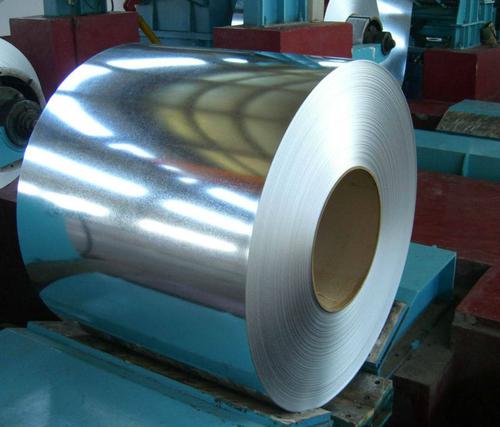

Hot dipped Galvanized Steel Coil Made in China

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

HOT DIP GALVANIZED STEEL COIL

Specification:0.3mm*1000mm*c

Steel Grade & Standard: ASTM A653

Zinc Coating Mass:Z180 Spangle:Zero Spangle

Surface Treatment: non-chromate, oiled

Coil ID:508mm Coil Weight:6-10MT

Package Type:EYE TO SIDE

Thickness Tolerance:+/-0.02mm Width Tolerance:+/-5mm

Zinc Coating Tolerance:-/+10g/m2

- Q: What is the role of steel coils in the production of industrial machinery?

- Steel coils play a crucial role in the production of industrial machinery as they are used as raw material for manufacturing various components and parts. These coils are typically cut, shaped, and formed into desired shapes and sizes to create structural frames, panels, gears, shafts, and other vital elements of machinery. The high strength and durability of steel make it an ideal choice for withstanding heavy loads, vibrations, and harsh operating conditions, ensuring the reliability and longevity of industrial machinery.

- Q: What are the factors to consider when selecting steel coils for a specific application?

- When selecting steel coils for a specific application, there are several factors that need to be considered. These factors include the type of application, the required strength and durability, the desired aesthetic appearance, the budget, and any specific industry standards or regulations that need to be met. Firstly, it is important to determine the type of application for which the steel coils will be used. Different applications may require different types of steel with varying properties. For example, if the coils will be used in structural construction, high-strength steel with excellent structural integrity may be required. On the other hand, if the coils will be used in automotive manufacturing, steel with good formability and weldability may be more suitable. The required strength and durability is another crucial factor to consider. This includes factors such as the load-bearing capacity, resistance to corrosion, and ability to withstand extreme temperatures or environmental conditions. The steel coils must be able to withstand the specific stresses and strains that will be placed upon them in the intended application. The desired aesthetic appearance is also important, especially in applications where the steel coils will be visible. Factors such as the surface finish, color, and texture of the steel coils may need to be considered. This is particularly relevant in industries such as architecture or interior design, where the visual appeal of the steel is a key consideration. Budgetary constraints should also be taken into account when selecting steel coils. Different grades and types of steel can vary significantly in price. It is important to find a balance between the desired properties and the available budget. Sometimes, it may be necessary to compromise on certain factors in order to meet budgetary constraints. Lastly, any specific industry standards or regulations should be considered when selecting steel coils. Certain industries, such as aerospace or automotive, may have strict requirements for the materials used in their products. In such cases, it is crucial to ensure that the selected steel coils meet all necessary standards and regulations. In conclusion, when selecting steel coils for a specific application, factors such as the type of application, required strength and durability, desired aesthetic appearance, budget, and industry standards or regulations should all be carefully considered. By taking these factors into account, one can make an informed decision and choose the most suitable steel coils for their specific application.

- Q: How are steel coils used in the production of industrial storage tanks?

- Industrial storage tanks commonly utilize steel coils due to their superior strength and durability. These coils are typically crafted from high-quality steel that is rolled into a coil shape, enabling convenient transportation and handling. During the production process, steel coils are initially uncoiled and flattened to create steel sheets. These sheets are then cut and formed into the desired shape and size for the storage tank. The steel sheets are joined together through welding or bolting to construct the tank's body, which is designed to endure high pressure and heavy loads. The utilization of steel coils in the production of industrial storage tanks offers numerous benefits. Firstly, the strength and durability of steel ensure that the tanks can withstand harsh conditions and resist corrosion. This is particularly vital for storage tanks containing corrosive substances or exposed to severe environments. Moreover, the flexibility of steel coils permits customization of the tank's design and size. This is especially advantageous in industries with varying storage requirements, like the oil and gas sector. Steel coils can be effortlessly cut and molded into diverse shapes and sizes, facilitating the creation of storage tanks tailored to specific storage needs. Furthermore, steel coils are easily transportable and storable, making them a cost-effective choice for industrial storage tank production. The coils can be efficiently transported to the manufacturing facility, reducing transportation costs and logistical complexities. In conclusion, steel coils play a crucial role in the production of industrial storage tanks by providing strength, durability, and customization options. Their usage guarantees the safe storage and protection of various substances, rendering them indispensable in a wide range of industries.

- Q: I'm trying to buy a Survival,tactical knife but don't know what steel is better

- Vanadium Steel Knives

- Q: is cold roll or hot roll mill roller is cast steel? or cast iron?

- another name is Grey iron, come from groups of ferrous alloys

- Q: LIke a steel building conversion into a residental building??? Thanks.

- Right here. Steel Homes, Steel House, Steel Buildings, Steel Home Plans, ... Steel Homes, Steel House, Steel Buildings, Steel Home Plans, Steel Houses, ... Steel Homes and Buildings · Steel Office Buildings and Construction sites ... www.karmod.eu/steel-structures - 18k - Similar pages www.karmod.eu/steel-structures steel buildings metal buildings modular homes steel building ... ... log homes photographs, log homes construction, sales agents, log homes financing, ... Easy online pricing

- Q: What is the shelf life of steel coils?

- The shelf life of steel coils is indefinite if they are stored properly. Steel coils are known for their durability and long-lasting nature, making them suitable for extended storage periods without any degradation in quality. However, it is important to store them in a dry and well-ventilated area, away from moisture and corrosive substances to prevent any potential damage.

- Q: What are the advantages of using pre-painted steel coils?

- There are several advantages to using pre-painted steel coils. Firstly, pre-painted steel coils have a protective coating applied during the manufacturing process, which makes them resistant to corrosion and increases their lifespan. Additionally, the pre-painted coating provides a smooth and aesthetically appealing finish, eliminating the need for further painting or finishing. This saves time and money on additional coatings or treatments. Moreover, pre-painted steel coils are available in a wide range of colors and finishes, allowing for greater design flexibility and customization. Lastly, pre-painted steel coils are easy to install, lightweight, and have excellent durability, making them an ideal choice for various applications in construction, automotive, and other industries.

- Q: What are the factors that affect the quality of steel coils?

- The quality of steel coils can be influenced by various factors. To begin with, the composition of the steel itself plays a vital role in determining its quality. Impurities like sulfur or phosphorus can have a negative impact on the strength, durability, and overall performance of the steel. Additionally, the quality of the steel is affected by its carbon content, alloying elements, and heat treatment. Furthermore, the quality of the steel coils is greatly affected by the manufacturing process and techniques utilized during production. Factors such as the cleanliness of the production environment, the precision of the rolling and cooling processes, and the control of temperature and pressure throughout manufacturing all contribute to the final quality of the coils. Additionally, the surface quality of the steel coils is a crucial factor. Any defects or imperfections on the surface, such as scratches, dents, or corrosion, can compromise the integrity and functionality of the coils. It is essential to handle, store, and transport the coils properly to maintain their surface quality. Moreover, the mechanical properties of the steel coils, including tensile strength, yield strength, and elongation, are essential indicators of their quality. These properties depend on various factors, such as the type of steel, its thickness, and the processing conditions. Lastly, external factors such as environmental conditions, like humidity and temperature, can affect the quality of steel coils. Exposure to moisture or extreme temperatures can lead to corrosion or other forms of degradation, impacting the overall quality and lifespan of the coils. In conclusion, the quality of steel coils is influenced by several factors, encompassing the composition of the steel, the manufacturing process, surface quality, mechanical properties, and external environmental conditions. It is crucial to carefully control and monitor these factors to produce high-quality steel coils that meet the desired specifications and standards.

- Q: How are steel coils used in the automotive stamping process?

- Steel coils are a critical component in the automotive stamping process. These coils are essentially large rolls of steel that are unwound and fed into stamping machines. The coils are typically made of high-quality steel and come in various thicknesses and widths to meet the specific requirements of different automotive parts. During the stamping process, the steel coils are fed through a series of dies and presses that shape and form the metal into the desired automotive components. The coils are unwound and passed through a straightener to remove any bends or twists, ensuring a smooth and consistent feed into the stamping machine. The stamping machine then uses a combination of hydraulic or mechanical force to press the steel coil against a die, which is a specially designed mold that gives shape to the metal. The die is often made of hardened steel to withstand the pressure and provide accurate and repeatable results. The steel coil is fed into the stamping machine at a high speed, and as it passes through the die, the metal is formed into various automotive parts such as body panels, doors, hoods, fenders, and other structural components. The stamping process allows for high precision and consistency in producing these parts, ensuring they meet the required specifications and tolerances. Once the metal is formed, it may undergo additional processes such as trimming, piercing, or bending to achieve the final shape. These processes are often performed in subsequent stamping stations or by using progressive dies that combine multiple operations into a single pass. Overall, steel coils play a vital role in the automotive stamping process as they provide the raw material required to produce various components. The use of steel ensures the necessary strength, durability, and safety of the automotive parts while maintaining cost-effectiveness and mass production capabilities.

Send your message to us

Hot dipped Galvanized Steel Coil Made in China

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords