High Quality Deep Well Pump

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 35000台 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

high quality 2 cubic meter per hour 0.37kW Deep Well Pump

◊ APPLICATION

For water supply from wells or reservoirs.

For domestic use, for civil and industrial applications.

For garden use and irrigation.

◊ MOTOR AND PUMP

1. Rewindable motor

2. Equip with start control box or digital auto-control box

3. Pumps are designed by casing stressed

4. NEMA dimension standards

◊ OPERATING LIMITS

1. Maximum fluid temperature up to +40℃

2. Maximum sand content: 0.25%

3. Maximum immersion: 80m

4. Minimum well diameter: 4”

◊ FEATURES

1. CE certificate

2. 100% copper wire, automatic wiring

3. Cold-rolled silicon steel sheet, with high-speed punching, improve the efficiency and precision.

4. CNC precision automatic lathe for smoother shaft.

5. Strict tests include water test, outgas test and performance test, ect.

6. Anti-rust treatment castings and electrophoresis.

Material | |

Pump external casing | AISI 304 SS AISI 201 SS |

Delivery casing | Cast-Cu AISI 304 SS |

Suction lantern | Cast-Cu AISI 304 SS |

Diffuser | Plastic PC |

Impeller | Plastic POM |

Shaft | AISI 316 SS AISI 304 SS |

Shaft coupling | AISI 316 SS AISI 304 SS |

Wear ring | AISI 304 SS |

Motor external casing | AISI 304 SS AISI 201 SS |

Top chock | Cast-Cu Cast-iron |

Bottom support | AISI 304 SS |

Mechanical seal | Special seal for deep well (carbon-SIT/TC) |

Shaft | AISI 304 SS |

Bearing | NSK C&U |

Seal lubricant oil | Oil for food machinery and pharmaceutical use |

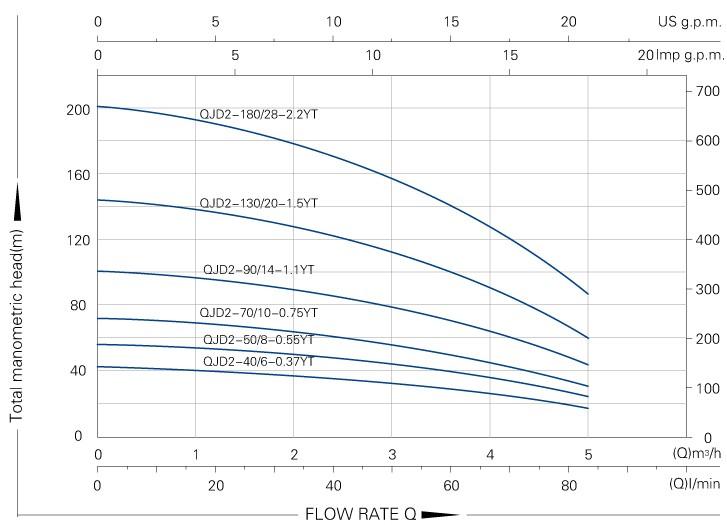

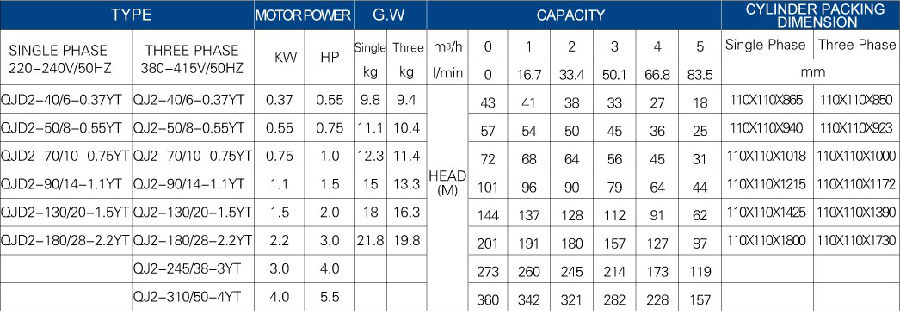

◊ TECHNICAL DATA

- Q: What is a water pump coupling device?

- Advantages of water pump coupling device:1. automatic coupling device, easy installation and maintenance. In the absence of automatic coupling device, fixed installation, such as water pump failure, maintenance personnel need to unscrew screws, lifting pumps for maintenance, or with other small pumps pumping water perfect maintenance,If the water is dirty, it is difficult for people to get down, when the inspection and repair encountered great difficulties. But it is equipped with GAK submersible sewage pumpAfter the automatic coupling device needs lifting, the person can directly lift the water pump without the need to screw the screw into the waterAfter graduation, down the guide rail, you can realize the sealing of water pump and pipeline, so as to make the pump run normally. Small sewage pumps are freeInstallation, large sewage pumps are generally equipped with automatic coupling device, automatic installation, installation and maintenance is very convenient.

- Q: How about the depreciation of vacuum pumps?

- (three) appliances, tools, furniture and so on related to the production and operation activities, for 5 years;(four) aircraft, trains, ships and other means of transport for 4 years;

- Q: 5 floor water pressure is too low, what kind of water pump is better?

- Installed pump flow, lift did not meet the requirements, this will need to re type selection, calculation;

- Q: What is the lift of diaphragm pump?

- Diaphragm pump lift is different from the centrifugal pump, refers to the diaphragm pump can raise the height of water, the unit is meters water column. Lift depends on the size of the outlet pressure, the pressure per kilogram is equivalent to 10 meters height

- Q: Why should I pump the pump before starting the centrifugal pump?

- Before the operation of the centrifugal pump, the pump must be filled with water, exhaust the air, before you start the operation. All centrifugal pumps should be handled this way, which is the centrifugal pump itself.The way of water diversion:1., in the centrifugal pump outlet increase water diversion pump (usually using vacuum pump), start the centrifugal pump before, start the vacuum pump, the centrifugal pump air into;2. increase the vacuum water tank before the intake of the centrifugal pump to meet the working conditions of the centrifugal pump;3. in the centrifugal pump inlet water increase valve, to meet the working conditions of centrifugal pump;4., if the water tank or water tank volume of water level is higher than the centrifugal pump position, the first operation of the front row empty, usually do not empty, you can use.

- Q: I want to know the concrete under 60 type pump performance, it is mainly the pump long spiral bored piles, such as the diameter of the pump, transportation distance, pumping height and so on, thank you!

- Maximum theoretical vertical transfer distance is m 270Maximum theoretical level conveying distance m 1200Distributing valve form S pipe valve (whole casting)

- Q: How many pumps does the 80cm tank use?

- For example, you are 80 cm tank, assuming you are 40 cm wide, the water surface is also 40 cm, then the final count by 80X40X40=128000 cubic centimeter, that is, 128000 ml.

- Q: Is the flow meter in front of the pump or after the pump?

- After the flowmeter is placed in the pump, it is better to add a pressure tank or a buffer tank, so that the flow meter will work better

- Q: How many concrete pump tube diameter

- The pump is generally divided into 125 and 150 two, the inner diameter is 125mm and 150mm. And the two kinds of each have high and low pressure points. Low pressure type type 125 pump for the pipeline diameter is phi 133,

- Q: What is an industrial water pump?

- The pump has the different uses, conveying different liquid medium, different flow rate, different lift range, therefore, its structure of course is not the same, the material is different, in general, can be divided into:1, urban water supply 2, sewage system 3, civil and construction systems 4, agricultural water conservancy system 5, power station system6. Chemical system 7, petroleum industry system 8, mine metallurgy system 9, light industry system 10, ship system

Send your message to us

High Quality Deep Well Pump

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 35000台 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches