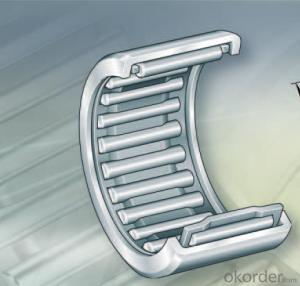

HK 1715 RS Needle Roller Bearing Drawn Cup Needle Roller Supply High Precision

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 900000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specifications:

Type: | Needle | Brand Name: | OEM | Bore Size: | 17 mm |

Outside Diameter: | 23 mm | Model Number: | HK 1715 RS | Precision Rating: | ABEC-1 |

Seals Type: | Open or Sealed | Number of Row: | Single Row | Place of Origin: | Jiangsu, China (Mainland) |

Material: | Chrome Steel | Lubrication: | Grease Lubrication | Package: | Plastic Bag and Box |

Equivalent: | HK 1715 RS |

Product Applications:

Needle roller bearings are mainly used in car engines, transmissions, compressors, cranes, etc.

Product Advantages:

1.Bearing Manufactory ( Have our own technical department)

2.High quality products (Long Life and low noise)

3.Well-daserved Reputation (Good Stock Guarantee)

4.Professional service ( Promptly shippment)

5.OEM Service,Sample is available

Packaging & Delivery

Packaging Details: | 1.industrial packing |

Delivery Detail: | in stock or 15-30days after P.O |

FAQ:

WHY CHOOSE US ???

1.More than 28 years export experience

2.Strict quality control

3.Delivery in time

4.OEM service are available with good price

5.Low MOQ

- Q: Hey guys my differential bearings are worn out, could they be the cause of the loud noise i hear whenever the car is turned on, when im at a stop, in neutral or in gear the noise doesnt go away, its not the muffler either or flex pipe as they were both replaced. Also whenever I let off the gaz pedal at rpms from 1500 to 3500 the car shakes back and forth, could it be because of worn out differential bearings? engine mounts were changed so i know its not that.Thanks in advance! Car is a nissan altima 2000 manual.

- IF IT STILL MAKES NOISE AT A DEAD STOP ITS NOT YOUR DIFF BEARINGS. how can they make noise if they are not moving? does the noise go away when the clutch peddal is pushed in or does the noise change sound when applying the clutch? if so then you got a throw out bearing gone bad. that is part of the clutch. if it shakes bad on take off then your flywheel is probably warped im guessing your clutch is wore out to. sounds like you need to see a technition and get it checked out. sounds like its clutch time

- Q: I have a racing bike. I've heard other racers using ceramic bearings in their wheels but not in their engines. Im based in Singapore btw.

- In certain places yes. What ever bike you are a racing in Singapore will not NEED ceramic bearings so I would not worry about it.

- Q: Hello, in my car hit another car from side to side, so damaged by right front wheel. The wheel was bent/cracked. Other than that it drove straight.Insurance is fixing the body work. After inspecting the car, they said the steering knuckle was loose/damaged.Is it possible for just a steering knuckle to get damaged, and not have to replace the wheel hub assemble/wheel bearings?

- confident going right into a pot hollow could reason your rim to get out of stability, usaully while in want of an alignment the motor vehicle pulls leftwards or rightwads yet from what you defined, this is maximum probable you like could get your wheels balanced, i anticipate your wheels are common wheels as damaging to alloys ,verify to verify if it nonetheless has a metallic bar clipped directly to the perimeters, it quite is what's used to stability common wheels.

- Q: Mechanic question? What are bearings?

- a bear's direction.

- Q: i am looking for new FKD bearings but i dont know which is better: FKD Abec 5 steel shield or abec 5 neoprene??

- Really no difference. Neoprene shields are a little easier to get out if you are going to clean or relube the bearings but you only have to take one out per bearing and only do it one time (since you don't reinstall the one you removed).

- Q: What bearings for inline skates are the best?

- A okorder ) because he is local and I can get them in person. He has several levels of ZeroDrag bearings that compare well with anything on the market. If your wheels use the 688 micro bearings (only in common use on some roller hockey wheels) your choices will be very limited. The 688's were popular on fitness and racing skates a few years ago but were found to not have the promised advantages and people complained that they were not as durable when subjected to outdoor conditions than the traditional 608 bearings. Most companies quit making 688 wheels and bearings, except for hockey.

- Q: Can I put it on skateboard bearings?

- You can, but it would be a bad idea. Bearings require lubricants based on their use. Grease is used where the temperature is high enough to liquify the grease to the proper viscosity. Also, if your skateboard has exposed ball bearings, the grease will collect and hold dirt, which will then act as a grinding compound and wear them out. If the bearing are sealed, no lubrication is necessary.

- Q: I have to replace my front wheel bearings on my truck.Can you point me in the right direction on how to tighten them down correctly after installation.How tight do i make the axle nut or anything that may have to do while i'm replacing them.Thanks.

- try getting a Haynes or a Chilton manual on the truck they have them in libraries and parts stores. also pay attention to how you take it off and how tight things are

- Q: What is the bearing capacity of needle bearing and copper sleeve?

- The bearing capacity of plain bearings with copper sleeve is large. However, the speed of the shaft has a certain requirement, the speed is too low, too high, can not establish oil film, will soon wear.

- Q: So, we have a map and we have to draw a cruises route on the map.The place where I started from to the line I drew is 15 degrees east from true north on a compass. The magnetic variation is 11 degrees east. Does that mean the compass bearing is 4 degrees east from north?I'm probably totally wrong. What's the true bearing? I'm confused :(

- I am confused too. You will get a good answer if you ask this in a different section e.g Homework or Mathematics.

Send your message to us

HK 1715 RS Needle Roller Bearing Drawn Cup Needle Roller Supply High Precision

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 900000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches