Heat Resistant Aluminium Foil Laminated Fiberglass Fabric

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:The combination of laminating an aluminum metallic/film heat shield to a layer of protective fiberglass insulation protects personnel or equipment by reflecting radiant heat. The fabric have advantages of smooth and flat surface, high resistant, good tensile strength, airtight, watertight, good sealed performance, strong weather-ability, etc.

Features: High Reflectivity, Waterproof, Fire Resistant, Heat Resistant

Application: Thermal Insulation Jackets, Cover, Blanket, Mattress, Pad,Heat Shields, Thermal Barrier, Industrial Safety Apparel

PRICE: USD3.2 per square meter

UNIT: square meter

MOQ: 500 square meters

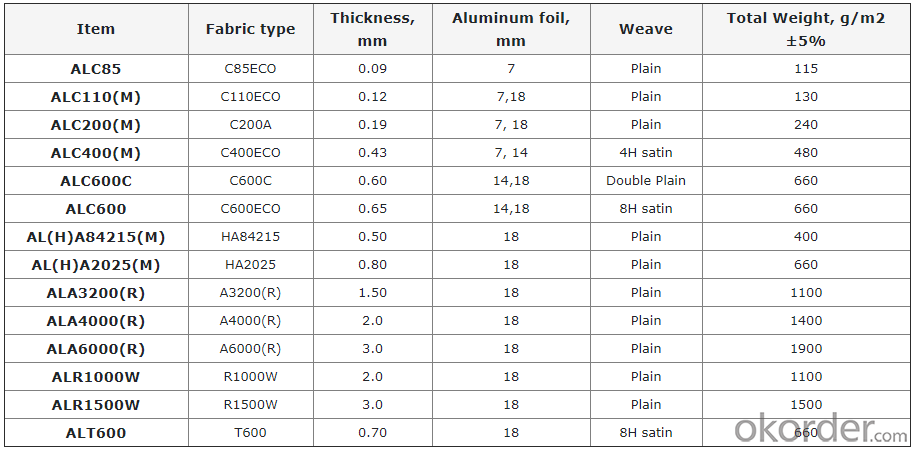

Weight: 220gsm-1200gsm or customized

Width: 1m-2m or customized

Yarn Type: E-glass

Standing temperature:550℃

Product name: Aluminium Foil laminated fiberglass fabric

Coating/Finish/Surface Treatment: Aluminium Foil laminated

Roll length: 50 meter or customized

Color: silver grey

Weave Type: twill woven

Alkali content: alkali free

Processing service: cutting

Material: fiberglass fabric, Aluminium foil

Thickness: 0.2mm to 1.7mm or customized

Size: can be customized

Supply ability: 300000 meters per month

Packaging: Aluminium foil laminated fiberglass fabric rolls packed in cartons loaded on pallets or according to customers' requirements.

Lead time: 7-30 days

- Q: Is fiberglass fabric resistant to oil and grease?

- Yes, fiberglass fabric is generally resistant to oil and grease. Fiberglass has excellent chemical resistance properties, making it highly resistant to a wide range of oils and greases. This resistance is due to the non-reactive nature of fiberglass, which prevents the fabric from being degraded or damaged by contact with oil and grease. Additionally, fiberglass fabric is also resistant to many other chemicals, including acids, alkalis, and solvents, making it a versatile material in various industries where resistance to oil and grease is required. However, it is important to note that the level of resistance may vary depending on the specific type and quality of fiberglass fabric used. It is always recommended to consult the manufacturer or supplier for specific information on the resistance capabilities of the fiberglass fabric in question.

- Q: Can fiberglass fabrics be recycled or repurposed?

- Fiberglass fabrics possess the ability to be recycled or repurposed. This highly adaptable material can be disassembled and utilized in multiple ways. A common practice for recycling fiberglass involves grinding it into powder and incorporating it as a filler in composite products like concrete, insulation, or even new fiberglass items. This procedure not only reduces waste but also enables the reuse of fiberglass materials. Additionally, fiberglass fabrics may be repurposed by cutting them into smaller segments and employing them as insulation or reinforcement in other substances. These repurposed fabrics find applicability in various fields such as automotive components, boat repairs, or even artistic and craft projects. Ultimately, the recycling and repurposing of fiberglass fabrics contribute to waste minimization and optimal utilization of this resilient material.

- Q: Can fiberglass fabric be used for insulation in aerospace applications?

- Yes, fiberglass fabric can be used for insulation in aerospace applications. It is a common choice due to its excellent thermal resistance, lightweight nature, and resistance to high temperatures. Additionally, fiberglass fabric provides good sound insulation, making it suitable for aerospace environments.

- Q: What is the advantage of coating waterproof layer with matrix reinforcing material?

- Since the matrix reinforcement material to absorb the paint, retained a part of glue, not to lower flow, but also increased the flow of glue down resistance, play the role of carrier. Therefore, the slope of the roof and facade in the film overlay non-woven fabric or fiberglass cloth, can play a solid glue, adhesive effect, especially some long curing time, low viscosity coating paving a layer of cloth, to ensure the construction quality of the film.

- Q: Are fiberglass fabrics easy to sew or work with?

- Yes, fiberglass fabrics are generally easy to sew or work with. They have a smooth texture and do not fray easily, making them manageable for sewing projects. Additionally, their lightweight nature allows for flexibility and ease of handling. However, it is important to take necessary precautions such as wearing protective gear and ensuring proper ventilation when working with fiberglass fabrics due to their potential health hazards.

- Q: Problems in making FRP models and models

- The higher precision is the three-dimensional engraving machine, but this machine can generally do very limited volume, can not do big things. This engraving machine usually needs to be polished again after making the bottom mold

- Q: Is fiberglass fabric resistant to bacteria and fungi?

- Yes, fiberglass fabric is generally resistant to bacteria and fungi. Fiberglass is a non-porous material that does not provide a suitable environment for bacterial or fungal growth. Additionally, fiberglass fabric is often treated with special coatings or finishes that enhance its resistance to these microorganisms. These treatments inhibit the growth of bacteria and fungi, making fiberglass fabric a good choice for applications where hygiene is important, such as in medical or food processing industries. However, it is important to note that the resistance may vary depending on the specific type of fiberglass fabric and the presence of any additional treatments or coatings.

- Q: Are fiberglass fabrics suitable for use in the marine industry?

- The marine industry finds fiberglass fabrics to be highly appropriate. Fiberglass, a sturdy and adaptable material, offers numerous advantages for marine applications. To begin with, fiberglass fabrics possess exceptional resistance to water, chemicals, and UV radiation. This makes them well-suited for enduring prolonged exposure to the harsh marine environment. The fabric remains intact and unaffected when subjected to saltwater, sunlight, or other corrosive elements commonly found in the marine industry. Additionally, fiberglass fabrics boast high tensile strength while being extremely lightweight. This makes them ideal for boat hulls, decks, and other structural components. The strength-to-weight ratio of fiberglass fabrics allows for the construction of sturdy yet lightweight marine vessels, resulting in improved fuel efficiency and performance. Moreover, fiberglass fabrics are known for their excellent thermal insulation properties. This is particularly important in the marine industry. The insulation provided by fiberglass fabrics helps regulate temperature, ensuring that the interior of boats or ships stays cool in hot weather and warm in cold weather. This is beneficial for maintaining comfort and reducing energy consumption onboard. Furthermore, fiberglass fabrics are easily manipulated and can be molded into various shapes and sizes. This allows for the creation of customized marine components. They can be used to reinforce or repair existing structures, as well as for the construction of new boats or ships. In conclusion, fiberglass fabrics are highly suitable for use in the marine industry due to their durability, resistance to harsh elements, high strength-to-weight ratio, thermal insulation properties, and versatility. Their wide range of applications and excellent performance make them a preferred choice for boat builders, shipyards, and other marine industry professionals.

- Q: Glass fiber cloth can be made into handbags, requirements of high temperature 680 degrees or more

- There are many kinds of glass fiber fabric, you can choose as long as you choose, such as medium and high strength glass fiber cloth".

- Q: What is fiberglass sound absorption board?

- Glass fiber sound absorbing board, referred to as glass wool or soundproof cotton

Send your message to us

Heat Resistant Aluminium Foil Laminated Fiberglass Fabric

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords