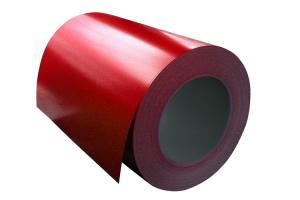

PRE-PAINTED GALVANIZED STEEL COIL WITH VERY HIGH QUALITY

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Painting steel is the product based on the metal sheet, of which surface is finally installed of the plastic film(PVC, PE) IN addition to being firstly covered with the coating and printed ink in. The coated layer of painting steel plate consists of chemical and filming layer, primer coated layer, pattern printed layer and surface coated layer. The top and back coating shall generally be the weatherproof paint, as well can be the application of the paint with special capabilities such as stain-resistant, self cleaning capability, high thermal resistance, antistatic capability, sterilizing capability, finger-print prevention and etc.

With GI(aluzinc) as base metal, after pretreatement(degrease and chemical treatment)and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc)steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

Available specification:

PAINTING STEEL | |

BASE MATERIAL | HDGI, ALUZINC,CR |

GRADE | SGCC, DX51D,ASTMA653,EN10142,S350GD |

THICKNESS | 0.17-1.0mm |

WIDTH | 600-1250mm |

ZINC COATING | 60-200g/㎡ |

PAINT | PE,PVDF,SMP,HDP |

COILED | 508mm |

COIL WEIGHT | 3-6mt |

We can supply customers' with different specifications of the highest quality and lowest price.

Sincerely welcome to contact us for the future details if any item interest you ,and we will make every effort to assure that your requirements will be satisfied ,and we hope to establish long-term business relations with you on the basis of the equality and mutual benefit.

We are waiting for your email.

- Q: What are the applications of steel coils?

- Steel coils have a wide range of applications across various industries, such as construction, automotive, appliances, and manufacturing. They are primarily used in the production of sheet metal, pipes, and tubes, as well as for manufacturing parts and components. Steel coils are also used in the fabrication of various structures, including buildings, bridges, and infrastructure projects. Additionally, they find use in the production of household appliances, vehicles, machinery, and other consumer goods.

- Q: i have a white spot on my stainless steel stove, its on the part behind the burners where the oven controls are, does anyone know what it may be and how to remove it. i have tried soap and water and stainless steel cleaner but neither worked. thanks!

- Barkeeper's Friend is the bomb for a metal and fiberglass cleaner, if it can be removed, it will remove it. I have no clue what it is thats on there.

- Q: What are the dimensions of a typical steel coil?

- The dimensions of a typical steel coil can vary depending on its intended use and manufacturing specifications. However, common dimensions for a steel coil typically range from 0.15 to 3.5 millimeters in thickness, and 600 to 2,000 millimeters in width. The inner diameter of the coil can be around 508 to 610 millimeters, and the maximum outer diameter can be up to 2,000 millimeters.

- Q: Explain how you could make plastic sink and steel float?

- plastic can be denser than water. Make it a brick and it sinks. Ships float because they are mostly air - surrounded by steel.

- Q: I have a need to connect various stainless steel tubes and fitting together and was wondering how to do it. I know a TIG welder is an option but have heard rumors that there is a way to solder it in much the same way you affix copper pipe. Perhaps with higher heat and different flux. I need step by step and maybe suppliers of the materials. Thanks in advance and please I do not need the call a plumber answers as I've gotten in the past

- Soft Soldering All grades of stainless steel can be soldered with lead-tin soft solder. Leaded solders should not be used when the product being soldered is used for food processing, serving or transport. Soldered joints are relatively weak compared to the strength of the steel, so this method should not be used where the mechanical strength is dependent upon the soldered joint. Strength can be added if the edges are first lock-seamed, spot welded or riveted. In general, welding is always preferable to soldering. Recommended procedure for soldering: · 1. The steel surfaces must be clean and free of oxidation. · 2. A rough surface improves adherence of the solder, so roughening with grinding wheel, file or coarse abrasive paper is recommended. · 3. Use a phosphoric acid based flux. Hydrochloric acid based fluxes require neutralising after soldering as any remnant traces will be highly corrosive to the steel. Hydrochloric acid based fluxes are not recommended for soldering of stainless steels. · 4. Flux should be applied with a brush, to only the area being soldered. · 5. A large, hot iron is recommended. Use the same temperature as for carbon steel, but a longer time will be required because of stainless steel's low thermal conductivity. · 6. Any type of solder can be used, but at least 50% tin is recommended. Solder with 60-70% tin and 30-40% lead has a better colour match and greater strength.

- Q: I have a 03 jeep wrangler and looking to upgrade to black wheels. I was wondering if the difference between steel and alloy wheels is worth paying double.

- steel is steel is steel- they will always be heavy you would have to weigh them to find out--NOW if you are going to alloy wheels they are typically aluminum and yes they are lighter -this is good because it lightens your un-sprung weight and is less harmful to your suspension-good for your auto

- Q: How are steel coils inspected for straightness?

- Steel coils are typically inspected for straightness using various methods such as visual inspection, laser measurement, or by passing the coils through straightening equipment.

- Q: How are steel coils used in the production of electrical switches?

- Steel coils are used in the production of electrical switches as they act as the core of the electromagnetic system. When an electric current passes through the coil, it creates a magnetic field which attracts or repels a movable metal component, allowing the switch to open or close. This mechanism is crucial for controlling the flow of electricity in various electrical devices and systems.

- Q: I need details for steel column splices welded or bolted. References or autocad blocks will be very useful. Thank you very much!

- Boy oh boy, that request would open you up to a bunch of different types of files and drawings. There are so many different ways to make a column splice for structural steels. And they all would depend greatly on the loads that the joint will be subject too. You need to find a copy of the Manual of Steel Construction Ninth edition (or newer if its out, mine is the ninth), from the AISC 'American Institute of Steel Construction. This book will show you quite a few different connection options, welded and bolted. You will need to make drawings from the dimensions and details you see in the book. One other thing, you might try to find a manual for steel detailing, the seventh edition of the above book had a section to show detailing dimensions for different steel elements, dependant on the size and shape of the member itself.

- Q: I have some steel wool and a charged 9V Battery, when I connect 2 wires to the battery, then touch the wool with the ends of the wires the wool instantly starts burning, but when I connect 2 wires to the piece of steel wool (a new piece not same one of course) and touch the battery with the ends of the wire nothing happens (see image...)

- What's happening in the first case is that the initial contact of the wire to the steel wool is not very good and there is a high resistance as the touch is made and there is probably a slight spark that starts the steel wool burning. Now it is even harder to make good contact and the process continues. In the second case there is initially a good contact to the steel wool and there is no spark when the circuit is completed at the battery. It would be difficult to cause the heating and the spark at a distance unless you had a way to remotely cause the wire to lightly touch the steel wool. A gas lighter which uses a flint to create a spark is good for igniting a gas burner which will continue to burn by itself, but probably wouldn't cause the steel wool to burn without the energy coming from the battery to keep it going. Steel wool WILL continue to burn if it's in a pure oxygen atmosphere. You might try hooking the battery up to the steel wool as in the second case and using a spark lighter to start some burning close to one of the wire connections to see if the extra battery power might keep the burning going.

Send your message to us

PRE-PAINTED GALVANIZED STEEL COIL WITH VERY HIGH QUALITY

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords