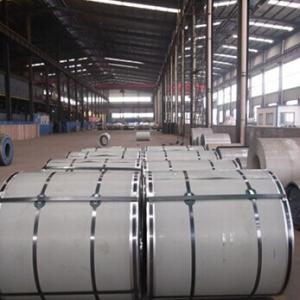

highqualityPre-painted steel coil for you

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Specification:

Thickness: 0.2-3.0mm

Width: 600-1500mm

Tolerance for thickness,width,flatness and so on conform to the requirements of JIS G3302 or ASTM A653M/924M

Coil ID can be either 508mm or 610mm, maximum coil OD is 2000mm

The speicfication of ASTM Such as A653m,A924 M and so on have been updated to the latest revisions

Zinc Coating Weight Symbol | AZ/Z 06 | AZ/Z 08 | AZ/Z 13 | AZ/Z 12 | AZ/Z 18 | AZ/Z 20 | AZ/Z 22 | AZ/Z 26 | AZ/Z 27 |

Zinc Coating Thickness (mm) | 0.013 | 0.017 | 0.021 | 0.026 | 0.034 | 0.040 | 0.043 | 0.049 | 0.054 |

Weight g/㎡ (both sides) | 90 | 120 | 125 | 183 | 244 | 285 | 305 | 345 | 381 |

ASTM A 525 | G-30 | G-40 | G-60 | G-90 | G-115 |

- Q: Can steel coils be coated with luminescent materials?

- Yes, steel coils can be coated with luminescent materials. This process involves applying a layer of luminescent material onto the surface of the steel coils, allowing them to emit light in the dark or under specific lighting conditions.

- Q: I need help! Please help, I'm in Chemistry, and me and my friend Lucy are making a presentation on steel and iron, so how is steel manufactured? Thank you. :D

- The steel consists of ( Iron ) and another matter... but the popular one is iron+carbon / iron+silver - When iron is smelted from its ore by commercial processes, it contains more carbon than is desirable. To become steel, it must be melted and reprocessed to reduce the carbon to the correct amount, at which point other elements can be added. This liquid is then continuously cast into long slabs or cast into ingots. Approximately 96% of steel is continuously cast, while only 4% is produced as cast steel ingots. The ingots are then heated in a soaking pit and hot rolled into slabs, blooms, or billets. Slabs are hot or cold rolled into sheet metal or plates. Billets are hot or cold rolled into bars, rods, and wire. Blooms are hot or cold rolled into structural steel, such as I-beams and rails. In modern foundries these processes often occur in one assembly line, with ore coming in and finished steel coming out. Sometimes after a steel's final rolling it is heat treated for strength, however this is relatively rare.

- Q: Or is it a coating that is applied? If so what types of steel? Or what types of coatings?

- No, usually they are just coated or galvanized. To make a steel that is truly more corrosion resistant raises it's cost quite markedly, where as coatings are pretty cheap. Almost all structural steel is just A36 mild steel (like 0.1% carbon, 0.05% Mn, and not much else). There are higher grades of structural steel, and bridges are made with truly more corrosion resistant carbon steels, but for a house it's just not the case.

- Q: What are the different types of steel coil storage methods?

- There are several types of steel coil storage methods, including stacking coils directly on the floor, using racks or shelves, utilizing coil cradles, employing coil saddles, and implementing coil cars or trucks for transportation and storage.

- Q: Have spent two days making a specialized knife out of 304 stainless steel, after throwing into a log it bent slightly arghhhh. Is it worth continuing to finish it off or start all over again with different kind of steel if so which kind should i use.

- Sorry okorder /... I hope that link works but as you can see you dont want to use 303.304.316,410,416,430 You can get away with 301 but would be best to use 440. It kind of sounds like your a home shop guy. It would be best for you to make a knife out of a1 or d2 tool steel. with these steels you can torch heat them to a red hot heat where a magnet will not stick to them. Then let them cool slowly in the air. After that you can temper in a oven around 400f. This will a very hard long lasting knife. Check OKorder for good steel prices. A1 and D2 are not stainless but they are the best for a home shop. If you go stainless you can buy preharden material but you will have to grind everything. You can also pay someone to harden your knife but dont plan on it being cheap.

- Q: hello, I am trying to figure out what wok to get and came across a website that offers many woks out of different materials. what is the best, or considered original (traditional)? I have a couple of cast iron pots and pans - too heavy, so I am assuming it will take some time for a cast iron wok to heat up. what about carbon steel and stainless steel? Thanks

- 1. Do not buy stainless Steel wok. Stainless steel is a poor conductor of heat. 2. Cast iron is traditional. It is heavy and takes long to heat and cool. You can get used to heating cooling, but weight can be a problem. I would not buy cast iron. 3. You may not believe this but carbon steel is also traditional and most widely used wok. Normally, a good wok is pounded out of high carbon steel thick stock. The pounding leaves thick bottom and gradually thinner walls. It is a good conductor of heat, easy to heat and cool, and light weight to mange taking off the heat when needed. I recommend buying high carbon steel wok

- Q: What are the environmental impacts of steel coil production?

- The environmental impacts of steel coil production include air and water pollution, deforestation, energy consumption, and greenhouse gas emissions. The production process involves the extraction of raw materials, such as iron ore and coal, which can lead to habitat destruction and soil erosion. Additionally, the high energy requirements and use of fossil fuels contribute to air pollution and greenhouse gas emissions, exacerbating climate change. The wastewater generated during production may contain harmful chemicals that can contaminate water sources and harm aquatic life. Overall, steel coil production has significant environmental implications that need to be addressed through sustainable practices and innovative technologies.

- Q: I know that steel wool is coated with... something... that protects it from rusting. I need to know what that is, and how to get it off.

- spun steel fibers have a microscopic coating of oil to prevent them from rusting. Rusting steel wool wouldn't sell very well. I would think that removing this oil could be accomplished with any good degreaser, like brake cleaner or the like. However, I've never tried this before. In science class they perform experiments by removing the oil with vinegar. After wringing out the steel wool pad, it is wrapped around a thermometer and placed in a sealed jar. After a few minutes the temperature rises because of the chemical reaction that takes place when four atoms of iron react with three atoms of oxygen and create two atoms of iron oxide - RUST! You can unwittingly recreate this experiment by using steel wool in the process of removing one or more layers of finish from a piece of furniture Hope this helps

- Q: What are the different types of steel coil finishing processes?

- Enhancing the appearance and properties of steel coils involves employing various steel coil finishing processes. Among the commonly used processes are: 1. Hot-dip galvanizing: Immersing the steel coil in molten zinc forms a protective layer on its surface, enhancing corrosion resistance and providing a visually pleasing finish. 2. Cold rolling: Passing the steel coil through rollers at room temperature reduces thickness and improves surface finish. This process can yield finishes ranging from matte to highly polished. 3. Electro-galvanizing: A thin layer of zinc is electrolytically deposited onto the steel coil's surface. This method is suitable for applications requiring a thinner zinc coating and a more uniform finish. 4. Pickling and oiling: Treating the steel coil with an acid solution removes scale and impurities, resulting in a clean and smooth surface. Coating the coil with oil prevents rust during storage and transportation. 5. Powder coating: Dry powder is applied to the steel coil and cured under heat to form a durable and attractive finish. This method allows for a wide range of colors and finishes. 6. Paint coating: Similar to powder coating, liquid paint is applied to the steel coil's surface. This process offers decorative finishes and protection against corrosion and environmental factors. These examples represent only a few of the available steel coil finishing processes. The choice of method depends on specific application requirements, including desired appearance, corrosion resistance, and durability.

- Q: i bought an airsoft gun and it said steel recievers on it im not sure what that is

- Basically okorder / And so on and so on. Contrary to what the first answerer said, steel receivers aren't that bad. They do give a bit of heft but they are quite durable, give a realistic feel, and don't break when you land on them by accident.

Send your message to us

highqualityPre-painted steel coil for you

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords