Prime Hot Dipped Galvanized Steel Coil Made in China DX51Grade D

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Prime Hot Dipped Galvanized Steel Coil DX51Grade D:

Prime Hot Dipped Galvanized Steel Coil DX51Grade D is developed from old hot plating methods, and it has a history of over 140 years since its application to the industry of France in 1836. However, the hot dip galvanizing industry has been greatly developed in recent three decades with the quick development of cold-strip steel.

They can be used as final products and basic plates of color coated steel coils and widely applied in construction, home appliances, decoration, ect.

2.Applications of Prime Hot Dipped Galvanized Steel Coil DX51Grade D:

(1) Construction and building: roofings, ventilating duct; handrail; partition panel,etc.

(2) Further processing: coating base plate.

(3) Electric appliances: refrigerator; washing machine; recorder; microwave, etc.

3.Prime Hot Dipped Galvanized Steel Coil DX51Grade D Images:

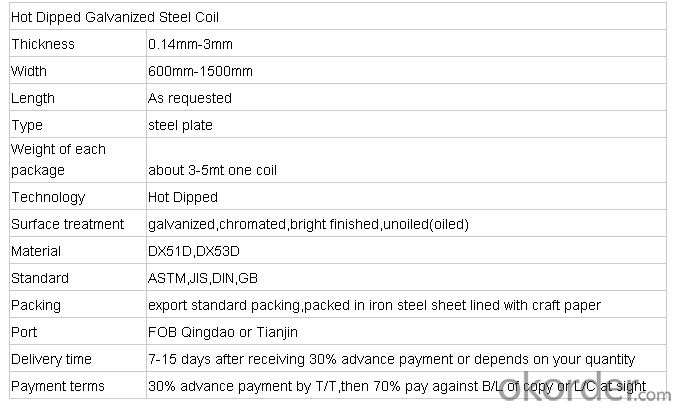

4.Prime Hot Dipped Galvanized Steel Coil DX51Grade D Specification:

5.Our factory

6.FAQ

1. Q:what is the MOQ.?

A:Generally speaking, the MOQ is 5 metric ton per size, if your quantity is small , we can supply you from our stock .

2.Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers. For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for Freight Collect. Also you can have a visit to our factory, welcome to Qingdao!

3.Q:How to know the Quality Guarantee:

A:Visit Our factory is the best way to know each other more.ISO9001:2008 by international quality system Certificate and The Third Inspection can prove our quality.

B :We will attach some relevant photos via email to show our factory, machine and products for you.

- Q: What are the different types of steel coil surface appearances?

- The different types of steel coil surface appearances include mill finish, galvanized, painted, polished, and coated.

- Q: I know of the cheaper steel shot for waterfoul hunting, but there is more expensive shot available. Is it worth the money, how much more distance are we talking, and what do you like the best?(brand name)

- All buckshot I can think of at the moment is lead. Steel shot is used for waterfowl hunting because lead is illegal for that use. They don't want all that lead shot falling back in the water and causing lead contamination. There would be no reason to make steel buckshot, and it would be pretty ineffective. Steel is much less dense than lead. So a steel 00 pellet would weigh much less than a lead 00 pellet. So it would carry a lot less energy to a target. Buckshot is used for just that, Bucks. Well large game like deer, bear, and for self defense. In uses like that you need that extra energy. Lead shot is used for everything, except where lead shot is illegal, which is waterfowl hunting. Steel shot really isn't very popular anymore. Waterfowl shot just can't be lead. It doesn't have to be steel. They've come out with other stuff, like bismuth, that is a lot more dense than steel, but still not as dense as lead.

- Q: Can someone help me...i have a diagram and were supposed to calculate the steel tonnage needed for the pictre. Can someone tell me step by step what i need to do (ex:find area of ...)

- Find the volume of steel and then multiply that by the density of the steel.

- Q: What processes and materials are used in the production of chrome steel

- Go to the process section and find point 6 (explains when alloys are added). Chrome is added at this point, usually in the form of ferrochrome alloy (FeCr). Many kinds of chrome steel also contain nickel. The strengthening effect on steel by forming stable carbide grains at the grain boundaries and the strong increase in corrosion resistance made chromium an important alloying material for steel. The high speed tool steels contain between 3 and 5% chromium.

- Q: What are the different surface treatments available for steel coils?

- There are various surface treatments available for steel coils, including galvanizing, painting, powder coating, and zinc coating. These treatments help protect the steel from corrosion and improve its durability and appearance.

- Q: How are steel coils measured for thickness?

- Steel coils are measured for thickness using a device called a micrometer or a thickness gauge. The micrometer is pressed against the coil's surface, and the measurement is displayed on its calibrated scale, providing an accurate reading of the steel coil's thickness.

- Q: What are the different methods of surface cleaning for steel coils?

- There are several different methods available for surface cleaning of steel coils. The choice of method depends on the specific requirements and conditions. 1. Mechanical Cleaning: This method involves the use of mechanical tools such as wire brushes, sanding discs, or abrasive pads to physically remove dirt, rust, or other contaminants from the surface of the steel coils. It is commonly used for light cleaning and can be done manually or with the help of automated equipment. 2. Chemical Cleaning: Chemical cleaning involves the use of various cleaning agents or solvents to dissolve or loosen contaminants from the surface of steel coils. This method is effective for removing oil, grease, or stubborn dirt. Different chemicals can be used depending on the type of contaminants and the desired level of cleaning. It is important to follow safety guidelines and use appropriate protective equipment when using chemical cleaners. 3. Power Washing: Power washing or pressure washing utilizes a high-pressure water jet to remove loose particles, dirt, or contaminants from the surface of steel coils. This method is effective for large-scale cleaning and can be combined with chemical cleaners for enhanced results. It is important to adjust the water pressure according to the type of surface and use appropriate nozzles to prevent damage. 4. Pickling: Pickling is a chemical cleaning method that involves the immersion of steel coils in an acidic solution, typically a mixture of hydrochloric acid and sulfuric acid. This process removes scale, oxides, and other impurities from the surface of the steel. Pickling is commonly used for heavy-duty cleaning and preparation of steel coils before further processing or coating. 5. Electrolytic Cleaning: Electrolytic cleaning utilizes an electric current to remove contaminants from the surface of steel coils. The coils are immersed in an electrolyte solution, and the application of a direct current causes the contaminants to dissolve or dislodge from the surface. This method is particularly effective for removing rust or corrosion and can be used in conjunction with other cleaning methods. It is important to consider factors such as the type and condition of the steel coils, the level of cleanliness required, and any specific industry standards or regulations when choosing the appropriate method of surface cleaning. Regular maintenance and cleaning of steel coils are essential to ensure their longevity, performance, and resistance to corrosion.

- Q: not iron, steel

- steel was first used in the 1800s in buildings.

- Q: How are steel coils used in the production of electrical resistors?

- Steel coils are used in the production of electrical resistors as they provide a conductive material that can withstand high temperatures. The steel coil is wound into a spiral shape to increase the length of the wire, which in turn increases the resistance. This allows the resistor to regulate the flow of electric current in a circuit, providing the desired level of resistance.

- Q: How are steel coils used in the production of automotive components?

- Steel coils are used in the production of automotive components as they are rolled into flat sheets and then further processed to create various parts such as body panels, frames, and chassis. These coils provide the necessary strength and durability required for automotive applications, ensuring the safety and performance of vehicles.

Send your message to us

Prime Hot Dipped Galvanized Steel Coil Made in China DX51Grade D

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords