High Strength Polyester Woven Geogrids / Biaxial Fiberglass Geogrids

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Fiberglass Geogrid:

Fiberglass geogrid is based on fiberglass woven cloth coated with modified bitumen or PVC, it was developed to address the problem of pavement cracking on highways, roads and runways, driven by a need to reduce cost for infrastructure maintenance and repair.

It is characterized by high tensile strength in axial and lateral directions, low stretch rate, alkali-resistance, low temperature- resistance, as well as convenience in construction and low price. It can be used on pitch pavement to prevent cracks and prolong pavement service life. It also can be used as a basal reinforcement material for hillsides, reservoirs, harbors, ports, water channels, seawalls, etc.

Performance of Fiberglass Geogrid:

--- High strength, high modulus and low temperatures resistance.

Applications of Fiberglass Geogrid:

--- Reinforcement for road pavement

--- Reinforcement for railway basement

--- Reinforcement for Tunnel

--- Reinforcement for Slope

--- Reinforcement for embankment.

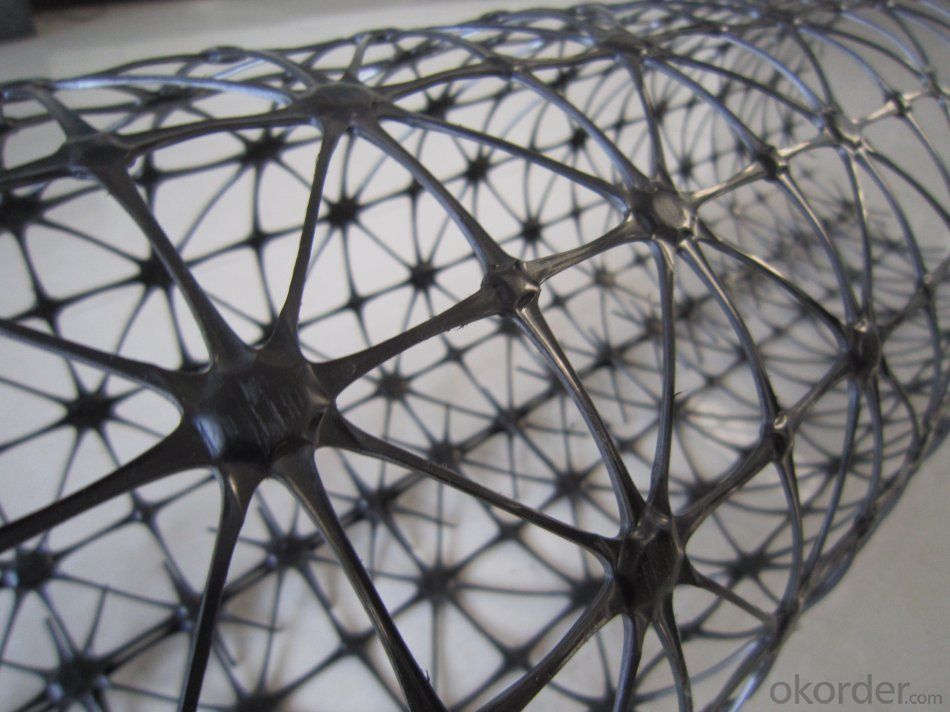

Introduction of PP Biaxial Geogrid:

Biaxial geogrid, made of high molecular polymer, is extruded into sheet and then punched into regular mesh pattern, and finally stretched in longitudinal and transverse directions.

Features of PP Biaxial Geogrid:

1. With high tensile strength in longitudinal and transversedirections

2.This structure can provide an chain system of more effective force bearing and spreading for the soil.

Application of PP Biaxial Geogrid:

Mainly applied in highway, railway, slope protecting projects etc.

1)strengthen land loading capacity and extend its service life.

2) convenient to construct ; reducing project cost and maintenance cost.

Features of Polyester Geogrid:

1) High tensile strength

2) High tear-resistant

3) Strong combination with gravel and soil

Application of Polyester Geogrid:

It mainly applied in strengthening soft ground of rail and road.

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: Can geogrids be used in reinforced concrete pavements?

- Yes, geogrids can be used in reinforced concrete pavements. Geogrids are commonly used as a reinforcement material in concrete pavements to enhance their strength, durability, and load-bearing capacity. By distributing and restraining the forces within the concrete, geogrids help to minimize cracking and improve overall pavement performance.

- Q: What are the differences between geogrids and geocomposites?

- Geogrids and geocomposites are both used in soil stabilization and reinforcement applications, but they have some key differences. Geogrids are typically made from high-strength polymers or fiberglass, and they have a grid-like structure with open spaces. They are designed to provide tensile strength and distribute loads across a wider area. Geogrids are mainly used for reinforcing soils, retaining walls, and roadways. On the other hand, geocomposites are multi-layered materials that combine different geosynthetic components. They usually consist of a geotextile fabric or membrane bonded to a geogrid or geonet layer. Geocomposites offer a combination of functions such as filtration, drainage, separation, and reinforcement. They are commonly used in applications like erosion control, landfill engineering, and drainage systems. In summary, while geogrids focus on reinforcement and load distribution, geocomposites offer a more versatile solution by combining multiple functions in a single product.

- Q: How do geogrids improve the performance of asphalt pavements?

- Geogrids improve the performance of asphalt pavements by providing reinforcement and stability. They effectively distribute the load across the pavement structure, reducing cracking and rutting. Additionally, geogrids enhance the overall strength and durability of the pavement, thus extending its lifespan and reducing maintenance costs.

- Q: The ground treatment is full of geogrid is not along the line direction

- Because the geogrid is rolled

- Q: What are the physical properties of Geosynthetics

- What are the physical properties of geosynthetics? 1, thickness: the thickness of geosynthetics mm. The variation of thickness has a great influence on the porosity, permeability and filtration properties of the fabric. Commonly used the thickness of all kinds of geosynthetics: geomembrane 0.25 ~ 0.75mm, the thickest of up to 2 ~ 4mm;

- Q: How do geogrids enhance the performance of reinforced embankments?

- Geogrids enhance the performance of reinforced embankments by providing additional tensile strength and stability to the soil layers. They help to distribute the load more evenly, reducing the potential for settlement and improving the overall stability of the embankment. Additionally, geogrids help to control lateral spreading of the soil, preventing slope failure and increasing the lifespan of the embankment.

- Q: Who knows how much the staggered distance of the lap joint is

- The staggered distance of the lap joint shall not be less than 300 mm. The concrete specification (geotextile laid overlapping: when) using geotextile as filter layer, should be laid in place in the bottom and sides of the trench wall, soil and reserve covering the top required fabric, straighten ride close to the lower layer, all vertical or horizontal joints should be staggered alternately. The lap length shall not be less than 300MM.A grille is made of polypropylene, PVC polymer and thermoplastic or molded by two-dimensional grid or a certain height of the three-dimensional mesh screen, when used as a civil engineering, called geogrid.

- Q: Can geogrids be used in retaining walls for waterfront parks?

- Yes, geogrids can be used in retaining walls for waterfront parks. Geogrids provide reinforcement and stability to the soil, preventing erosion and maintaining the integrity of the retaining wall. They are commonly used in such applications to enhance the strength and durability of retaining walls in waterfront parks.

- Q: What are the design considerations for geogrids in reinforced soil slopes?

- Some design considerations for geogrids in reinforced soil slopes include the type and strength of the geogrid material, proper installation techniques, adequate spacing and orientation of the geogrid layers, and the required length and width of the geogrid reinforcement. Additionally, factors such as the soil properties, slope geometry, and anticipated loads must be considered to ensure the geogrids can effectively stabilize the slope and prevent soil erosion or failure.

- Q: What is the difference between geocell and geogrid

- Geocell:Product Description: geocell is made of high strength HDPE broadband, through a strong welding and the formation of a network of grid room structure. The utility model has the advantages of flexible expansion, and can be folded when being transported, and when the utility model is used, the utility model can be filled with earth and stone or concrete materials, and the structure of the utility model has the advantages of strong lateral confinement and large steel. The utility model can be used as a cushion to deal with the bearing capacity of the foundation with the soft foundation, and can also be arranged on the slope to form a slope protection structure, and can also be used for constructing the retaining structure, etc..

Send your message to us

High Strength Polyester Woven Geogrids / Biaxial Fiberglass Geogrids

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords