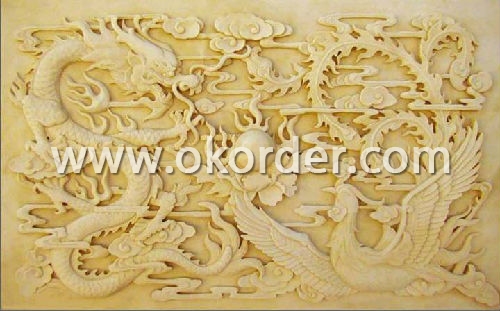

Pediment Ornament Mould For Wall Decoration

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 Sets set

- Supply Capability:

- 5000000 Sets set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction Of Pediment Ornament Mould For Wall Decoration:

GRC material has excellent constructive performance in history of building construction. With high strength and good nature, it is fireproof, mildew and worm resistant, moisture proof, and sound and heat insulated. It can be processed by nailing, adhering and patching, thus it is easy and convenient in construction.

Description Of Pediment Ornament Mould For Wall Decoration:

High strengh

Corrosion resistance, anti-frost and waterproof

Natural and hand crafted

Durable

Component Of Pediment Ornament Mould For Wall Decoration:

Glass Fibre Reinforced Cement(Cement, Alkali Resistant Glass Fibre / protofilament), short for GRC/GFRC

Advantage Of Pediment Ornament Mould For Wall Decoration:

Strong, Tensile-strength: 1800 Mpa, twice to triple as much as that of steel fibre.

S. G.: 2.7

Durability: Over 10 years

High heat-resistant: Its softening point is about 860

Anti-frost, waterproof&fireproof, mildew&worm and corrosion resistance

UV-protection&environment friendly

Maintenance free

Customer designs are available. Our products are very popular with domestic and abroad market. We have built a steady and long-term cooperation relationships with Chinese top 20 real estate companies and our products are exported to the Middle East, Western Europe, North America, South Africa and other countries and regions.

- Q: If the building a total of 6 and a half, almost 7 layers, what is the use of building materials is better? Durable, such as how much steel, what type of cement, how to match? What drain? What wire? What should you pay attention to? Please provide me with a list of building materials and the precautions that should be taken from the building. Anxious!

- The following is a brief description, it is recommended to find a nearby project to see if there is no intention of the drawings COPY a change (or on the infringing) wall pillar C30 beam C35 reinforced general beam of 18 to 20 of the three steel plate 12 spacing 200 enough for the stirrups 6 PCT can be spaced 200 encryption area to see their own bricklaying plaster general composite Portland cement 32

- Q: what r the raw materials used to make cement?

- Lime, sand and water.

- Q: Here in San Antonio's far NE side there is about 3 major cement factorys/parks. Next to all 3 there is big lakes/ponds. Why?

- they need water to make cement

- Q: Which is stronger PVC cement or Contact cement?

- Depends what you are using it on. PVC is designed to melt and weld two pieces of PVC. Contact cement won't work with PVC. Similarly contact cement is designed to laminate two surfaces like plastic or wood that will not be subjected to water or water pressure as found in an irrigation system fitted with PVC pipes. PVC cement will not work for that. Since you didn't indicate WHAT you are trying to bond, choose accordingly.

- Q: I am taking a chemistry course and i am wondering what purpose quot;PVC Resinquot; serves and how it achieves that purpose?

- How Does Pvc Glue Work

- Q: Why cement, red brick, steel bars in the second half of these building materials will be relative to the first half prices

- First, the first half of the year in the rainy season, is not conducive to the construction, and most of the first half of the busy production, construction will be less; secondly, the summer power for the Gonggong grubs seaweed cut Wei public should be tense will also adversely affect the production of building materials

- Q: is it eaiser to hire somebody?

- That would depend on the size of the job. If it is a small job, the sackcrete would serve you well. Make a form where you want the conrete, put the sackcrete in a five gallon bucket, add water and stir with a shovel. A wheelbarrow, is another option, especially if you have to move any distance from the water source. As it dries, work the cement to the finish that you want. If it starts to dry too fast, add a small amount of water.

- Q: Why do people call a concrete mixer a cement mixer?

- Because they don't really know what they are talking about, that's why. However, it's not really their fault. The two words have become synonymous over the years. It's similar to the name Kleenex. Kleenex is a brand name, not the name of a product. The product is a facial tissue, but when you want to blow your nose you ask for a Kleenex even though it may not be the Kleenex brand. The same thing happened with cement and concrete. Technically speaking, cement is the powder that you add to sand, gravel, and water to get concrete. The product is concrete, but the ingredient that makes the product is cement. People have been confusing the two for years.

- Q: Did anyone die in cement at hover dam?

- Isn't that where Jimmy Hoffa was tossed in? ;)

- Q: I am wanting to add a cement patio on to my house and in order to build a $6000 patio, I have to pay a $5000 road bond to the village does that make sense

- Is this 'bond' a form of insurance? It sounds as if the roads in your area are less than adequate to support heavy trucks and the village is trying to protect themselves from the expense of repairing the road. You don't say where in the world you are so this may loose something in the translation.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2006 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | 20.00% North America 15.00% South America 15.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Lianyungang Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 150,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Pediment Ornament Mould For Wall Decoration

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 Sets set

- Supply Capability:

- 5000000 Sets set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords