Hot-Dip Galvanized Steel Coil Best Quality with Beautiful Surface

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

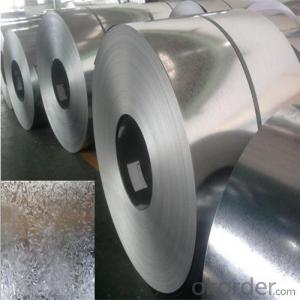

Hot-Dip Galvanized Steel Coil Best Quality with Beautiful Surface

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

3. Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.18mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Surface structure: zero spangle, regular spangle or minimum spangle

5.FAQ of Hot-Dip Galvanized Steel Sheet

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: I was just thinking, is their a way to make steel qualities inherent in concrete, therefore eliminating the need for re bar?

- There is an iron powder reinforced concrete flooring that improves abrasion resistance. However, you cannot get the tensile strength enhancement that is possible with rebar.

- Q: Can steel coils be used in the production of medical equipment?

- Yes, steel coils can be used in the production of medical equipment. Steel is a strong and durable material that can provide structural support and stability to various medical devices and equipment. It is commonly used in the manufacturing of instruments, surgical tools, and machinery used in medical settings.

- Q: I've been looking for lots of info on this steel. Cold Steel uses it now in their knives replacing the AUS-8 steel. I was hoping somebody had a knife with this steel who could give me some real first hand knowledge not just numbers. Thanks!

- I carry a french knife that has been made the same way for 400 years , the manufacturer is called Opinel,...they fold up and are carbon steel and for what I do are very period correct for anything from 1700's through 1800's...any way they are very good and come in like 5 different sizes.... check and see if they have a web site....

- Q: a picture of the atomic structure of carbon steel

- This is actually a quite complex question... The atomic arrangement in steels can be controlled over a pretty wide range of different structures. This is really the fundamental reason why steel is such a commonly used material. The different atomic structures produce different physical properties so metallurgists have developed many different processes to control the atomic structure to get the properties they want. One simple answer is that Fe is BCC, body centered cubic at room temperature at equilibrium conditions. When you heat Fe up, it transforms to FCC, face centered cubic. If you continue heating Fe, it goes back to BCC, then it melts. The addition of C makes these structures (and the transformation temperatures) different. Deviating from equilibrium conditions by, for example, cooling very quickly (quenching) creates different atomic structures (one of the most important is known as martensite). Depending on how much C is in the steel, you can also have two different atomic structures (two different phases) present in equilibirum, for example, pearlite which is a mix of alpha Fe (BCC) and iron carbide Fe3C (orthorombic crystal structure). So... you need to think a little more about exactly what you want a picture of. I hope this helps

- Q: What are the surface treatments for steel coils?

- Some common surface treatments for steel coils include galvanizing, painting, and coating. These treatments are applied to protect the steel from corrosion, improve its appearance, and enhance its durability.

- Q: If steel can rust with saltwater... then why are ships made of steel? can't we just use other metals like aluminium etc?

- aluminium is not good in saltwater Steel rusts in fresh air let alone saltwater but its alot cheaper than other mass produced metals you can rivet or weld it cheaply unlike stainless steel or Aluminium We could make them of wood but thats been tried Glass fibre and plastic is good for small boats but to do and Aircraft carrier size ship i doubt it

- Q: How do steel coils contribute to the construction equipment industry?

- The construction equipment industry relies heavily on steel coils as they are vital for manufacturing various construction machinery and equipment. These coils, made from high-quality steel, are crucial components used in the fabrication of a wide range of construction equipment, including cranes, bulldozers, excavators, loaders, and forklifts. The main contribution of steel coils to the construction equipment industry lies in their structural strength and durability. Steel is renowned for its exceptional mechanical properties, such as high tensile strength, toughness, and resistance to wear and corrosion. These properties make it an ideal material for constructing heavy-duty machinery capable of withstanding the demanding conditions of construction sites. Steel coils are employed in the production of the structural components of construction equipment, such as chassis, frames, booms, buckets, and attachments. These components need to be sturdy and able to endure heavy loads, impacts, and continuous use. Steel coils provide the necessary strength and reliability to ensure the long-lasting performance of construction equipment. Moreover, steel coils are also used to manufacture specialized parts and accessories for construction machinery. These include hydraulic systems, gears, shafts, bearings, and fasteners. These components are essential for the proper functioning and efficiency of construction equipment, and steel coils provide the high-quality material required for their production. In addition to their mechanical properties, steel coils also contribute to the construction equipment industry through their versatility and customization options. Steel can be easily shaped, cut, welded, and formed into various sizes and shapes, allowing manufacturers to create equipment with specific designs and functionalities tailored to meet the diverse needs of construction projects. Overall, steel coils are indispensable in the construction equipment industry as they serve as the foundation for robust and reliable machinery. Their strength, durability, and versatility make them an essential raw material for manufacturing construction equipment that can withstand the challenges of construction sites and ensure the safety and efficiency of construction projects.

- Q: What are the common transportation defects in steel coils?

- There are several common transportation defects that can occur in steel coils. One of the most common is coil damage caused by improper handling or securing during transportation. This can result in dents, scratches, or even tears in the steel. Another common defect is coil edge damage, which can occur if the coils are not properly protected or if they rub against each other during transit. This can lead to deformation or even breakage of the coil edges. Additionally, coil shifting is another common defect, which happens when the coils are not properly secured or braced, causing them to move and shift during transportation. This can result in misalignment or damage to the coils. Finally, coil corrosion is a common defect that can occur if the coils are exposed to moisture or other corrosive elements during transportation. This can lead to rust and deterioration of the steel. Overall, proper handling, securing, and protection measures are crucial in order to prevent these common transportation defects in steel coils.

- Q: i heard steel type is good and i don't have any i have defeated all the trainers up to the icicle badge (i have got the icicle badge but not the one after) where can i get one?

- you can get a steelix at the cave just before the elite four. but if you have wifi, you can trade for one.

- Q: Steel, Sturm, and Kitiara are in a series called the Dragonlance Chronicles.

- Steel Brightblade was conceived when Kitiara and Sturm traveled together five years prior to the War of the Lance. Steel was then born at a woman named Sara Dunstan's house outside Palanthas. Kitiara let Sara raise him and when Sturm died Sara and Steel moved into the city of Palanthas. It's better explained in Second Generation by Margaret Weis and Tracy Hickman. Oh and I don't think the series is over commercialized I think that they could have done more with the original characters and the new characters. I'm also looking forward to the movie when it comes out next Autumn.

Send your message to us

Hot-Dip Galvanized Steel Coil Best Quality with Beautiful Surface

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords