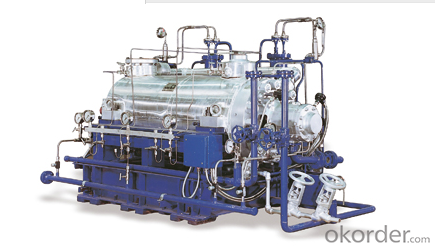

Horizontal, high-pressure barrel-type pump CHTR

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Design |

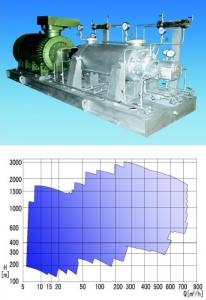

Overview of technical data

| Type of installation | Long- coupled |

| Type of bearing | Rolling element and plain bearings |

| Drive frequency | 50 Hz / 60 Hz |

| Maximum speed of rotation | 7. 000 1/min |

| Maximum flow rate | 1. 450 m³/h |

| Maximum discharge-side pressure | 400 bar |

| No. of impeller entries | Single / Double entry |

| Casing material | Duplex steel; Carbon steel;Chrome steel |

| Suction characteristics | Non- priming |

| Pull-out design | Yes |

| Other impeller types | Closed / Radial |

| Barrel casing | Yes |

| Pump set location | Dry installed |

| Type of suction casing | Annular casing |

| Max. permissible fluid temperature | 400 °C |

| Type of discharge casing | Annular casing |

| Main applications | Industry and process engineering; Energy;Oil / Gas |

| Type of installation | Stationary |

| Type of connection | Flange, weld ends |

| Type of lubrication | ( forced) oil lubrication |

| Type of drive | Electric motor, turbine |

| Installation position | Horizontal |

| Maximum suction pressure | 30 bar |

| Type of coupling | Direct; Gear;Variable speed coupling;Geared variable speed coupling |

| Shaft seal type | Mechanical seal |

| Maximum head | 4. 000,00 m |

| Type of stage casing | Stage casing with diffuser |

| Nozzle position | Variable |

| Casing partition | Radially split |

- Q: Rotary vacuum pump does not meet the requirements of vacuum, what are the reasons?

- 1) oil rotary vane vacuum pump is too low, no effect on the oil seal exhaust valve, rotary plug to refuel after large exhaust sound, and oil mist, that the level is too low, the gas can be eliminated.(2) the vacuum caused by the condensable steam pollution of oil should be changed, and new vacuum pump oil should be replaced.

- Q: How about the depreciation of vacuum pumps?

- (three) appliances, tools, furniture and so on related to the production and operation activities, for 5 years;(four) aircraft, trains, ships and other means of transport for 4 years;

- Q: What is the minimum continuous flow of a pump?

- The minimum continuous steady flow can be obtained by test and, in general, the pump supplier will indicate(2) minimum continuous heat limited flow (.API) provides minimum continuous heat limit flow, which means the minimum continuous flow that the pump can maintain and that its operation is not impaired by the temperature rise of the liquid being pumpedMinimum continuous heat limited flow can be calculatedIn the formula, the Pe amount of the fixed axis power is.KW;P pump medium density, kg / m3;

- Q: Is the diaphragm pump and the drain pump one?

- First of all, there's something wrong with your concept.Diaphragm pump is in accordance with the way the pump classification, drain pump is in accordance with the use of pumps classification.

- Q: What is the pump, how to classify, mainly used in where?

- 1. vane pumpThe impeller pump is driven by the impeller to rotate the liquid at high speed and transfer mechanical energy to the transported liquidAccording to the pump impeller and runner structure characteristics can be divided into different:1) centrifugal pump2) axial flow pump3) mixed flow pump4) vortex pumps3. jet pumpA high velocity jet produced by a working fluid is used to eject the fluid, and then the energy of the ejected fluid is increased by momentum exchange

- Q: What does centrifugal pump mean horizontally?

- Centrifugal pump horizontal opening meaning: pump shell and pump body along the pump blade horizontal central line is divided into the upper and lower halves, so that the maintenance of pump leaves when the pump top cover can be separated from the pump and bearing as a whole. No need to remove the pipe.

- Q: What is the working pressure of the hydraulic pump in the hydraulic transmission system?

- The choice of pressure depends on the size of the load and the type of equipment. Consideration shall also be given to the assembly space, the economic conditions and the availability of components for the actuators.In the case of a certain load, low working pressure, is bound to increase the structure size of the actuator on some devices, the size must be limited, from the perspective of material consumption is not the economy; on the other hand, the pressure to choose too large, the pump, cylinder, valve and other components of the material, sealing and manufacturing accuracy requirements very high, must raise the cost of equipment.

- Q: Is the sewage pump the same as the mud pump?

- Sewage pump is mainly used for industrial wastewater treatment, sewage treatment, environmental protection has played a big role. Among them, the sewage pump is also a sewage pump with cutting wheel, such sewage pump can be chopped dirt, and then extract the sewage clean.

- Q: How can I buy a pump?

- 2, must meet the characteristics of the media requirementsFor the delivery of flammable, explosive, toxic or valuable medium pump, requiring reliable sealing shaft or the use of non leakage pump, such as magnetic drive pumps (without shaft seal, using isolated magnetic indirect drive).For the transmission of corrosive medium pumps, convection components are required to use corrosion-resistant materials, such as fluorine plastic corrosion resistant pump.For conveying pumps containing solid particles, wear resistance materials shall be adopted in convection parts, and clean liquid shall be used for shaft seal when necessary.

- Q: What is a vacuum pump for?

- Aquaculture, screen printing machine, photographic plate machine, injection molding machine, automatic feeding machine, paper transport...

Send your message to us

Horizontal, high-pressure barrel-type pump CHTR

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords