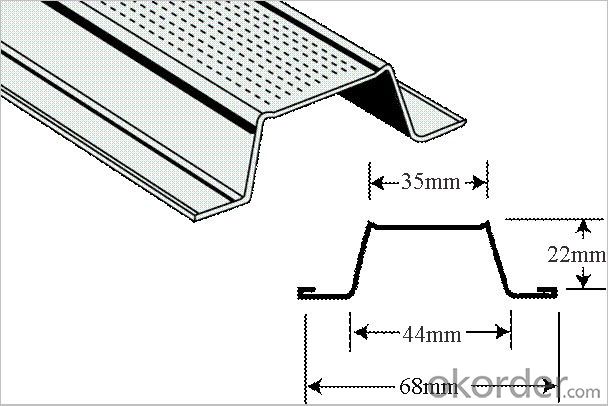

Ceiling Profile Furring Channel System

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Interior partition wall or veneering wall of hotels, theaters, emporiums, factories, office, house, airplane-terminal buildings, bus stations, waiting lounge, etc.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The partition of the bathroom and other wet condition building.

4.Indoor partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1.Light,good strength,cauterization resistance and water resistance;

2.Matching magnesium fire-proof board,gypsum board,and many other wall and ceiling board;

3.Moisture -proof,shock-resistance,high-effecient,environmentally-friendly and so on;

4.Easy and fast for installation,time-saving;

5.prompt delivery,high quality,competitive price and complete sets of style;

6.We can supply you the products based on your specific requirements;

Main Product Features:

metal drywall system galvanized steel profile c channel

Our drywall studs are made of galvanized steel sheet with good rust-proof function. The thickness is strictly according to the international demand.

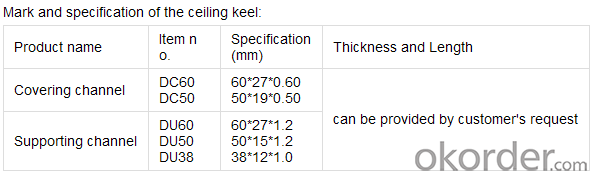

Product Specifications:

FAQ:

1:.How can I get your prompt quotation?

A: we can give you reply with quotation quickly if you kindly send the inquiry with specification.

2.What's the MOQ of the order?

No limit, we can offer the best suggestions and solutions according to your condition.

3. Which payment terms can you accept?

T/T,LC,Western Union,moneygram are available for us.

4. After an order is placed, when to deliver?

15-25days after confirming the order.

5. Does your company accept customization?

We accept OEM service.

Images:

- Q: Toilet integrated ceiling with good or good light steel keel good

- Of course the light steel keel is good. Wood keel gradually not used in the bathroom, the ceiling is not ventilated, a long time will be wet moldy. Reminded one, many brands of multi-grade ceiling, to their own to compare the choice of different stores.

- Q: What kind of material is better for some kind of ceiling, such as wood keel, light steel keel, or

- After the line with the woodworking board to open about 200mm wide oval frame (upper and lower layers) and then use 200 * 400 (height) of the wood plate around the oval to do the upper and lower layers of the two oval connected inside and then sealed 5mm board plate Hang up to shape out (drawing very good description of the painting really can not say you do not know clearly)

- Q: 38 light steel keel standard thickness is how much? Built-in 38 light steel dragon thickness to achieve how much to meet the requirements?

- 38 keel of the national standard thickness is 0.8mm. Positive and negative tolerances are generally 0.02-0.03mm The width is 38mm. Should look for light steel keel information point of view. You do not seem to understand it at all. Light steel keel called 38.50.75.100 .. The The Is their width. GB height is 10mm. Length is customizable. Generally 3m and 4m. In addition, the minimum standard of the ceiling keel should be 50 of the main keel. If it is to do 600 * 600 decorative ceiling. 38 GB can also be. Do the ordinary gypsum board ceiling 38 models are also insufficient. Affect the quality of the project.

- Q: Light steel keel ceiling cad chart

- There is a special light steel keel construction of the chart to sell, you can buy a set, only tens of dollars, inside the various forms of light steel keel ceiling, partitions have detailed construction techniques and regulatory requirements

- Q: Is the thickness of the light steel keel related to the height of the ceiling?

- Light steel keel selection with the weight of the ceiling, rather than height.

- Q: Ecological wood veneer gypsum board closed light steel keel ceiling decoration drawings so what is the meaning? How to understand

- The above is just speculation in accordance with the practice only, the designer belongs to the garbage family, did not see such a "note". It is recommended to consult the designer, be confirmed, so as to avoid mistakes.

- Q: Light steel keel ceiling need to pay attention to what issues?

- 1, ceiling uneven: small keel installed when the elevation is not allowed. Construction should pull the line, so that through the long keel by arch requirements, so that the elevation of accurate location. 2, wooden skeleton firm is not strong: large keel and hanging connection method, keel nail method should meet the design and construction requirements. 3, cover slab block gap is not straight, wide and inconsistent, construction should pay attention to plate specifications, block size, the installation location is correct. 4, pressure section, the pressure side is not tight, not straight: the construction should be the position of the line, cover the stone joints should be straight, pressure and sliver slate close to dense.

- Q: Light steel keel moisture-proof gypsum board ceiling which is the grass-roots which is the surface layer?

- Nice, smooth, neat positive

- Q: What is the keel of the aluminum veneer, or the angle welded frame?

- General buckle with a dedicated keel, keel for galvanized steel and paint steel, the standard length: 3000MM. Desheng Guangxing hope to help you.

- Q: Light steel keel how to do secondary ceiling

- Secondary ceiling local use of wood core board structure, hanging hanging wooden core board structure can do two ceiling. Any light steel keel ceiling of the multi-level ceiling and complex modeling, multi-use wood core board and light steel keel convergence.

Send your message to us

Ceiling Profile Furring Channel System

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches