils coated for corrosion resistance?

- Steel coils are typically coated for corrosion resistance using various methods such as hot-dip galvanizing, electroplating, or applying a protective layer of paint or powder coating.

- Q: What are the common methods of joining steel coils?

- Various techniques can be employed to join steel coils, depending on the desired outcome and specific application. Butt welding is a commonly utilized method wherein the two ends of the steel coils are aligned and welded together. Gas welding, electric resistance welding, or laser welding can be employed for this purpose. This technique yields a strong and continuous joint without the need for additional material. For temporary or low-stress applications where disassembly may be necessary, overlapping and stitching is an option. In this technique, one end of the steel coil is overlapped onto the other end and fastened together using mechanical means such as staples, nails, or screws. Mechanical couplings are another means of joining steel coils. These couplings are designed to fit over the coil ends and securely hold them together. They are commonly used in pipelines where the joint must be leak-proof and capable of withstanding high pressure. Adhesive bonding is a method that involves applying a suitable adhesive or bonding agent to the coil ends and pressing them together. This technique results in a clean and visually appealing joint, although the strength may vary depending on the adhesive used. Similar to overlapping and stitching, overlapping and welding involves overlapping the coil ends and welding them together. However, instead of using mechanical fasteners, welding is employed to create a stronger and more permanent joint. This method is frequently employed in structural applications that require high strength and durability. It should be noted that the selection of a joining method depends on factors such as the type of steel, application requirements, and desired joint strength. Careful consideration should be given to ensure that the chosen method is suitable for the specific project.

- Q: What are the different types of steel coil leveling methods?

- There are three main types of steel coil leveling methods: roller leveling, stretcher leveling, and temper leveling. Roller leveling involves passing the coil through a series of rollers to reduce its curvature and improve flatness. Stretcher leveling uses hydraulic or mechanical stretching to remove the coil's internal stresses and straighten it. Temper leveling, on the other hand, subjects the coil to a controlled heating and cooling process to achieve the desired flatness. Each method has its own advantages and is chosen based on the specific requirements of the steel coil.

- Q: i would like to know of any companies who buy shredded scrap steel

- We are one of the biggest steel mills in Asia. Under our group, we have steel mills in Thailand and Bangladesh. On the monthly basis, we purchase steel scrap HMS1/2 80:20 and the shredded ISRI210/211, ISRI211 by bulk and 20' container to Thailand and Bangladesh. Due to the limitation of our existing shredded steel scrap supplier, we need to get more supply of the shredded. Please contact us or offer us of ISRI 210/211 or ISRI211 CFR Chittagong, Bangladesh with 500mt - 2000mt per shipment by 20' container. If any questions, please feel free to contact us.

- Q: How are steel coils used in the manufacturing of agricultural irrigation systems?

- Steel coils are used in the manufacturing of agricultural irrigation systems as they are shaped and formed into various components such as pipes, tubes, and fittings. These coils provide strength, durability, and corrosion resistance, ensuring the longevity and reliability of the irrigation system.

- Q: What are the different methods of coil cutting for steel coils?

- There are several methods of coil cutting for steel coils, including slitting, shearing, and laser cutting. Slitting involves passing the coil through a set of circular blades to create multiple narrower strips. Shearing utilizes a straight blade to cut the coil into desired lengths. Laser cutting involves using a high-powered laser beam to precisely cut through the coil. Each method has its own advantages and is chosen based on the specific requirements and preferences of the manufacturer or end-user.

- Q: How are steel coils protected against corrosion?

- Steel coils are protected against corrosion through various methods such as applying protective coatings, galvanizing, or using corrosion inhibitors. These measures help to create a barrier between the steel surface and the surrounding environment, preventing the onset of corrosion and extending the lifespan of the coils.

- Q: Can steel coils be stored in unheated warehouses?

- Yes, steel coils can be stored in unheated warehouses. Steel coils are not typically affected by low temperatures, as they are durable and resistant to cold weather conditions. However, it is important to ensure that the warehouse is dry and free from moisture, as prolonged exposure to dampness can cause rust and corrosion on the steel coils.

- Q: I wrote in my assignment that mild steel has a high carbon content (4%).This is why it has its strong and rigid properties.. is this correct?

- Steel is defined as an alloy of iron and carbon (often supplemented by further materials) with a carbon content between 0.01 % and 2.06 %. 4% is in the realm of cast iron, which isn't quite as rigid as steel. Mild steel contains 0.16 - 0.29% carbon. You're off by more then a decimal.

Send your message to us

Hot-Dipped Galvanized Steel Coils (Dx51d+Z)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords