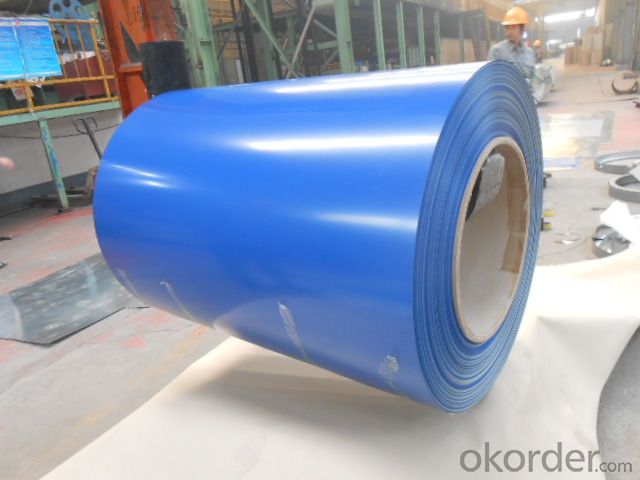

high quality ppgi/cold rolled steel coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

high quality ppgi/cold rolled steel coil size

Product Description

| Raw material | SGCC, SPCC, DC51D, SGHC,A653 |

| Certificate | ISO9001 |

| Thickness | 0.14mm-0.7mm |

| Width | 1250mm or under |

| Tolerance | thickness+/-0.01mm |

| Surface treatment | galvanized / galvalumized steel sheets |

T Bending (top-coating) T Bending (back-coating) | ≤3T ≤4T |

| Anti-MEK Wiping | ≥100times |

| Zinc coating | 40-180g |

| Type of coating structure | 2/1 or 2/2 coating, or customized |

| Standard | GB/T12754-2006, GB/T9761-1988, GB/T9754-1988, GB/T6739-1996, HG/T3830-2006, HG/T3830-2006, GB/T1732-93, GB/T9286-1998, GB/T1771-1991, GB/T14522-93 |

| Color | customized |

| Application | Building industry ,structural use, roofing, commercial use ,household appliance,industry facilities,office buildings |

Our Services

1. Competitive price:

We produce resin and paint by ourself, which greatly reduce our cost!

2. Accuracy:

We have a technician team of 40 people and a QC team of 30 poeple, ensure our products is exactly what you want.

3. Materials:

All color Steel Sheets are made of high-quality raw materials.

4.Certificate:

Our products are certified by ISO9001

5. Productivity:

We have three large-scale production line, to guarantee all your orders will be finished in earlist time

PPGI

I Specifications:

1. Thickness: 0.14-0.8mm

2.Width:600-1250mm

3. Material: SGCC, SGCD, SECC, SECD, DX51D+Z

4.Zinc coating: 30-180G/M2

5. Surface Structure: Galvanized, zero spangle, regular spangle or normal spangle

6. COLOR: RAL number or sample color

Topside: 5micron primer +15-20microns polyester

Backside: 5-8microns primer epoxy.

7. Surface treatment: chromated and oiled, chromated and non-oiled

II Main characteristics:

1. Strong corrosion resistance

2. Surface quality

3. Conducive to deep processing, such as corrugated steel sheet 4.economy and practicality

III Applications:

Household Appliance:

1.Refrigerator shutter &side panels, Washer, Freezers, Air conditions,

2.Rice Cooker, Microwave Ovens, Water Heaters, Sterilization Cabinets, Range Hoods

3.Computer Panels , DVD/DVB panels, TV back panel etc.

Teaching Board: whiteboard, blackboard, green board (chalk board).

Indoor Decoration: Fireproof Door, kitchen cabinet, wall decoration.

- Q: Can steel coils be welded together?

- Indeed, it is possible to weld steel coils together. The practice of welding is widely employed in the fusion of metals, including steel coils. It entails the melting of the coil edges and their subsequent amalgamation with a filler material. This procedure generates a sturdy and long-lasting bond between the coils, enabling their unification into a singular entity. The act of welding steel coils together is frequently carried out across a range of industries, such as manufacturing, construction, and automotive, in order to fabricate larger structures or components. However, it is crucial to adhere to proper welding techniques and implement stringent quality control measures to guarantee the integrity and potency of the weld joint.

- Q: What are the challenges in coil slitting for narrow strip widths?

- There are several challenges associated with coil slitting for narrow strip widths. One of the main challenges is maintaining accuracy and precision during the slitting process. When dealing with narrow strip widths, even the slightest misalignment or deviation can result in significant defects or inconsistencies in the final product. This requires careful calibration and adjustment of the slitting equipment to ensure that the strips are cut with utmost accuracy. Another challenge is the risk of material damage or deformation during the slitting process. Narrow strip widths are more prone to distortion, wrinkling, or edge cracking, especially if the material is not properly handled or supported during slitting. Special care must be taken to ensure that the material is fed smoothly through the slitting machine and that the tension is properly controlled to minimize any potential damage. Additionally, narrow strip widths can pose challenges in terms of handling and transporting the slit coils. These coils are more susceptible to bending, twisting, or telescoping, which can lead to difficulties in stacking, storage, or transportation. Proper packaging and handling techniques must be employed to ensure that the slit coils maintain their shape and integrity throughout the supply chain. Furthermore, narrow strip widths often require more frequent blade changes during the slitting process. This increases the complexity and time required for setup and maintenance, as the blades need to be carefully selected and replaced to achieve optimal cutting results. It is crucial to have skilled technicians who can handle these blade changes efficiently and effectively. Overall, while coil slitting for narrow strip widths offers various benefits such as cost savings and increased material utilization, it also presents several challenges that need to be carefully addressed. These challenges include maintaining accuracy, preventing material damage, ensuring proper handling and transportation, and managing blade changes effectively. By understanding and addressing these challenges, manufacturers can optimize their coil slitting operations and produce high-quality narrow strip products.

- Q: I looking at replacing a few of the panels on my car with either Carbon Fiber or High Tensile Steel to shave off some weight and increase mpg and take some time off my quarter mile. Which is better: Carbon Fiber or High Tensile Steel?

- Steel is much cheaper to buy, but weighs more than the carbon fiber and is not as strong as a rule. To save weight on a race car go with carbon fiber. To save weight (money) on the wallet go with steel.

- Q: Can steel coils be coated with self-cleaning materials?

- Yes, steel coils can be coated with self-cleaning materials. These materials are typically hydrophobic or photocatalytic coatings that help prevent dirt, dust, and other contaminants from sticking to the surface of the steel. The self-cleaning properties of these coatings allow for easier maintenance and longer-lasting aesthetics of the steel coils.

- Q: I received a very nice set of stainless steel cookware as a wedding gift. While very pretty, Im finding them almost useless for cooking. Everything sticks, they're difficult to clean, and Im using my old non-stick pans instead. Should I simply leave the stainless out for decortive purposes, or are stainless steel pans better for some applications?

- I can't understand why you're having difficulty. My pans are as good as the day they were bought.I would never return to non-stick after having my stainless steel pans! Non stick coatings come off in the food-yuk! What are you cooking in them? Are you trying to wash them in the dishwasher? That never works well. I always put water in mine if I've done a custard or stew, beans or things like that, for a little soak before washing by hand in hot soapy water. They really are great even when I have burnt something, because you can scrape the burn with a sharp implement and you do no damage at all to the pan. I highly recommend them.

- Q: How are steel coils loaded onto trucks or containers?

- Steel coils are typically loaded onto trucks or containers using specialized equipment such as cranes, forklifts, or coil trailers. The coils are lifted and secured onto the truck or container using straps, chains, or clamps to ensure safe transportation.

- Q: I know aluminum is lighter but I'm looking at a 01 bianchi grizzly mountain bike which is steel. I used to ride a specialized stumpjumper m4 which was aluminum. It was quite light so I don't know if I'll like a bit heavier bike but overall what is better from those who have had both?

- Depending on the price, aluminum may be as heavy or heavier than steel... don't let anyone tell you otherwise. Keep in mind that with age aluminum will eventually break from stress while steel will never fail due solely to riding stresses. In all, it is up to you. I ride steel or magnesium road bikes and aluminum or magnesium MTBs.

- Q: How are steel coils used in the manufacturing of industrial machinery?

- Steel coils are commonly used in the manufacturing of industrial machinery to form various components, such as shafts, gears, and frames. These coils are typically cut, shaped, and welded into the desired forms to create strong and durable parts that can withstand heavy loads and high temperatures. Additionally, steel coils are often used as raw materials for fabricating machine tools, molds, and dies, which are essential for the production of industrial machinery.

- Q: Steel is a mixture of Iron Carbon . So , is steel a metal or non - metal ?

- steel is an alloy - mix of two meatls alloy is a mixture and metal is an element so no comparision

- Q: How are steel coils used in the production of storage tanks?

- Steel coils are typically used as the raw material in the production of storage tanks. These coils are formed into sheets and then shaped and welded to create the tank's body. The strength and durability of steel make it an ideal choice for storing various substances, including liquids and gases, ensuring the safety and longevity of the storage tanks.

Send your message to us

high quality ppgi/cold rolled steel coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords