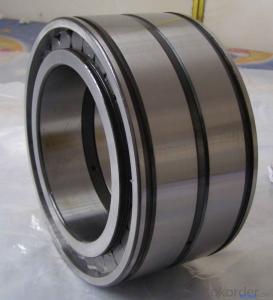

Stamping outer ring needle roller bearings

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stamping bearing also known as punching needle roller bearings or stamping outer ring needle roller bearings, needle roller bearings are used for supporting the design of radialload, reduce the friction between the rotating parts, stamping bearings with smaller cross section, can provide the load capacity of the largest in the smallest space, installed only when press in the bearing seat, very convenient, stamping needle bearing with full needleand frame with two design remain, both with stamping outer ring needle roller, as the outer raceway, full needle type stamping outer ring needle roller bearing has the largest number of needle, by stamping outer ring maintain, low cost, radial load carrying capacity is big, the standard to maintain a chip holding the steel frame comprises a frame type stamping outer ring needle roller bearings, needle roller guide for and maintain, which is characterized in that the running speed, the oil film retention capacity.

Introduction

Edit

Outer ring needle roller bearings is formed by thin steel plates, precision stamping, small structural space, and has a large load capacity. Applicable to the installation space is notrestricted and hole as raceway. And press in the bearing seat hole without further axialpositioning.

The main structural form:

Bearing code

Structure characteristics

HK

Keyhole stamping outer ring needle roller bearings

HK... RS

Keyhole stamping outer ring needle roller bearings with single sealing ring

HK... 2RS

Keyhole stamping outer ring needle roller bearings with double-sided sealing ring

BK

Keyhole stamping outer ring needle roller bearings

BK... RS

Sealing type stamping outer ring needle roller bearings with seals the side

F

Keyhole stamping outer ring needle roller bearings are filled

FY

Keyhole stamping outer ring needle roller bearings (oil filled limit)

MF

Sealing type stamping outer ring needle roller bearings are filled

MFY

Sealing type stamping outer ring needle roller bearings (oil filled limit)

The needle roller bearing without inner ring general. If you need to use the ring, you can select the IR inner ring.

DF stamping outer ring needle roller bearings for the two ends of the bearing pointsperforation (HK type) end and a bearing closed type (BK type). Compared with the keyholestamping outer ring needle roller bearing, one end sealed bearing as closed, suitable for shaft end, and can withstand the axial travel power small.

The 2 seal type stamping outer ring needle roller bearings

Edit

With the sealing ring to seal the sealing type stamping outer ring needle roller bearings, in general working conditions, can protect bearings from impurities from intruding and greaseleakage. Therefore, in the use temperature range of -20 DEG -120 DEG inside, the long term operation. If can timely supplement of suitable grease or short-term use, can be used for +130 degrees centigrade.

The sealing ring using synthetic rubber lip, good elasticity, and using the steel lining core,mechanical rigidity, in addition, the sealing ring gap to maintain axial guiding role.

- Q: plz answer if you have a skateboard and understand the difference

- z bearings. first clean them with goo be gone and then denature alcohal in a container you can shake em up real good. before cleaning take shields off. finish with two drops of bones speed cream. or get bones red bearings since they don't have that heavy grease in them.

- Q: If i get new bearings for my 88 camaro with a 305 tbi, about how much will it cost and how long could it take?

- A good rebuilt motor already put together by a good company with a good warranty will cost you around $1,300 for your car.It would be worth it to get a rebuilt motor.

- Q: recently my grease ball abec 5 have rusted and it is time for new bearings. which ones should i get. i am looking to spendo no more than 35 bucks

- What bearings? ABEC 5 is just a bearing grade......dosent tell anybody anything other than you currently have ABEC grade 5 bearings. What size, What part do they go on, How many do you need?

- Q: i need cranlkshaft bearings for my 1985 kx 125

- either try OKorder or some vary rare places in california make OEM part that date back a little bit so you might want to check dirt bike magazine. But that may take some time.

- Q: can i use rubbing alcohol to clean my skateboard bearings?

- whan i clean my bearings i put them in rubbing alcohol and it seems just fine to me it does not rust them or anything like that or make them go slower

- Q: When u need wheel bearings will your tire come off?

- Yeah, I almost succeeded in losing a wheel this way. Drove it for 2 days after it started making noise, and by the end of the second day on my way home from the parts store, it set itself up a real nice roar. Pulled in the driveway with steering going all over the place... when I jacked the car up that wheel was so loose it felt like it had no lug nuts! Took it apart only to find out the only thing holding it together was the remnants of the bearing and a flat washer that goes behind the nut! The inner bearing race had actually welded itself to the spindle, but thankfully I was able to save and repair the spindle, so all I had to replace was just the bearings and races, along with new nut and washers. Never gonna let that happen again... so lucky that thing didn't go flying off and cause me or another driver to wreck.

- Q: Im paying $1,200 to replace rear differential bearings for a ?

- AS usual there is far more to this on the surface than might be as the differential bearings means this is to do with wear of the crown and pinion gears and the loading of the bearings this is a specialized job. it requires special knowledge and whilst doing this other bearings with in the differential need to be replaced hence the high cost so yes sometimes when the car is a newer model this is a cheaper option. but in cars of a certain age this repair is the only option so is the car really worth this expenditure.

- Q: I don't even know if the bearings are broken. The wheel is not spinning well and it feels like the bearings could be broken. How do i check if the bearings are broken? If they are broken, then how do i fix them or do i have to get new ones? If i do need to get new ones, then how do i know which ones to get? Or, do i just need to get a new hub? Which one would be the easiest. new hub, or try to fix/replace the bearings. By the way the bike is a BMX bike. specifically a Fit Tech 1. Thanks!

- It depends on what is actually wrong, and how bad it is. If there is a clicking sound coming from the hub as you spin the wheel, it could be a broken bearing. The clicking is caused by the remaining ball bearings rolling over parts of the broken one. Most cycles have cup and cone wheel bearings, but some later top end ones could have a cartridge bearing. If one or more of the ball bearings has broken, and the wheel hasn't been used much since it broke, then a new set of bearings could be fitted. The hub will need to be stripped, cleaned, checked for wear, and if there is no damage, re - built with the new bearings. If the wheel has been used for some time with a broken bearing, then the bearing surfaces in the hub may damaged, and it will probably be cheaper to replace the wheel, rather than fit a new hub. If in doubt, take the wheel to a reputable cycle store, and ask them to look at it, they should be able to advise you on the best solution.

- Q: What Deck Trucks and Bearings n shizz would u recccomend for a street skateboader?

- Deck - any brand (as long as its not walmart or others like that) 7.5 - 8 inches wide, 30 - 32 inches long Trucks - any brand that is the same size as your deck Wheels - any brand 49 - 53mm big Bearings - Bones Reds Griptape - any brand Hardware - any brand Shoes - any brand For decks I would recommend Mystery, Flip , or Baker. There are tons more, but these are my favorites. For trucks I have always rode on Ventures, but many people say Independents are the best. For wheels many people ride on Spitfires or Bones Wheels. For bearings ride Bones Reds. Cheap and good. For griptape, it depends. Mob Grip is the grippiest. I usually ride on Jessup grip. All hardware is the same. They all break eventually, just buy some cheap ones. Many people wear smaller shoes for skating because they say it is easier to control the board more. I wear 12's but when I skate I wear 10.5s. I would recommend DVS, Fallens, or Globes.

- Q: I recently made a trade with another airsofter and i found that the shell was missing some ball bearings and the spring was bent. where can I find a replacement for this. I live near carpendersville and there are very few airsoft stores around that i can get to. The shell just releases the gas once i fill to a certain point (like in .25 seconds)

- Madbull grenades use 4mm bearing balls. Most other brands use 3mm bearing balls. I have not been able to find any metric bearing balls in any big box or local hardware stores, and SAE bearing balls will not work. You can buy 4mm and 3mm steel bearing balls from McMaster-Carr online. When I only need a few 3mm bearing balls, I get them off eBay. Some RC car differentials use 3mm bearing balls, so you can get 10 for less than $3 shipped. The springs are a bit different from maker to maker. Ball point pen springs do not have enough tension to effectively keep the shell from misfiring in your gear. Your best bet will be to either bring the existing spring with you to match it at the hardware store, or bring the valve and plunger to test fit springs. (Do NOT bring the whole shell to the store. That would be very unwise.) Good luck, D

Send your message to us

Stamping outer ring needle roller bearings

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords