High-Quality FRP Roofing Panel for Corrosion-Resistant Roofing Tile and Balcony Roof Covering

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m

- Supply Capability:

- 40000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

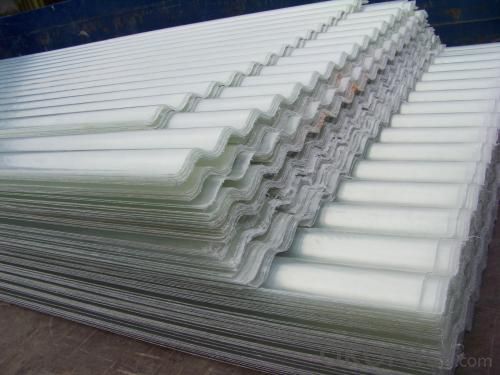

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

Besides, it could also applied as the roof of the constructions

FEATURES

1) The fiberglass content of new generation greenhouse panel has been improved by 18.3%.

2) Weather resistant and Self-clean ability.

3) Excellent yellowness resistance.

4) Strong impact resistant and low bending rate.

5)Withstand extreme temperature from -38 degree to +110 degree for a long time

6) Aging resistant: specified F4 film added on surface and gel coat makes it endurable for long.

7) More strengthened, safer, cleaner and more economical greenhouse panel.

8) Mainly serve the big factory, warehouse, super markets and other steel-structured project.

SPECIFICATION

Name | FRP Roofing |

Material | Fiberglass |

Width | 880mm/1050mm |

Effective width | 800mm/960mm |

Wave length | 160mm |

Wave height | 30mm |

Pitch | 220mm |

Thickness | 3/2.5mm |

Length | Customized but must be a multiple of wave pitch |

Color | Purplish Red, Brick Red, Grey, Green, Blue or customized |

Application | House, villa, pavilions, industrial plants, large warehouses, supermarkets, stadiums etc |

MOQ | 1000 Square meter |

PICTURES

- Q: Do FRP roofing panels require any specific safety measures during installation?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels do require specific safety measures during installation. Here are some important safety measures that should be followed: 1. Personal Protective Equipment (PPE): Installers should wear appropriate PPE such as safety glasses, gloves, and non-slip footwear. This will protect them from potential hazards such as sharp edges or falling debris. 2. Safe Work Environment: Before starting the installation, ensure that the work area is clear of any obstructions or tripping hazards. It is important to maintain good housekeeping practices to minimize the risk of accidents. 3. Fall Protection: If the installation requires working at heights, fall protection measures such as harnesses, guardrails, or safety nets should be implemented. Installers should be properly trained in the use of fall protection equipment. 4. Proper Lifting Techniques: FRP roofing panels can be heavy, so it is important to use proper lifting techniques to avoid strains or injuries. Team lifting or using mechanical lifting devices may be necessary depending on the weight and size of the panels. 5. Power and Tool Safety: If power tools are used during installation, they should be operated according to the manufacturer's instructions and only by trained personnel. Electrical safety precautions, such as using grounded tools and avoiding wet conditions, should also be followed. 6. Weather Conditions: Weather conditions can impact the safety of installation, especially when working at heights. Installers should be aware of potential hazards such as strong winds, rain, or lightning and take appropriate precautions, such as rescheduling the work if necessary. 7. Training and Supervision: It is essential that all installers are properly trained in the installation techniques and safety measures specific to FRP roofing panels. Regular supervision and communication about safety practices can help prevent accidents and ensure a safe working environment. By following these safety measures, the risk of accidents or injuries during the installation of FRP roofing panels can be significantly reduced, ensuring the safety of the installers and the overall success of the project.

- Q: Do FRP roofing panels have any specific building code approvals?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels typically have specific building code approvals. These approvals ensure that the panels meet the required safety and performance standards set by building codes. It is important to check with local building authorities or consult the manufacturer's specifications to confirm the specific building code approvals for FRP roofing panels in a particular area.

- Q: Are FRP roofing panels prone to warping from constant sunlight exposure?

- Due to their specific design, FRP roofing panels are highly resistant to warping caused by continuous exposure to sunlight. This is because they are engineered to withstand harsh weather conditions, including prolonged sunlight exposure. The combination of fiberglass and plastic resin in the composition of FRP panels ensures exceptional durability and UV resistance. The high strength and dimensional stability of FRP panels can be attributed to the presence of fiberglass. This makes them less likely to warp even when exposed to sunlight for long periods of time. Moreover, the plastic resin acts as a protective layer, safeguarding the fiberglass from the harmful effects of UV rays. The combination of these materials ensures that FRP roofing panels maintain their structural integrity and appearance over time. It should be noted, however, that proper installation and maintenance are crucial in order to prolong the lifespan of FRP roofing panels. Adhering to the manufacturer's installation guidelines, which include appropriate fastening and sealing techniques, is essential to prevent any potential warping issues. Additionally, regular cleaning and inspection can help identify and address any maintenance requirements, thus ensuring that the panels remain in optimal condition. To sum up, FRP roofing panels are highly resistant to warping caused by continuous sunlight exposure. This is due to their composition of fiberglass and plastic resin, which provides exceptional durability and UV resistance. Nevertheless, it is important to follow proper installation and maintenance practices to ensure the longevity and performance of FRP roofing panels.

- Q: Can FRP roofing panels be used in high-temperature environments?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used in high-temperature environments. These panels are designed to be heat-resistant and can withstand elevated temperatures without warping or deforming. They are often used in industrial settings, such as chemical plants or factories, where high temperatures are common. However, it is important to consider the specific temperature limits and recommendations provided by the manufacturer to ensure the panels are suitable for the intended high-temperature application.

- Q: Can FRP roofing panels be used for skylight domes?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can definitely be used for skylight domes. FRP is a durable and lightweight material that is commonly used in construction for its strength and resistance to weathering. It can be molded into various shapes, including domes, making it an ideal choice for skylights. FRP panels offer excellent light transmission, allowing natural light to enter the space while maintaining insulation and energy efficiency. Additionally, FRP is highly resistant to UV radiation and can withstand extreme temperatures, making it a reliable option for skylight domes. Overall, FRP roofing panels provide a cost-effective and long-lasting solution for skylights, offering both functionality and aesthetic appeal.

- Q: Are FRP roofing panels prone to discoloration?

- Yes, FRP roofing panels are prone to discoloration over time due to exposure to UV rays and other environmental factors. This can result in a faded or yellowish appearance, affecting the aesthetic appeal of the panels. However, regular maintenance and the application of protective coatings can help prevent or minimize discoloration.

- Q: Can FRP roofing panels be used for storage buildings?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for storage buildings. FRP roofing panels are lightweight, durable, and resistant to various weather conditions, making them suitable for use in storage buildings. They provide excellent protection against UV rays, corrosion, and impact, ensuring that the contents inside the storage building remain safe and secure. Additionally, FRP roofing panels are easy to install, cost-effective, and low maintenance, making them a popular choice for storage buildings.

- Q: Can FRP roofing panels be used in skylights?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used in skylights. FRP panels are lightweight, durable, and resistant to UV rays, making them suitable for skylight applications. They provide excellent light transmission, insulation, and can be custom-made to fit various skylight sizes and shapes.

- Q: Can FRP roofing panels be used for outdoor signage structures?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for outdoor signage structures. FRP panels are known for their durability, lightweight nature, and resistance to various weather conditions. These qualities make them a suitable choice for outdoor signage structures that require long-term reliability and protection from elements such as rain, UV rays, and wind. FRP roofing panels are commonly used in various outdoor applications, including commercial and industrial buildings, agricultural structures, and even transportation vehicles. Their resistance to corrosion and fading ensures that the signage will remain intact and vibrant over time, even when exposed to harsh outdoor conditions. Additionally, FRP panels offer flexibility in terms of design options. They can be easily customized to accommodate various shapes, sizes, and colors, allowing for creative and eye-catching signage structures. The lightweight nature of FRP panels also makes them easy to handle and install, reducing the overall installation time and effort. Overall, FRP roofing panels provide a reliable and cost-effective solution for outdoor signage structures. Their durability, weather resistance, and customizable design options make them a suitable choice for businesses and organizations looking to create impactful and long-lasting signage.

- Q: Are FRP roofing panels resistant to vandalism or graffiti?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are typically resistant to vandalism or graffiti due to their durable and non-porous surface.

Send your message to us

High-Quality FRP Roofing Panel for Corrosion-Resistant Roofing Tile and Balcony Roof Covering

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m

- Supply Capability:

- 40000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords