Hot-dip Galvanized Steel Coil DX51D+Z with Best Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

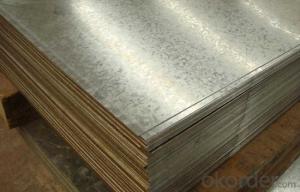

1.Hot-dip Galvanized Steel Coil DX51D+Z with Best Price

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.18mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: What are the different types of steel alloys used in coil manufacturing?

- There are several types of steel alloys used in coil manufacturing, including carbon steel, stainless steel, and high-strength low-alloy (HSLA) steel. Each alloy has different characteristics and properties that make it suitable for specific applications in coil manufacturing. Carbon steel is commonly used for general-purpose coils due to its affordability and versatility. Stainless steel is preferred for its corrosion resistance and aesthetic appeal, making it suitable for applications that require durability and a polished finish. HSLA steel, on the other hand, offers enhanced strength and toughness, making it ideal for demanding applications that require high performance and durability.

- Q: How are steel coils used in the production of metal fencing?

- Steel coils are used in the production of metal fencing as they serve as the raw material for creating the wire mesh that forms the structure of the fence. The steel coils are uncoiled and then passed through a series of machines that shape and weld them into the desired fence panels or rolls. These panels are then further processed and treated to enhance their durability and resistance to corrosion, ultimately resulting in high-quality metal fencing products.

- Q: Alright, First off i have an old plywood military box with galvanised steel corners, hinges etc (any part that must be strong) and its rusting! Some of the pieces have discoloration (like an oil stain on them) and other parts are full of this metallic dust. 1) Should i remove this box from my room?2) Is there any way or should i remove the powder on the part?3) Does this pose a serious health hazard?4) What are the oil stains?

- Wipe the powder of and the rest should be safe, unless you stub your toe on the rusty metal.

- Q: How are steel coils used in the production of steel clips?

- Steel coils are used in the production of steel clips by being unwound and fed into a machine, where they are cut, shaped, and formed into the desired clip design.

- Q: Steel Strings on your guitar or nylons? Why?

- Kind of a silly question. I use steel strings on my steel string guitars and nylon strings on my classical guitar. It's not something you have any choice in; steel string guitars must use steel strings and classical guitar must use nylon strings.

- Q: How are steel coils used in the production of steel pipes?

- Steel coils are an essential component in the production of steel pipes. These coils serve as the raw material that is used to manufacture the pipes. The first step in the process involves unwinding the steel coil and feeding it into a machine called a slitter. The slitter cuts the coil into narrower strips of the desired width. This width is crucial as it determines the diameter of the steel pipes that will be produced. Once the steel coil has been slit into strips, the next step is to feed these strips into another machine called a forming mill. The forming mill gradually shapes the strips into a cylindrical shape by passing them through a series of rollers. These rollers apply pressure and bend the strips until they take on the form of a pipe. To ensure the durability and strength of the pipes, they undergo a welding process. The ends of the strip are heated and fused together using a high-frequency electric current, resulting in a continuous weld along the length of the pipe. This weld provides structural integrity and prevents any leakage or weak spots in the pipe. After the welding process, the pipes go through a sizing and shaping process. They are passed through additional rollers and gradually reshaped to achieve the desired dimensions, including the final outer diameter and wall thickness. Finally, the pipes are cut to the desired length and undergo various finishing processes such as straightening, testing, and coating. These finishing steps ensure that the pipes meet the required specifications and are ready for use in various applications, such as plumbing, construction, and oil and gas industries. In summary, steel coils are the starting point for the production of steel pipes. They are slit, formed, welded, sized, shaped, and finished to create durable and high-quality pipes that can be used in a wide range of industries.

- Q: Why do we galvanise steel? Galvanised steel is steel coated with zinc.

- it prevents the steel from rusting. Zinc rusts too, but more slowly than steel, and it doesn't tend to eat away it's structure. Zinc coatings prevent oxidation of the protected metal by forming a barrier, and by acting as a sacrificial anode if this barrier is damaged. Zinc oxide is a fine white dust that (in contrast to iron oxide) does not cause a breakdown of the substrate's surface integrity as it is formed. Indeed the zinc oxide, if undisturbed, can act as a barrier to further oxidation, in a way similar to the protection afforded to aluminium and stainless steels by their oxide layers.

- Q: Are steel-capped boots safer than non-capped ones when working with horses? I have been told that sometimes if a horse steps on you, the steel crushing into your foot is more dangerous than if you just had normal wellies on, as at least with normal wellies there is some flexibility. Any horsey people out there got any experience with this? Thanks!

- In all my experience as a farrier steel toes have neither helped nor caused any problem. I would be a vary rare case that the horse would be able to collapse the steel and with that much force the steel bending would be the last of your problems because your foot would have been completely destroyed without it. I agree with being alert a nd trying to get your feet out of the way. The few times i've been hurt the horse has chopped down toe first on the arch of my foot high above where there steel is any way. I've oddly enough never had a problem with getting my toes stepped on it really doen't seem to hurt if they land flat footed.

- Q: Are steel coils used in the oil and gas industry?

- Yes, steel coils are commonly used in the oil and gas industry for various applications such as pipeline construction, storage tanks, and drilling equipment. The strength, durability, and corrosion resistance of steel make it an ideal material for handling the demanding conditions in this industry.

- Q: How are steel coils used in the production of elevator components?

- Steel coils are an essential component in the production of elevator components. These coils are made from high-quality steel that is specifically designed to meet the demanding requirements of elevator manufacturing. One of the primary uses of steel coils in elevator production is for the manufacturing of elevator doors. The coils are processed into flat sheets and then cut into the desired dimensions to create the doors. These doors require strength and durability to withstand frequent use and ensure passenger safety. Steel coils provide the necessary structural integrity and resistance to deformation that is necessary for elevator doors. Additionally, steel coils are also used in the manufacturing of elevator cabins. The coils are processed and formed into various shapes to create the walls and flooring of the elevator cabins. The strength and rigidity of steel make it an ideal material for this purpose, as it can withstand heavy loads and provide a secure and stable environment for passengers. Moreover, steel coils are used in the production of elevator shafts. The coils are rolled into cylindrical shapes and welded together to create the structural framework of the elevator shafts. These shafts need to be strong and rigid to support the weight of the elevator and ensure smooth and safe vertical movement. Steel coils provide the necessary strength, stability, and load-bearing capacity for this critical component of elevator systems. In summary, steel coils are vital in the production of elevator components such as doors, cabins, and shafts. Their strength, durability, and versatility make them suitable for creating reliable and safe elevator systems that can transport passengers efficiently and securely.

Send your message to us

Hot-dip Galvanized Steel Coil DX51D+Z with Best Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords