High Strength Mooring Rope,polyester, High Molecular Polythylene (UHMWPE).

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 pc

- Supply Capability:

- 0 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Mooring Rope

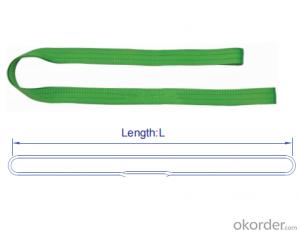

Production Scope: The structure of mooring rope can be divided into 3-strand, 6-strand, 8-strand and 12-strand. The raw material includes: polypropylene, polyester, nylon, High Molecular Polythylene (UHMWPE), aramid fibre and synthetic fibre. Diameter scope: Φ6mm ~ Φ140mm are available.

Characteristics of mooring rope: high tensile, low stretch, anti-friction, corrosion resistance, soft and smooth, easyto operate, etc. Mooring ropes are mainly used in shipping equipment, fishing industry, port operation, electric construction, oil exploration, national defense and sports goods, etc.

Achievements in scientific research:

In 1997, we drafted out the industrial standard for textile slings together with Beijing Hoisting Machinery Institute: JB/T8521-1997, which makes historic progress for the Chinese textile sling industry.

In 2007, we revised JB/T8521.1-2007 “Textile Sling – Safety - Part 1: Common use webbing sling” and JB/T 8521.2-2007 “Textile Sling - Safety - Part 2: Common use round sling”.

In 2009, we edited GB/T 23914.2-2009 “Road vehicle mounted fixtures – Safety – part 2: Synthetic ratchet strap assemblies”, participated in writing TB/T 3123.11-2009 “Rescue devices for railway accidents - part 11: high-performance textile sling”.

In 2014, we participated in writing GB/T 30667-2014 “Polyester and polyolefin dual Fiber rope” and GB/T 30668-2014 “8 strands, 12 strands and multiflament braided Ultra high molecular weight polyethylene fiber rope”.

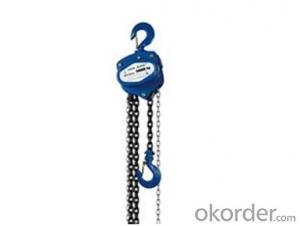

- Q: Do cranes have the same wire ropes, slings, slings and cables?

- A steel wire rope is a common wire rope, and a sling is a special tool for lifting some goods. The sling is a sling tool made of wire ropes

- Q: What are the dangerous sections of the crane hook?

- ) C -C section of the section is the thinnest part of the hook column in a sling tension, have pulled off the trend. Here the maximum tensile stress, it is also dangerous section.

- Q: 20 tons sling rope, steel wire or chain?

- The main - phosphating coating steel wire rope, galvanized steel wire, stainless steel wire rope and coated steel wire rope wire rope varieties, for reference only

- Q: Which brand is better for imported rigging?

- Germany's mechanical products are better, quality world-class, CarlStahl sling rigging is Germany's old brand.

- Q: Requirements and matters needing attention in hoisting

- We often encounter equipment installation, transport and installation work, whether the derrick is lifting or hoisting machinery should pay attention to the following points: (1) the indigenous construction equipment for handling mobile rolling method, the rolling rod thickness should be consistent, should buetow annual row width is 50cm long, no gloves in rollers. While loading and unloading piping shall not be greater than 20 degrees slope, raceway erection should be smooth, solid, joints staggered, the rolling speed is not too fast, when necessary to use ropes.(2) in the course of installation, if problems are found, measures should be taken in time, and then continue to be hoisted after treatment.(3) large tower equipment for hoisting derrick, hoists joint operation, the hoist hoisting speed must be roughly the same, to ensure that the tower body of each suspension force roughly uniform, avoid the tower stress uneven deformation.

- Q: They are used for slings, ropes, chains, suspenders, hand hoists, right?

- The use of atmospheric environment, patented technology to produce manganese phosphating coating of steel wire rope has the longest lifespan, manganese phosphating coating can greatly improve the wear resistance and corrosion resistance of the steel wire surface, the fatigue life of the phosphating coating steel wire rope is 3-4 times of smooth wire rope, with the research on the wear resistance of the phosphating liquid, as well as to further improve the possibility of. According to the current market price of the phosphating coating steel wire rope, phosphating coating steel wire rope daily use cost is just plain steel wire rope about thirty percent of phosphating coating steel wire rope is a substitute for plain steel wire rope upgrade, for reference only.

- Q: The wire rope lock can hang a lot of things

- The crane used in atmospheric environment, preferably manganese phosphide coating, steel wire rope, heavy corrosive environment, preferred hot-dip galvanized double phosphating steel wire rope, priority wire rope in sea water. Please note that at the time of purchase, in the purchase invoice must indicate the name of wire rope, such as phosphate coated wire rope or 316 stainless steel wire rope, to protect their legitimate rights and interests, in addition, patent products are generally in the rope on the outer packing of a patent spraying label, warranty should be the main technical indicators, such as the type of phosphating film and film, for reference

- Q: What are the specifications for the rigging?

- Because the demand is more difficult to buy, to ask the producer of several wire rope, please note in the purchase, purchase invoice must indicate the name of wire rope, such as phosphate coated wire rope, prevent illegal infringement of their legitimate rights and interests of enterprises, in addition, patent products are generally in the rope on the outer packing of a patent spraying mark, warranty due the main technical indicators, such as the phosphating film type and film weight (have an important impact on the weight of phosphating film size, wear resistance and corrosion resistance of the service life of the wire rope, for reference only)

- Q: Notice of tower crane?

- Tower cranes shall not operate near overhead transmission lines. If they are limited to field conditions, they must take safety measures when operating alongside the line. The safe distance between tower crane and overhead transmission line shall comply with the regulation.

- Q: Does the pressing rope have any influence on the tension value of the wire rope?

- Lifting equipment commonly used wire rope varieties of phosphating coating steel wire rope, galvanized steel wire, stainless steel wire rope or coated steel wire rope.

Send your message to us

High Strength Mooring Rope,polyester, High Molecular Polythylene (UHMWPE).

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 pc

- Supply Capability:

- 0 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches