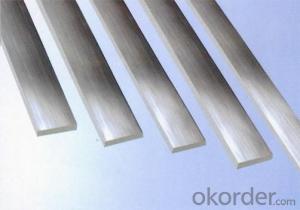

Iron Flat Steel Bars Slitted by Cutting Machine

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000T m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Iron Flat Steel Bars Slitted by Cutting Machine at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Iron Flat Steel Bars Slitted by Cutting Machine are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Iron Flat Steel Bars Slitted by Cutting Machine are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: slited

Slitting precision (width) : 0.5 mm or less

Raw material: Q235B, Q345B, Q235-1 b

crosscutting precision (length) : 2 mm or less

Processing: the thickness of 2.0-16 mm;

Shear length: 2000 mm above

Wide degree: 15-1250 - mm;

Leveling precision: 1-2 MM square

Packaging: Export packing, nude packing, bundled

FAQ:

Q1: How many tons of steel products could be loaded in containers?

A1: Usually the steel products are delivered by bulk vessel because of the large quantity and the freight. However, there are no bulk vessel enter some seaports so that we have to deliver the cargo by containers. The 6m steel product can be loaded in 20FT container, but the quantity is changed according to the size, usually from 18tons to 25tons.

Q2: what is the difference between actual weight and theoretical weight?

A2: All the section steel has two weights: actual weight and theoretical weight. Actual weight is the weighing out when the product delivered from the mill. Theoretical weight is calculated by pieces. The invoice can be based on each of them as your request.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days..

Images:

- Q: Are steel flat bars suitable for making gears or sprockets?

- When it comes to making gears or sprockets, steel flat bars are a truly suitable option, particularly if they are crafted from top-notch steel. Steel possesses exceptional strength, durability, and resistance to wear and tear, rendering it an outstanding material for gears and sprockets that must endure heavy loads and repetitive movements. Furthermore, steel can be easily manipulated and molded into the desired gear or sprocket shapes, making it a versatile choice for such applications. Nevertheless, it is crucial to bear in mind that the specific requirements of the gears or sprockets, including size, tooth profile, and surface finish, must be taken into account when choosing the appropriate steel flat bar for the task at hand.

- Q: Are steel flat bars suitable for outdoor signage or displays?

- Yes, steel flat bars are indeed suitable for outdoor signage or displays. Steel is a highly durable and weather-resistant material, making it ideal for withstanding the elements and ensuring long-lasting performance in outdoor environments. The flat bar shape provides a sturdy and stable foundation for hanging or mounting various types of signage or displays. Additionally, steel can be easily customized and manipulated to fit specific design requirements, allowing for endless creative possibilities in outdoor advertising and branding. Overall, steel flat bars are a reliable and versatile choice for outdoor signage or displays, ensuring durability, strength, and visual impact.

- Q: Can steel flat bars be used in the aerospace industry?

- Indeed, in the aerospace industry, steel flat bars find ample application. Steel, owing to its exceptional strength, durability, and versatility, is extensively employed across diverse sectors, including aerospace. In the construction of aircraft frames, wings, landing gears, and other structural elements, steel flat bars prove invaluable. They establish a robust and dependable support system, assuring the aircraft's structural integrity and safety. Moreover, these bars can be skillfully machined and fabricated to cater to the precise demands and performance benchmarks of the aerospace industry.

- Q: How do you join two steel flat bars together?

- Depending on the desired strength and aesthetic appeal of the final joint, there are various methods available for joining two steel flat bars. One commonly used technique is welding, where the two flat bars are heated until they reach a molten state and then fused together using either an electric arc or a gas flame. This process results in a robust and durable joint, but it requires skill and specialized equipment to be executed effectively. Additionally, welding can leave visible weld marks that may require smoothing or finishing. Alternatively, mechanical fasteners such as bolts, screws, or rivets can be employed. This method involves drilling holes through both flat bars and subsequently securing them together using the chosen fastener. Mechanical fasteners offer a sturdy joint and can be easily dismantled if necessary. However, they may not provide the same level of strength as welding and may also be visible, depending on the selected fastener. Another option is adhesive bonding, which involves using a high-strength adhesive specially designed for bonding metal. The adhesive is applied to the contact surfaces of the flat bars, and then they are firmly pressed together until the adhesive cures. Adhesive bonding can yield a strong and visually appealing joint, although its strength may not match that of welding or mechanical fasteners in certain applications. Ultimately, the most suitable method for joining two steel flat bars together depends on the specific requirements of the project. It is advisable to consult with a professional or an experienced metalworker to determine the optimal joining technique for your particular needs.

- Q: Are steel flat bars suitable for making frames or supports?

- Yes, steel flat bars are suitable for making frames or supports. They are known for their strength, durability, and stability, making them an ideal choice for constructing frames and supports that require structural integrity and load-bearing capabilities. Additionally, steel flat bars can be easily welded or bolted together, providing flexibility in design and construction.

- Q: What are the different types of steel alloys used for flat bars?

- There are several different types of steel alloys that are commonly used for flat bars, each with its own unique properties and advantages. Some of the most common types include: 1. Carbon Steel: This is the most basic and widely used type of steel alloy for flat bars. It consists mainly of iron and carbon, with small amounts of other elements. Carbon steel is known for its strength and durability, making it suitable for a wide range of applications. 2. Stainless Steel: This type of steel alloy contains a high percentage of chromium, which gives it excellent corrosion resistance. Stainless steel flat bars are often used in environments where they may be exposed to moisture or harsh chemicals. 3. Alloy Steel: This category includes a wide range of steel alloys that have been specially formulated to enhance specific properties. For example, some alloy steels have increased strength, while others have improved heat resistance or wear resistance. Alloy steel flat bars are commonly used in industries such as construction, automotive, and manufacturing. 4. Tool Steel: This type of steel alloy is specifically designed to have high hardness, wear resistance, and toughness. Tool steel flat bars are commonly used in the production of tools, dies, and molds. 5. Spring Steel: As the name suggests, this type of steel alloy is known for its ability to retain its shape and strength even when subjected to repeated bending or twisting. Spring steel flat bars are widely used in the manufacture of springs, clips, and other components that require elasticity. These are just a few examples of the different types of steel alloys used for flat bars. The choice of alloy depends on the specific application and desired properties, such as strength, corrosion resistance, or wear resistance.

- Q: What are the different types of edge finishes available for steel flat bars?

- There are several different types of edge finishes available for steel flat bars, including square, rounded, beveled, chamfered, and decorative profiles. These finishes can enhance the appearance, safety, and functionality of the steel flat bars depending on the specific requirements and applications.

- Q: Can steel flat bars be used for manufacturing construction equipment?

- Yes, steel flat bars can be used for manufacturing construction equipment. Steel flat bars are commonly used in the construction industry for various applications such as structural supports, framework, and reinforcement due to their strength, durability, and versatility. They provide stability and reliability, making them suitable for manufacturing heavy-duty construction equipment.

- Q: Can steel flat bars be used for staircases?

- Yes, steel flat bars can be used for staircases. They are often used as stringers or supports for the steps and provide stability and durability to the staircase structure.

- Q: Are steel flat bars available in different lengths for packaging purposes?

- Yes, steel flat bars are available in different lengths for packaging purposes.

Send your message to us

Iron Flat Steel Bars Slitted by Cutting Machine

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000T m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords