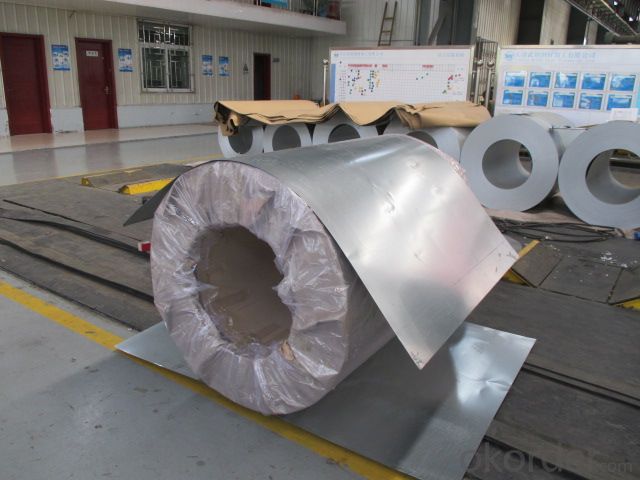

PPGI/HDGI prepaid Galvanized steel coils

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description :

Raw material | SGCC, SPCC, DC51D, SGHC,A653 |

Certificate | ISO9001.ISO14001.OHSAS18001 |

Thickness | 0.16mm-0.7mm |

Width | 1250mm or under |

Tolerance | thickness+/-0.01mm |

Surface treatment | galvanized / galvalumized steel sheets |

T Bending (top-coating) T Bending (back-coating) | ≤3T ≤4T |

Anti-MEK Wiping | ≥100times |

Zinc coating | 40-180g |

Type of coating structure | 2/1 or 2/2 coating, or customized |

Standard | GB/T12754-2006, GB/T9761-1988, GB/T9754-1988, GB/T6739-1996, HG/T3830-2006, HG/T3830-2006, GB/T1732-93, GB/T9286-1998, GB/T1771-1991, GB/T14522-93 |

Color | customized |

Application | Building industry ,structural use, roofing, commercial use ,household appliance,industry facilities,office buildings |

- Q: How are steel coils used in the manufacturing of electrical transformers?

- Steel coils are used in the manufacturing of electrical transformers as they provide structural support and act as a core for the transformer. The steel coils are wound with copper wire to create the primary and secondary windings, which help in transferring electrical energy efficiently.

- Q: what pokemon are week to steel type pokemon like lucario? help please, and thank you.

- Hi! well i hav both games but ther's no big difference. I play Diamond more though. For starter u shud pick piplup: 1. because u love water pokemon of course 2. piplup is stong against chimchar (water- fire) 3. it can learn ice moves like ice beam which are super effective against torterra. 4. Empoleon looks Wicked!! and its steel type backs up its weaknesses. i liked it. hav fun with the game!!!!!!!

- Q: What is the average amount carbon emissions of steel per pound produced?

- Carbon okorder /... - Similar pages - Life-cycle energy and emissions of marine energy devices | Carbon ...Carbon dioxide emissions per unit mass of steel: 1.75 tCO2/tonne steel ; Total mass of steel in device: 665 tonnes ; Carbon dioxide emissions due to .

- Q: What is the strongest steel ever made.

- *NS110 steel used in Oyashio seems to be the strongest steel . Its tensile strength is not less than 110kg/mm^2 which is equal to 1078 mpa or about 157000 psi *HY 100 (not less than 100000psi and not more than 120000 psi) *HLSE100 (approximately 142850 psi). and can have more tensile strength.

- Q: What are the common methods of cutting steel coils?

- The common methods of cutting steel coils include shearing, slitting, and laser cutting. Shearing involves using a machine with two blades to cut through the coil. Slitting involves passing the coil through a set of rotating circular blades to create narrower strips. Laser cutting uses a high-powered laser beam to cut through the steel coil with precision.

- Q: a picture of the atomic structure of carbon steel

- This is actually a quite complex question... The atomic arrangement in steels can be controlled over a pretty wide range of different structures. This is really the fundamental reason why steel is such a commonly used material. The different atomic structures produce different physical properties so metallurgists have developed many different processes to control the atomic structure to get the properties they want. One simple answer is that Fe is BCC, body centered cubic at room temperature at equilibrium conditions. When you heat Fe up, it transforms to FCC, face centered cubic. If you continue heating Fe, it goes back to BCC, then it melts. The addition of C makes these structures (and the transformation temperatures) different. Deviating from equilibrium conditions by, for example, cooling very quickly (quenching) creates different atomic structures (one of the most important is known as martensite). Depending on how much C is in the steel, you can also have two different atomic structures (two different phases) present in equilibirum, for example, pearlite which is a mix of alpha Fe (BCC) and iron carbide Fe3C (orthorombic crystal structure). So... you need to think a little more about exactly what you want a picture of. I hope this helps

- Q: for instance Cr-Ni steeldoes this refer to plated steel or a uniform mixture

- stainless steel is an alloy normally iron with additions of C, Mn, Ni, Cr, and Nb - amounts added depend on properties required. Corrosion resistance is due to a very thin but dense layer of chromium oxide which forms at the surface and prevents further attack. Ordinary steel on the other hand becomes coated with a porous layer of iron oxide(rust) through which the atmosphere can pass and cause further corrosion.

- Q: Is Stainless steel called that because.....a. Its stains lessORb. Its virtually stainless (it can't stain).Lol do you know the correct answer?????

- a. is the correct answer. It will still show tea and coffee stains. I find using baking soda is a good way to clean it and freshens the drains of the sinks as well. If cleaning your refrigerator a glass cleaning spray works well, just be sure to dry it thoroughly.

- Q: The length of a steel beam increases by 0.78 mm when its temperature is raised from 22 degrees C to 35 degrees C. What is the length of the beam at 22 degrees C (in meters)?I used: L = (0.78 mm)/[(9/5)(.00000645 F)(13)] = 5.17 meters but Mastering Physics said Not quite. Check through your calculations; you may have made a rounding error or used the wrong number of significant figures. I'm confused because this is how we learned this kind of problem in class, so if anybody knows what I did wrong, feel free to correct my errors! Thanks

- we may use the formula ΔL=α(Lo)(Tf-To) where Lf is the length of steel at temp. Tf Lo is length at To α is the coefficient of linear expansion of steel which is 11x10^-6/°C ΔL=0.78mm (the change in length) Lo=? ΔL=α(Lo)(Tf-To) Lo=ΔL/[α(Tf-To)] Lo=(0.78x10^-3m)/[(11x10^-6/°C)(35°C-2...? Lo=5.455m answer

- Q: How are steel coils inspected for yield strength?

- Yield strength inspection of steel coils involves a series of testing methods. The most commonly used method is the tensile test, where a small sample is taken from the coil and subjected to a controlled load until it reaches its yield point. In the tensile test, the sample is progressively stretched until it deforms and ultimately fractures. Throughout this process, the load and elongation data are continuously recorded. The yield strength is then determined by pinpointing the point on the stress-strain curve where the material starts showing plastic deformation or permanent elongation. Another approach to inspecting steel coils for yield strength is the hardness test. Since hardness is often linked to yield strength, a hardness test can estimate the material's yield strength. This test involves measuring the steel coil's surface resistance to indentation or penetration using instruments like a Rockwell or Brinell hardness tester. Moreover, non-destructive testing methods like ultrasonic testing and magnetic particle inspection can also be utilized to assess yield strength. Ultrasonic testing employs high-frequency sound waves to detect any internal defects or inconsistencies in the material's structure. On the other hand, magnetic particle inspection relies on the application of magnetic fields and the usage of magnetic particles to identify surface cracks or defects. In conclusion, there are various testing methods available to inspect steel coils for yield strength. These methods offer valuable information to manufacturers and inspectors regarding the steel's quality and performance capabilities, ensuring that it meets the required standards and specifications.

Send your message to us

PPGI/HDGI prepaid Galvanized steel coils

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords