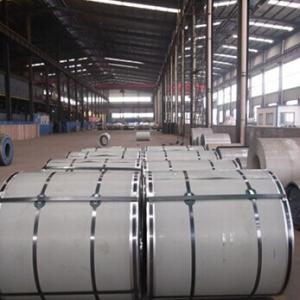

Pre-painted steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Specification:

Thickness: 0.2-3.0mm

Width: 600-1500mm

Tolerance for thickness,width,flatness and so on conform to the requirements of JIS G3302 or ASTM A653M/924M

Coil ID can be either 508mm or 610mm, maximum coil OD is 2000mm

The speicfication of ASTM Such as A653m,A924 M and so on have been updated to the latest revisions

Zinc Coating Weight Symbol | AZ/Z 06 | AZ/Z 08 | AZ/Z 13 | AZ/Z 12 | AZ/Z 18 | AZ/Z 20 | AZ/Z 22 | AZ/Z 26 | AZ/Z 27 |

Zinc Coating Thickness (mm) | 0.013 | 0.017 | 0.021 | 0.026 | 0.034 | 0.040 | 0.043 | 0.049 | 0.054 |

Weight g/㎡ (both sides) | 90 | 120 | 125 | 183 | 244 | 285 | 305 | 345 | 381 |

ASTM A 525 | G-30 |

| G-40 | G-60 |

| G-90 |

|

| G-115 |

- Q: How are steel coils used in the production of metal fixtures?

- Steel coils are used in the production of metal fixtures as they are often the starting point for manufacturing processes. These coils are unwound and cut into specific lengths, which are then shaped, bent, and welded to create various metal fixtures such as shelves, brackets, and frames. The steel coils provide a consistent and high-quality raw material that can be easily formed and manipulated to meet the desired specifications of the fixtures being produced.

- Q: Molton is formed at 2800 F. Thats a fact. Now jet fuel at its hottest is 1800. Where does the other 1000 degress come in? And it was found at the WTC 7 site. Was this hit by a plane? A simple fire COULD NOT produce molton. This is a fact. Molton is formed during controlled demoliton of a building since all the bombs in the buiding go off and its very very hot. The fact there was MOLTON at the site is shocking to some since it is IMPOSSIBLE for molton to form from jet feul alone. Impossible. It needed another source. Now the claim that I'll get is that it weakened the stell but then we would find weak steel not molton. Why do you seem to throw this off of your shoulder? Do you not want to belive it? I'm no jet fuel guy but I know you cannot make molton by using just jet fuel. This is really proof that 9/11 was an inside job.

- People who believed the buildings collapsed because of the planes are far far off. 1. Burning jet fuel CANNOT melt steel - FACT! 2. The twin towers were built to withstand a hit from a Boeing 707 - FACT 3. NORAD didn't respond - for the first time EVER! - FACT! 4. The pentagon has the most CCTV cameras than any other buildings in the world and they only release the tape which the plane is not visible, they also confiscated the tape from the store opposite which would have shown the plane - if it existed. State sponsored terrorism has been around for along tI'me, im surprised at how many people still believe the official story.

- Q: why does steel have a density range when other metals do not?

- Steel is not a pure element it is an alloy. Steel is primarily iron but it has many elements blended in that change it's density including carbon,silicon, nickel, chrome, etc. Aluminum and copper , magnesium and so forth can be the pure element or they can be alloys too. If they are alloys, then their densities vary also

- Q: Can steel coils be welded?

- Yes, steel coils can be welded. Welding is a widely used process for joining metal components, including steel coils.

- Q: What is steel made of? What are the elements other than iron?

- mainly steel made of Iron and carbon and treated in a proper process to become hard you can add some kind of other elements to get your desired proparty as Chromium,, nickle.. Cupper,, Berelyium,, Vanadium

- Q: How do steel coils contribute to the HVACR equipment industry?

- Steel coils play a crucial role in the HVACR (Heating, Ventilation, Air Conditioning, and Refrigeration) equipment industry by providing efficient heat transfer and ensuring the effective functioning of various HVACR systems. These coils are typically made of high-quality steel and are an integral component of equipment such as air conditioners, heat pumps, refrigerators, and boilers. One of the primary functions of steel coils in HVACR equipment is to facilitate heat transfer. These coils are designed to efficiently transfer heat between the refrigerant and the surrounding air or water, depending on the specific system. By utilizing steel coils with a large surface area and good thermal conductivity, HVACR equipment can effectively cool or heat a given space. This ensures optimal energy efficiency and reduces operating costs for both residential and commercial applications. In addition to heat transfer, steel coils also contribute to the overall durability and longevity of HVACR equipment. The steel used in these coils is typically corrosion-resistant, which helps prevent damage from moisture or other environmental factors. This reliability is essential in HVACR systems, as they are often subjected to harsh conditions and must operate continuously to maintain comfortable indoor environments. Moreover, steel coils are versatile and can be customized to meet the specific requirements of different HVACR applications. Manufacturers can vary the size, shape, and configuration of the coils to fit the available space and optimize performance. This flexibility allows for the efficient integration of steel coils into various HVACR equipment, ensuring they meet the specific heating and cooling needs of different environments. Overall, steel coils are indispensable in the HVACR equipment industry. They enable efficient heat transfer, enhance durability, and offer customization options, thereby ensuring the effective functioning and energy efficiency of HVACR systems. By incorporating high-quality steel coils into their products, manufacturers can provide reliable and long-lasting solutions for heating, ventilation, air conditioning, and refrigeration needs in both residential and commercial settings.

- Q: I was wondering what material most common motorcycle gas tanks are made out of? is it steel? stainless steel? aluminum? what are the advantages and disadvantages or each?

- Steel is the norm. Aluminum is lighter, but can be prone to cracking from vibration. It is seen more often in custom tanks, especially for custom cafe racers, Guzzis, Ducatis, Tritons, and the like. Dirt bikes use plastic tanks. Most after-market tanks for dual sports and adventure tourers are also made from plastic.

- Q: I Don't have a Oxy act. torch but can Get a Propane one. The finished part(s) are .375 x .550 x .185

- *Hardening: okorder /... AISI 12L14 : Category :Steel Class :Carbon steel Type :Standard resulfurized and rephosphorized Common Names :Lead steel Designations: Germany: DIN 1.0718 Italy: UNI 9 SMnPb 23 Japan: JIS SUM 22 L , JIS SUM 24 L Sweden: SS 1914 United States: ASTM A108 , ASTM A29 , SAE J403 , SAE J412 , SAE J414 , UNS G12144 Composition : Element / Weight % C / 0.15 (max) Mn / 0.85-1.15 P / 0.04-0.09 S / 0.26-0.35 Pb / 0.15-0.35 Mechanical Properties : Properties / Conditions / T (°C) /Treatment Density (×1000 kg/m3) 7.7-8.03 / 25 Poisson's Ratio 0.27-0.30 /25 Elastic Modulus (GPa) 190-210 / 25 Tensile Strength (Mpa) 540 / 25 /cold drawn (round bar (19-38 mm)) Yield Strength (Mpa) /415 Elongation (%) /10 Reduction in Area (%) /35 Hardness (HB) 163 /25 /cold drawn (round bar (19-38 mm)) *Rod- 12L14 Case Hardened to Rockwell C 58-62 Case Depth .060 Sleeve - 12L14 Case Hardened to Rockwell C 58-62 Case Depth .060 Blade - 12L14 Case Hardened to Rockwell C 58-62 Case Depth .030 Quantity 5000 Rods: Weight per piece .8 ounce (Total 250 pounds) 5000 Sleeves: Weight per piece 1.8 ounce (Total 563 Pounds) 5000 Blades: Weight per piece .3 ounce (94 pounds) Total weight of RFQ 907 pounds 12L14 Steel.

- Q: I have an old classical guitar, which uses nylon strings. ive never really liked the sound produced by the nylon, so im curious if you can use a classical guitar with acoustic guitar steel strings. thanks!

- Everyone okorder /... The treble strings are steel, but are gauged so that they are at a lower tension than the treble strings on a western acoustic. The bass strings in Martin Silk Steel have a silk based core, and a metal wrap wire (just like in normal classical guitar strings), which again keeps the tension in the strings lower than its steel based cousins. The Martin Silk and Steel will give you a more western acoustic sound, but it won't be exactly the same as a western acoustic guitar.

- Q: What are the different methods of edge trimming for steel coils?

- There are several different methods of edge trimming for steel coils, including slitting, shearing, and laser cutting. Slitting involves cutting the coil into narrower strips using circular blades. Shearing involves cutting the edges of the coil using a straight blade. Laser cutting uses a high-powered laser to precisely trim the edges of the coil.

Send your message to us

Pre-painted steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords