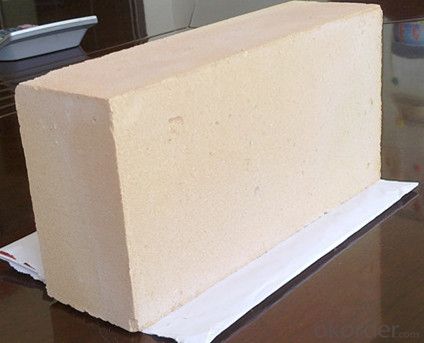

Insulating Fire Brick for Blast Furnace and Industrial Kiln

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNBM conforms strictly to the requirements of ISO 9000 quality control system during the production. MSDS is also available if you want. The thermal insulation fire clay brick meet with the requirements of ASTM & JIS standards. So pls stay cool with our quality.

Insulating Fire Brick Technical index

Product No. | IFB70 | IFB60 | IFB50 | IFB40 |

Al2O3 | 68%-72% | 58%-62% | 48%-52% | 38%-40% |

Refractoriness (°C ) | ≥1790 | ≥1790 | ≥1790 | ≥1790 |

Bulk density (g/cm3) | 2.50-2.60 | 2.35-2.45 | 2.20-2.30 | 2.10-2.20 |

Apparent porosity (%) | 22 | 19-22 | 17-20 | 17-20 |

Cold Crushing strength (kg) | 480-510 | 450-480 | 430-450 | 390-430 |

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

3 large flexible crushing and sieving lines for grit production lines

2 units of 2000KVA furnaces for Boron Carbide fusion

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

(6)Free sample

FAQs

Q1 |

What’s the transport method? |

A1 | FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo. |

Q2 |

What’s the required payment term? |

A2 | Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation. |

Q3 |

Which country are our products exported to? |

A3 | Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations. |

- Q: Can insulating fire bricks be cut to custom sizes?

- Yes, insulating fire bricks can be cut to custom sizes. These bricks are made from lightweight materials such as ceramic fibers, which make them easier to shape and cut according to specific requirements.

- Q: Are insulating fire bricks resistant to flame penetration?

- Yes, insulating fire bricks are resistant to flame penetration.

- Q: Can insulating fire bricks be used in ceramic industry kilns?

- Indeed, insulating fire bricks find utility in the kilns of the ceramic industry. These bricks are specially crafted to endure extreme temperatures and offer insulation within kilns. With their low thermal conductivity, they facilitate the preservation of uniform heat distribution, thus enhancing the efficiency of firing procedures. Moreover, their lightweight nature simplifies their handling and installation in kilns. The bricks' capacity to retain heat and withstand thermal shock renders them an optimal selection for employment in ceramic industry kilns.

- Q: Can insulating fire bricks be cut or shaped as needed?

- Yes, insulating fire bricks can be cut or shaped as needed. They are typically made from lightweight materials such as ceramic fibers, which can be easily cut using a saw or other cutting tools. Additionally, they can be shaped using a knife or sandpaper to achieve the desired form.

- Q: Are insulating fire bricks suitable for insulation in boilers?

- Insulating fire bricks prove to be a suitable option for insulation in boilers. Made from lightweight materials like clay and alumina, these bricks possess exceptional insulation properties. With their low thermal conductivity, they effectively impede heat transfer and significantly diminish heat loss in boilers. Moreover, insulating fire bricks exhibit resistance towards high temperatures, making them ideal for boilers that generate intense heat. They are also durable, capable of enduring the harsh conditions found within boilers, including exposure to corrosive gases and intense heat. Ultimately, the thermal efficiency and high-temperature endurance of insulating fire bricks make them a popular choice for boiler insulation.

- Q: Can insulating fire bricks be used in the construction of lime kilns?

- Yes, insulating fire bricks can be used in the construction of lime kilns. These bricks are specially designed to withstand high temperatures and provide excellent insulation, making them suitable for lining the interior of lime kilns. Their ability to retain heat and reduce heat loss can help enhance the efficiency and performance of the lime kiln.

- Q: Are insulating fire bricks safe to use?

- When used correctly and according to the manufacturer's instructions, insulating fire bricks are generally safe to use. These bricks are specifically designed to endure high temperatures and provide exceptional insulation, making them perfect for applications like lining kilns, furnaces, and fireplaces. Made from lightweight materials like alumina, silica, and other refractory materials, insulating fire bricks aim to minimize heat transfer, thus preventing the escape of heat from the enclosed area. This not only enhances the system's energy efficiency but also reduces the risk of overheating and potential fires, improving safety. To ensure the safe use of insulating fire bricks, it is crucial to install them properly and securely. This involves providing sufficient support and reinforcement to prevent collapse or shifting of the bricks. Additionally, it is essential to use suitable mortar or refractory cement to firmly join the bricks together, creating a sturdy and stable structure. While insulating fire bricks themselves are generally safe, it is important to note that they may contain small amounts of trace elements or materials that can be harmful if released into the environment. Therefore, it is advisable to follow the manufacturer's safety guidelines, which may include wearing protective gloves, goggles, and a dust mask when handling the bricks. In conclusion, insulating fire bricks are a safe and dependable choice for insulation in high-temperature applications. Nevertheless, it is crucial to take necessary precautions during installation and adhere to safety guidelines to ensure their proper and safe use.

- Q: Can insulating fire bricks be used in chimney liners?

- Yes, insulating fire bricks can be used in chimney liners. They are designed to withstand high temperatures and provide insulation, making them suitable for use in chimneys to improve efficiency and prevent heat loss.

- Q: What is the thermal expansion of insulating fire bricks?

- The thermal expansion of insulating fire bricks is relatively low, typically around 0.5% to 1%.

- Q: Can insulating fire bricks be used in the construction of glass melting furnaces?

- Yes, insulating fire bricks can be used in the construction of glass melting furnaces. Insulating fire bricks are designed to have a high resistance to heat and are capable of withstanding extremely high temperatures. They have low thermal conductivity, which means they can effectively retain heat and minimize heat loss. In glass melting furnaces, where temperatures can reach up to 1600°C (2912°F) or even higher, insulating fire bricks play a crucial role in maintaining the desired temperature inside the furnace. By using insulating fire bricks as the furnace lining, the heat generated during the melting process can be efficiently contained within the furnace, allowing for better energy efficiency and reduced heat loss. Furthermore, insulating fire bricks are lightweight and have good thermal shock resistance, which makes them ideal for use in glass melting furnaces where rapid temperature changes are common. This ensures that the bricks will not crack or break under the extreme conditions of the furnace. Overall, the use of insulating fire bricks in the construction of glass melting furnaces provides better insulation, energy efficiency, and durability, making them a suitable choice for this application.

Send your message to us

Insulating Fire Brick for Blast Furnace and Industrial Kiln

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords