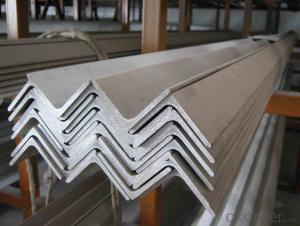

high quality equal angle ATM A36

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ROUND BAR Details:

| Minimum Order Quantity: | | Unit: | m.t. | Loading Port: | |

| Supply Ability: | | Payment Terms: | | Package: | wire bundle |

Product Description:

Specifications of Wire Rod Q235:

Steel Grade: Q235, Standard: GB Diameter: 5.5mm, 6.5mm, 7mm,8mm,9mm,10mm,12mm,14mm

Diameter Tolerance:±0.3mm 6.5mm can be drawing into 2mm/8.0mm can be drawing into 3mm

Brand Name: N-RIVER Place of Origin: Hebei, China Mainland Application: construction, building etc

Chemical Composition:

Please kindly find our chemistry of our material based on Q235 as below for your information

Trademark | Rank | Chemical composition (quality score) % | | ||||

C | Si | Mn | S | P | | ||

| | |||||||

| ≤ |

| ≤ | ≤ | | ||

Q235 | A | 0.14-0.22 | 0.30 | 0.30-0.65 | 0.050 | 0.045 | |

Q235 | B | 0.12-0.20 | 0.30 | 0.30-0.70 | 0.045 | 0.045 | |

Trademark | Rank | Pulling Test | | ||||

Bend PointΔs/Mpa | Tensile Strength | Elongation Ratioδ5% | | ||||

| | |||||||

Thickness (Diameter) /MM | Thickness (Diameter) /MM | | |||||

≤16 | 16-40 | | ≤16 | 16-40 | | ||

≥ | | ≥ | | ||||

Q235 | A | 235 | 225 | 375-500 | 26 | 25 | |

Q235 | B | 235 | 225 | 375-500 | 26 | 25 | |

Usage and Applications of Wire Rod Q235:

After hot-rolled the products shaped into coil and delivery as finished product, including round, square, rectangular, hexagonal and so on. Since most of the products are round, it is generally called wire rod. Carbon steel wire rod is widely used in construction and manufacturing. Carbon steel wire rod is mainly used for reinforcement of reinforced concrete and welded structure or reprocessed (roberts , nail, etc.) materials, especially used to produce wire drawing, welding electrode, nails, spring, electronic, precise machinery parts and so on.

Packaging & Delivery of Wire Rod Q235:

Packaging Detail: products are packed in coil and then shipped by container or bulk vessel

Each coil weight: 2-3MT

Delivery Detail: within 45 days after received deposit or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: FOB, CFR, CIF

- Q: Can steel angles be used in residential construction?

- Yes, steel angles can be used in residential construction. Steel angles are versatile structural elements that are commonly used in various construction applications, including residential buildings. They are often used for framing, reinforcing, and providing structural support in walls, roofs, and floors. Steel angles are preferred in residential construction due to their strength, durability, and ability to withstand heavy loads. They can be easily welded, bolted, or screwed into place, making them suitable for a wide range of construction projects. Additionally, steel angles can be galvanized or coated to enhance their resistance to corrosion, ensuring their longevity. Overall, steel angles are a reliable and cost-effective choice for residential construction.

- Q: What are the different methods of corrosion protection for steel angles?

- Steel angles can be protected from corrosion through various methods, each having its own advantages and disadvantages. 1. Protective coatings are commonly used to safeguard steel angles. These coatings include paint, epoxy, and galvanization. Paint creates a barrier that prevents moisture and oxygen from reaching the steel surface. Epoxy coatings offer a more robust layer, providing enhanced corrosion protection. Galvanization involves applying a zinc layer to act as sacrificial protection, corroding before the steel. 2. Cathodic Protection utilizes an external electrical current to safeguard steel angles. By connecting the steel to a more easily corroded metal, such as zinc or magnesium, and applying direct current, the less noble metal corrodes instead of the steel. This method is beneficial in marine or underground environments. 3. Alloying can also protect steel angles from corrosion. By adding small amounts of metals like chromium or nickel to the steel composition, the resulting alloy forms a protective oxide layer on the surface, preventing further corrosion. Stainless steel is an excellent example of an alloy with high corrosion resistance. 4. Barrier Films create a physical barrier on the steel surface to prevent corrosion. This method involves applying films like polyethylene or PVC, which block moisture and oxygen from reaching the steel. It is commonly used in environments with harsh conditions or chemicals. 5. Environmental Control is another way to prevent corrosion. By controlling the environment in which the steel angles are placed, exposure to moisture, humidity, and corrosive chemicals can be minimized. Proper ventilation, regular cleaning, and maintaining a dry environment contribute to corrosion prevention. It is important to consider several factors, such as the specific application, environmental conditions, and budget constraints, to determine the most suitable corrosion protection method for steel angles. Consulting corrosion experts or engineers is recommended for a tailored approach.

- Q: What are the different finishes available for steel angles?

- There are several different finishes available for steel angles, depending on the desired look and level of protection required. One common finish is hot-dip galvanizing, which involves immersing the steel angle in a bath of molten zinc to create a corrosion-resistant coating. This finish provides excellent protection against rust and is commonly used in outdoor applications or in environments with high humidity or exposure to chemicals. Another option is powder coating, which involves applying a dry powder to the steel angle and then baking it in an oven to create a hard, durable finish. Powder coatings come in a wide range of colors and textures, allowing for customization to match specific design requirements. Additionally, powder coating provides good corrosion resistance and is commonly used in architectural and decorative applications. For a more natural look, steel angles can be left untreated or given a mill finish. Mill finish refers to the surface finish that is produced during the manufacturing process, which typically has a smooth, slightly reflective appearance. This finish is often used in structural applications where aesthetics are not a primary concern. Lastly, steel angles can also be painted or coated with an enamel finish. This involves applying a liquid paint or enamel coating to the surface, which provides protection against rust and can also enhance the appearance of the steel angle. Painted finishes come in a wide range of colors and can be customized to match specific design requirements. Overall, the choice of finish for steel angles depends on factors such as the desired level of corrosion resistance, aesthetic preferences, and the specific application or environment in which the steel angles will be used.

- Q: What does L50*4 angle mean in CAD?

- In L50*4, 50 represents the side length of 50mm, and 4 represents the thickness of 4mm.Figures similar to those in H500*200*6*8 represent the overall dimensions of the material.

- Q: How do you calculate the radius of gyration for a steel angle?

- To calculate the radius of gyration for a steel angle, you need to take into account the dimensions and properties of the angle. The radius of gyration is a measure of how the mass of an object is distributed around its axis of rotation. It tells you how far the mass is located from the axis, which influences the object's rotational stability. The formula to calculate the radius of gyration for a steel angle is: k = √(I / A) Where: - k is the radius of gyration - I is the moment of inertia of the section about its axis of rotation - A is the cross-sectional area of the steel angle The moment of inertia (I) represents the resistance of an object to changes in its rotational motion. It depends on the shape and size of the object. The cross-sectional area (A) of the steel angle is the total area enclosed by its shape. To calculate the moment of inertia, you can use the formula specific to the shape of the steel angle. For example, if the angle has equal flanges, you can use the formula: I = (b1 * h1³ + b2 * h2³) / 12 Where: - b1 and b2 are the widths of the flanges of the angle - h1 and h2 are the thicknesses of the flanges of the angle Once you have calculated the moment of inertia and the cross-sectional area, you can substitute these values into the radius of gyration formula to find the radius of gyration (k). It is important to note that the radius of gyration is a theoretical value that assumes the object is a perfect, homogeneous shape. In reality, the actual behavior and stability of a steel angle can be influenced by factors such as material imperfections, loading conditions, and connection details. Therefore, it is always recommended to consult engineering resources or professionals for accurate and specific calculations related to structural design and analysis.

- Q: How do steel angles contribute to the overall earthquake resistance of a structure?

- Steel angles contribute to the overall earthquake resistance of a structure by providing stability and strength. These structural components are often used to reinforce corners and connections, distributing and transferring the seismic forces throughout the building. Their rigid and load-bearing properties help to resist bending, twisting, and shearing, enhancing the structural integrity and reducing the risk of collapse during an earthquake.

- Q: Can steel angles be galvanized or coated for corrosion resistance?

- Yes, steel angles can be galvanized or coated for corrosion resistance. Galvanizing is a common method used to protect steel from corrosion by applying a layer of zinc to the surface. This process creates a barrier between the steel and the external environment, preventing the formation of rust. Coating steel angles with corrosion-resistant materials such as epoxy or powder coatings is another option to enhance their resistance to corrosion. These coatings act as a protective layer, preventing moisture and other corrosive elements from reaching the steel surface. By applying galvanization or coatings, steel angles can significantly increase their lifespan and maintain their structural integrity in corrosive environments.

- Q: Are steel angles suitable for outdoor staircases?

- Outdoor staircases can indeed be made with steel angles, as steel possesses qualities such as durability, strength, and resistance to weathering. These attributes make steel an ideal option for outdoor purposes. Steel angles, in particular, offer structural support and stability to staircases, enabling them to endure heavy loads and constant usage. Furthermore, these steel angles can be coated or painted to provide additional safeguarding against rust and corrosion, thereby extending their lifespan. In summary, utilizing steel angles for outdoor staircases presents a dependable and enduring solution.

- Q: Can steel angles be used as reinforcing bars in concrete structures?

- Yes, steel angles can be used as reinforcing bars in concrete structures. Steel angles are commonly used for this purpose due to their strength and durability. They provide additional strength to the concrete, preventing cracks and increasing the overall stability of the structure. Steel angles are typically embedded in the concrete to provide reinforcement in areas where additional support is required, such as in beams, columns, and slabs. They are commonly used in construction projects such as bridges, buildings, and other concrete structures.

- Q: What are the common methods of joining or connecting steel angles together?

- Common methods of joining or connecting steel angles together include welding, bolting, and using angle brackets or cleats.

Send your message to us

high quality equal angle ATM A36

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords