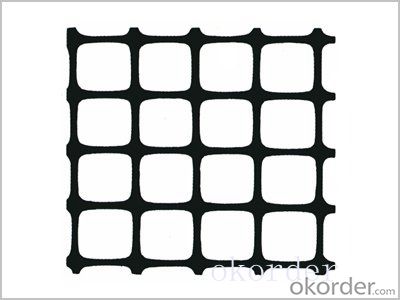

High Tensile Strength Steel Plastic Geogrids for Slope Erosion Geocells Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Type:

Geogrids

Place of Origin:

Anhui, China (Mainland)

Brand Name:

CMAX

Model Number:

Biaxial

Product Introduction

The Steel plastic composite geogrid is by the high tensile steel wire, after the special handing, with the polyethylene(P. E), and increase other assistants, though squeezes out causes it excel to become the mult-skill anti-to pull the banding, and the surface has the rough embossing, for excel in reinforcement earthwork belt. From this as soon as the single belt, after vertical, according to decides the spacing knitting horizontally or clamps gathers the arrangement, uses the ultrasonic welding to molding.

The Steel plastic composite geogrid is by the high tensile steel wire, after the special handing, with the polyethylene(P. E), and increase other assistants, though squeezes out causes it excel to become the mult-skill anti-to pull the banding, and the surface has the rough embossing, for excel in reinforcement earthwork belt. From this as soon as the single belt, after vertical, according to decides the spacing knitting horizontally or clamps gathers the arrangement, uses the ultrasonic welding to molding.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Are there any limitations or disadvantages of using geogrids?

- Yes, there are some limitations and disadvantages of using geogrids. Firstly, geogrids are not suitable for all types of soil conditions and may not be effective in areas with highly cohesive or expansive soils. Secondly, geogrids have limited tensile strength and may not be able to withstand heavy loads or extreme environmental conditions. Additionally, geogrids require proper installation techniques for optimal performance, which may increase the overall project cost. Lastly, regular maintenance and inspection are necessary to ensure the long-term effectiveness of geogrids, adding to the maintenance expenses.

- Q: How do geogrids enhance the performance of geocells?

- Geogrids enhance the performance of geocells by providing additional stability and reinforcement. They are placed within the geocell structure to increase load-bearing capacity, prevent lateral spreading, and improve overall structural integrity. This combination of geogrids and geocells creates a stronger and more durable foundation for various applications such as soil stabilization, erosion control, and slope protection.

- Q: Can geogrids be used in geotechnical engineering?

- Yes, geogrids can be used in geotechnical engineering. They are often used as reinforcement materials in soil structures to improve their strength, stability, and load-bearing capacity. Geogrids are particularly effective in applications such as retaining walls, embankments, slopes, and pavements. They provide reinforcement to the soil, preventing lateral spreading, reducing settlement, and increasing overall performance of the geotechnical structures.

- Q: Are geogrids resistant to freeze-thaw cycles?

- Yes, geogrids are generally resistant to freeze-thaw cycles. Their material composition and design allow them to withstand the expansion and contraction caused by freezing and thawing temperatures without significant damage. This resistance makes geogrids suitable for various applications in cold climates where freeze-thaw cycles are common.

- Q: What are the applications of geogrids in civil engineering?

- Geogrids have numerous applications in civil engineering. They are commonly used for soil stabilization, especially in areas with weak or unstable soils. Geogrids provide reinforcement and improve the load-bearing capacity of the soil, making them ideal for constructing roads, embankments, and retaining walls. They also prevent soil erosion and help in the construction of reinforced slopes. Additionally, geogrids are utilized in the reinforcement of foundations, landfills, and land reclamation projects. Overall, geogrids play a crucial role in enhancing the durability and stability of civil engineering structures.

- Q: Can geogrids be used in floating parking lot construction?

- Yes, geogrids can be used in floating parking lot construction. Geogrids are commonly used in various civil engineering applications, including building parking lots. They help reinforce the ground and distribute loads, making them ideal for stabilizing the soil beneath floating parking lots.

- Q: Can geogrids be used in stormwater management applications?

- Yes, geogrids can be used in stormwater management applications. Geogrids are often used to reinforce and stabilize soil in various construction projects, including stormwater management systems. They help to improve the strength and stability of the soil, allowing it to better withstand the forces and pressures exerted by stormwater. Additionally, geogrids can also enhance the performance of stormwater management structures by preventing soil erosion and promoting water infiltration. Overall, geogrids are a valuable tool in stormwater management applications.

- Q: How do geogrids improve the stability of steep slopes?

- Geogrids improve the stability of steep slopes by providing reinforcement and support to the soil through their tensile strength. When installed horizontally or at an angle within the soil, geogrids help distribute the load and reduce the potential for slope failure by increasing the soil's resistance to sliding and erosion. Additionally, they enhance the overall stability by preventing excessive soil movement and promoting better compaction, thereby increasing the slope's shear resistance.

- Q: What are the different types of geogrids available?

- There are several different types of geogrids available, including uniaxial geogrids, biaxial geogrids, and triaxial geogrids. Uniaxial geogrids have strength in one primary direction and are often used for soil reinforcement and slope stabilization. Biaxial geogrids have strength in two directions and are commonly used for pavement stabilization and ground reinforcement. Triaxial geogrids have strength in three directions and are typically used for heavy-duty applications such as retaining walls and embankments.

- Q: Are geogrids resistant to chemical degradation?

- Yes, geogrids are typically resistant to chemical degradation. They are designed to withstand exposure to various chemicals commonly found in soil and water, making them durable and suitable for long-term applications in civil engineering and construction projects.

Send your message to us

High Tensile Strength Steel Plastic Geogrids for Slope Erosion Geocells Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords