High-Temperature Insulating Fire Bricks

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Insulation Fire Brick

CMAX Insulation Fire Brick are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

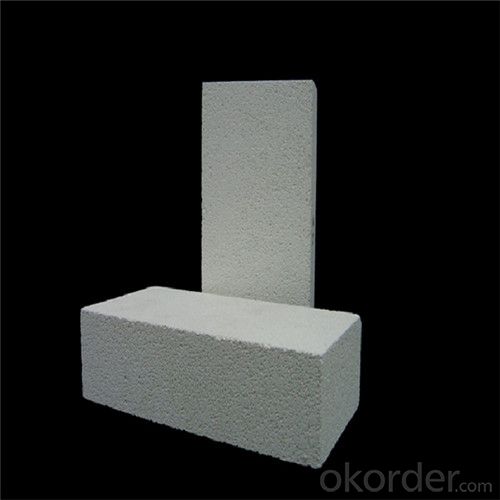

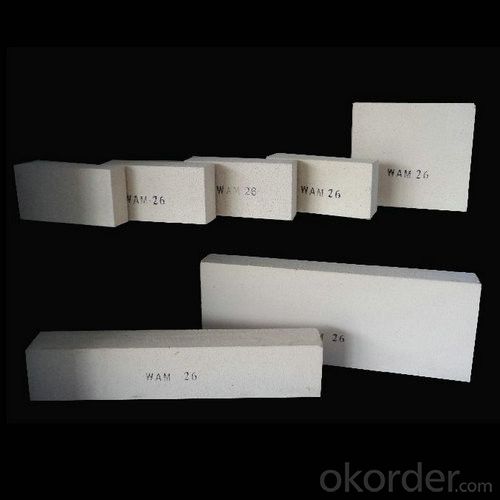

Image of Insulation Fire Brick

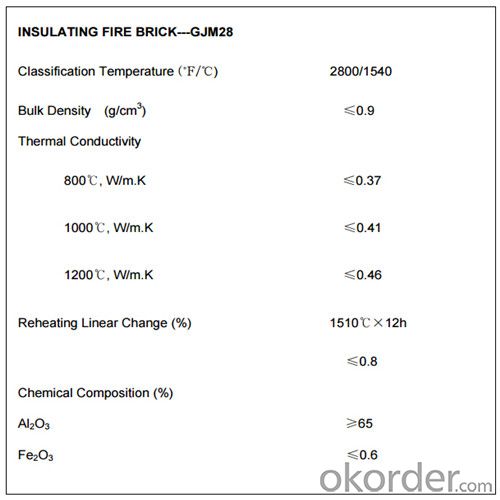

Technical Data of Insulation Firebricks

Feature of Insulation Fire Brick

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application of Insulation Fire Brick

CMAX Insulation Fire Brick can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

Why Choose Us

l We are a government owned company with ISO certificate.

l We are listed in Global Fortune 500 with D & B report.

l We have more than 11 refractory production facilities and bases across China. We have a wide products range, such as ceramic fiber products (ceramic fiber blanket, module, board, paper, bulk), ceramic fiber textile (ceramic fiber rope, cloth, tape, yarn) etc, refractory brick (fireclay brick, high alumina brick, silica brick, magnesia brick etc), monolithic refractory materials, insulating fire brick, calcium silicate board, mica sheet, steel fiber. You can find various products here, and we can combine the light weight ceramic fiber products with the heavy weight refractory brick in one container delivery, then save the sea freight for you.

l We have strict materials selecting system and quality control system. We have the ability to take responsibility for your orders and product quality.

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervis

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q: How do insulating fire bricks prevent heat transfer?

- Insulating fire bricks prevent heat transfer by their unique composition and structure. They are made of lightweight refractory materials that have low thermal conductivity. This means that they are poor conductors of heat, which helps to minimize the transfer of heat from one side of the brick to the other. Additionally, the bricks are designed with small air pockets or voids, which further reduces heat conduction by trapping air and preventing its movement. The combination of low thermal conductivity and trapped air pockets effectively hinders the transfer of heat, making insulating fire bricks an excellent choice for applications where heat insulation is required.

- Q: Can insulating fire bricks be used in the construction of heat storage units?

- Yes, insulating fire bricks can be used in the construction of heat storage units. Insulating fire bricks are designed to withstand high temperatures and have excellent thermal insulation properties. They are commonly used in applications where heat retention is important, such as in furnaces, kilns, and heat storage units. These bricks have low thermal conductivity, which means they can effectively retain and store heat for longer periods of time. This makes them ideal for heat storage units where the goal is to capture and store heat energy for later use. In addition, insulating fire bricks are lightweight and easy to work with, making them a practical choice for construction projects. Overall, insulating fire bricks are a suitable and reliable option for incorporating into heat storage unit construction.

- Q: Can insulating fire bricks be used for insulation in power boiler walls?

- Yes, insulating fire bricks can be used for insulation in power boiler walls. Insulating fire bricks are designed to provide excellent thermal insulation, high temperature resistance, and low thermal conductivity. These properties make them suitable for use in power boiler walls, where insulation is crucial to reduce heat loss and improve energy efficiency.

- Q: Can insulating fire bricks be used in the construction of pottery molds?

- Yes, insulating fire bricks can be used in the construction of pottery molds. Insulating fire bricks are designed to withstand high temperatures and provide excellent heat insulation, making them suitable for pottery molds that require heating in kilns. They can help retain heat and distribute it evenly, resulting in better firing and glazing of pottery.

- Q: Are insulating fire bricks resistant to warping?

- Yes, insulating fire bricks are resistant to warping. They are specifically designed to have high thermal stability and low thermal conductivity, which helps to prevent warping even under high temperatures.

- Q: What is the maximum temperature that insulating fire bricks can withstand?

- Insulating fire bricks can withstand temperatures up to 3000°F (1650°C).

- Q: Do insulating fire bricks emit any toxic fumes when heated?

- Insulating fire bricks, also referred to as refractory bricks, have been designed to endure high temperatures and are commonly utilized in furnaces and kilns. These bricks are constructed from materials with low thermal conductivity, thus impeding the transfer of heat easily. When subjected to heat, insulating fire bricks do not discharge any toxic fumes. This is due to their composition, typically consisting of non-toxic substances like clay or silica. These materials possess chemical stability and do not release any harmful gases or substances when exposed to elevated temperatures. It is significant to acknowledge that although insulating fire bricks themselves do not emit toxic fumes, the substances undergoing heating inside the furnace or kiln may generate fumes or gases that could pose health hazards. Therefore, it is vital to adequately ventilate the area and adhere to safety guidelines when working with any materials that could release toxic fumes during the heating process. In conclusion, insulating fire bricks, made from non-toxic materials, do not emit toxic fumes when heated. Nevertheless, it is essential to ensure proper ventilation and follow safety precautions when working with materials that may emit hazardous fumes.

- Q: Are insulating fire bricks resistant to flame spread?

- Yes, insulating fire bricks are resistant to flame spread.

- Q: What kind of mortar is used to bond insulating fire bricks together?

- The most common type of mortar used to bond insulating fire bricks together is refractory mortar. Refractory mortar is specifically designed to withstand high temperatures and provide excellent adhesion properties for firebrick applications. It is composed of a mixture of high-temperature resistant materials such as silica, alumina, and fire clay. This type of mortar is highly resistant to thermal shock and can withstand extreme temperatures, making it ideal for bonding insulating fire bricks that are used in furnaces, kilns, and other high-temperature applications.

- Q: Can insulating fire bricks be used in the construction of industrial boilers?

- Yes, insulating fire bricks can be used in the construction of industrial boilers. These bricks are designed to withstand high temperatures and provide excellent insulation, making them ideal for use in boiler systems where heat retention and efficiency are crucial. They help to prevent heat loss and ensure efficient energy transfer, making them a popular choice for industrial boiler applications.

Send your message to us

High-Temperature Insulating Fire Bricks

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords