Horizontal Multistage Booster Water Pump for Boiler Feed

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

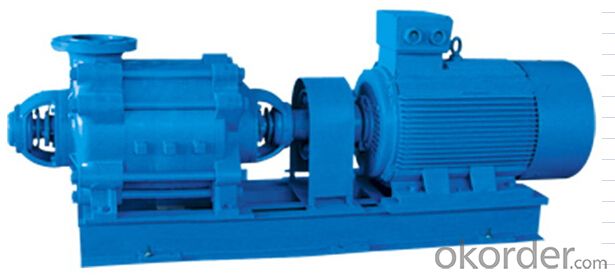

Horizontal Multistage Booster Water Pump for Boiler Feed

1.Structure of Horizontal Multistage Booster Water Pump for Boiler Feed

The high presuure boiler feed multistage water pump is a horizontal multistage centrifugal pump and suitable for transporting pure water,both ends of it are supported,the casing portion is a senctional form,it is connected and actuated by motor via a resilient clutch.From the driven direction,the pump rotated direction is clockwise.

2.Main Features of Horizontal Multistage Booster Water Pump for Boiler Feed

• High Effiency

•Low noise

•Long life, OEM and ODM are welcomed.

3.Horizontal Multistage Booster Water Pump for Boiler Feed Images

4.Horizontal Multistage Booster Water Pump for Boiler Feed Specification

Material |

Cast iron and as customer's request |

Temperature |

Less than 150°C |

Flow rate | 3.75-300m3/h |

Head | 75-1000m |

Medium temperature | 0 ~170°C |

Operation pressure | ≤40 bars |

5.FAQ

①What is the applications?

Power Station,Industry Water Supply

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance. Normally, We have 1 year warranty.

- Q: What is the Rhodes pump?

- Best answerRoots vacuum pump (referred to as: Roots pump) refers to the pump is equipped with two opposite direction of synchronous rotation of the leaf rotor, rotor, rotor and pump housing between the walls of a small gap and no contact with a variable capacity vacuum pump.Roots vacuum pumps have been tested for long time in the fields of petroleum, chemical, plastic, pesticide, steam turbine rotor dynamic balance and aerospace simulation, so it should be popularized and applied in china. It is also widely used in petroleum, chemical, metallurgical, textile and other industries. Vacuum pump fittings are used for noise control of vacuum pumps, vacuum pump silencers.

- Q: Operating procedures for measuring pumps

- First, preparation and inspection before starting1. Check to make sure that the drain line is equipped with a safety valve with the correct set pressure.2. Check the screws for the liquid end parts.

- Q: What is the pump delivery? What's the difference between years and years?

- 1) integer integer: ~ batch. Sell ~.2) buy in bulk: ~ goods. Sell now.The exchange is, according to the duration of the contract delivery insurance premium, payment is generally in common, 5 years of insurance you every year that time, continuous call five years; general single sex 5 years or even 10 years of premium.Furthermore, the insurance premium is good or good pay period, if a single rate from the point of view, to make cheaper than single period, but considering the one-time payment of the interest cost of funds and the opportunity cost, there is no difference. While the single cross ratio advantage is mainly reflected in its flexibility. First of all, additional premium may be added to the premium. At present, additional risks can only be covered if the main risks and principal risks are covered during the payment period. The single way to buy insurance, even in the primary insurance protection period will no longer be able to purchase additional insurance new; secondly, to pay the premium can enjoy a premium waiver. If the insured in full payment period has not yet had the danger, not pay part of the premium would be exempt from the Qing dynasty. For child insurance, the premium waiver is more advantageous. If parents unfortunate accidents or illness, resulting in death or one or two, three disabled or suffering from severe illness, the insurance company will be exempted after the premium, the insurance contract shall continue to be valid; finally, to pay the premium or additional premium amount can be changed. The policy holder may adjust his insurance plan according to the change in his economic strength. In contrast, single premium has the advantage of a one-time payment more convenient.

- Q: What is the function of a submersible pump?Do you have any knowledge about submersible pumps?.

- Submersible pumpThe submersible pump is composed of a control cabinet, submersible cables, water pipes, submersible pumps and submersible motors.Submersible pump main application and scope of applicationIncluding mine rescue, construction, drainage, agricultural irrigation and drainage, industrial water recycling, urban and rural residents cited water supply, and even rescue, disaster relief and so on.Classification of submersible pumpsAs far as media is concerned, submersible pumps can be broadly divided into three categories: clean water submersible pumps, sewage submersible pumps, sea water submersible pumps (corrosive).

- Q: Water pump does not produce water, what are the reasons?

- The reason why centrifugal pump does not produce water:1. pump inlet or sink, water tank water shortage.2. water pump pipe blocked or valve not open.

- Q: How can I buy a pump?

- 2, must meet the characteristics of the media requirementsFor the delivery of flammable, explosive, toxic or valuable medium pump, requiring reliable sealing shaft or the use of non leakage pump, such as magnetic drive pumps (without shaft seal, using isolated magnetic indirect drive).For the transmission of corrosive medium pumps, convection components are required to use corrosion-resistant materials, such as fluorine plastic corrosion resistant pump.For conveying pumps containing solid particles, wear resistance materials shall be adopted in convection parts, and clean liquid shall be used for shaft seal when necessary.

- Q: Harm of air pump and pump

- Centrifugal pump situationEmpty pump is divided into two kinds, if there is no liquid, then it will cause the mechanical seal of the pump to overheat, wear and even die

- Q: When the water pump is started, why should it start when the outlet valve is closed? Thank you

- When the valve is closed, the flow of the pump is close to zero, the power of the pump is very small, which reduces the load that the motor starts to bear and has a protective effect on the motor. Therefore, the valve closed to start the pump.

- Q: What is the series of pumps? What is the difference between a unipolar and a multilevel? What is the meaning of each "first class"?

- You're talking about a centrifugal pump. His series says the number of slices of the impeller (excluding the wheel, that is, the wheel)

- Q: Attention should be paid to the use of pumps?

- To carefully check whether there is a crack impeller, impeller fixed in the bearings are loose, if there are cracks and loose, hungry phenomenon should be promptly repaired, if the pump impeller above the soil should also be cleaned

Send your message to us

Horizontal Multistage Booster Water Pump for Boiler Feed

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords