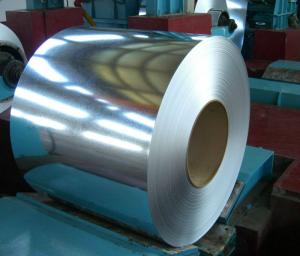

High Quality Hot Dip Galvanized Steel Coil Made In China DX51D/Z275 Q235

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

DESCRIPTION FOR GALVANIZED STEEL COILS:

1) Size: 0.30-2.0mm x 1,000-1,500mm x C

2) Zinc coating: 80-275g/m2;

3) Spangle: regular, zero and minimized

4) Material: we can supply different qualities according to several standards,

such as:

a) SGCC, SGCD, SGCE according to JIS G3302

b) DX51D+Z, DX52D+Z, DX53D+Z, DX54D+Z to EN 10142

EXPORT STANDARD FOR GALVANIZED STEEL COILS:

-Axial and circumferential steel straps with seal (4 steel straps each)

-VCI Anti-rust kraft paper

-Water-proofing plastic

-Pearl wool (coil surface)

-Steel cover (coil surface/bore)

-Plastic cover (coil sides)

-Inside and outside corner protectors

Or According customers' requirements(Usually only for domestic)

RAW MATERIALS FOR GALVANIZED STEEL COILS:

(1)Hot dipped galvanized steel sheet

(2)color coated galvanized steel sheet

(3)Galvalume steel sheet

(4)Prepainted galvalume steel sheet

(5)Aluminum sheet

(6) Prepainted aluminum sheet

(7)Stainless steel sheet

PACKAGING &DELIVERY FOR GALVANIZED STEEL COILS:

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

TRADE TERMS FOR GALVANIZED STEEL COILS:FOB, CFR, CIF

DETAILED PICTURES FOR GALVANIZED STEEL COILS:

APPLICATION FOR GALVANIZED STEEL COILS:

Guardrails, ventilation ducts, gutters and down spouts, Pre-paint and post paint applications, gutters and ceiling suspension bars, shutter door rails. Auto parts, electrical appliances, refrigerator appliances, signs, automotive parts,vending machines, washing machines, showcases and other structural use, roofing, commercial use.

FAQ FOR GALVANIZED STEEL COILS:

Q:How about the delivery time?

A:Within 15-30days after receiving the deposit or L/C at sight.

Q:How about the trade terms?

A:EXW,FOB,CFR,CIF will be accepted.

Q: How can I get the samples?

A: If you need some samples to test ,please pay for the transportation freight of samples and our samples are free for you.

Q: How can I get your price list?

A: Please send us your email or fax and order information – Quantity, Specification (steel type, thickness, width, surface finish), then I can send you the price list.

- Q: What is the weight of a steel coil?

- The weight of a steel coil can vary depending on its size and thickness. Generally, a steel coil can weigh anywhere from a few hundred kilograms to several tonnes.

- Q: Don't ask me why, but I took my stainless steel ring and I heated it up with my gas stove. I stuck it in there til the metal turned red, and the flame which is normally blue turned orange for some reason when the metal turned red. Anyway, afterwards i cooled it off in water and now it's all discolored and it feels different. It's weighs less and it doesn't feel the same. Plus, it's ugly cause it's all black and blue. What happened? Someone help

- I would first check it with a magnet. If it is attracted to the magnet it has too much steel in it and that is what oxidized,not the CR. U might try to clean it with a good acid .

- Q: How are steel coils inspected for quality control?

- Steel coils are inspected for quality control through a series of rigorous tests and inspections. This typically involves visual checks for any surface defects, such as scratches or dents, as well as measurements of dimensions, weight, and thickness. Additionally, non-destructive testing techniques like ultrasonic or magnetic particle testing may be conducted to detect internal flaws or inconsistencies in the steel. These comprehensive inspections ensure that only high-quality steel coils are approved for use.

- Q: What are the common challenges faced in steel coil production?

- Some common challenges faced in steel coil production include ensuring consistent quality and thickness of the coil, maintaining efficient production rates, managing inventory and storage of coils, addressing issues related to coil surface defects and handling, and adhering to strict safety regulations. Additionally, fluctuations in raw material prices and market demand pose further challenges for steel coil producers.

- Q: What are the different methods of galvanizing steel coils?

- There are several methods of galvanizing steel coils, including hot-dip galvanizing, electro-galvanizing, and continuous galvanizing.

- Q: Steel is a mixture of Iron Carbon . So , is steel a metal or non - metal ?

- Boeing is building the new 787 dreamliner almost completely out of composites. If you take a look at an Ashby chart (Strength vs. Density) you would see that there are composites that are as strong as steel but as dense as aluminum.

- Q: How can I owe a Pre-engineered Steel Building?

- You just have to do small efforts for owing a steel building: Firstly you have to finalize a steel building company for construction work. After finalizing the steel building company, the next step is the paperwork - the agreements and contracts. Some steel building companies may also ask for a verbal approval for the factories to get the work started.

- Q: What are the factors to consider when selecting a supplier for steel coils?

- When selecting a supplier for steel coils, there are a few key factors to consider. Firstly, the quality of the steel coils is crucial. It is important to assess the supplier's reputation, certifications, and track record for delivering high-quality products. Secondly, pricing and cost-effectiveness play a significant role. Comparing prices and negotiating favorable terms with different suppliers is essential to ensure competitive pricing. Additionally, the supplier's reliability and ability to meet delivery schedules must be thoroughly evaluated. Timely delivery is vital to avoid disruptions in production. Lastly, considering the supplier's location, proximity to the manufacturing facility, and their overall customer service and support are also important factors to take into account.

- Q: What website can I use to find a good picture that shows the atomic structure of a carbon steel?

- You know, I'd have to say it's very complex.

- Q: I know copper pots are supposed to be really good for cooking with, and I have been looking around online. One thing I don't want to do, however, is send them in to be re-lined with tin. So I was wondering if stainless steel lined copper pots work as well as the traditional tin lined ones, or if those make the copper just for looks.

- Stainless steel is durable and does not disolve and make things taste funny. Stainless steel is not a good conductor of heat, so it has hot and cold spots. Copper is very good conductor. They noe bond copper to stainless steel to get the best features of each. Some pots just have a very thin copper plating to fool you. A good pot will be heavier, It is really hard to tell from looking.if it is plating or a bonded layer of copper. the thicker the better

Send your message to us

High Quality Hot Dip Galvanized Steel Coil Made In China DX51D/Z275 Q235

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords