High Quality Stainless Steel Round Steel bar

- Loading Port:

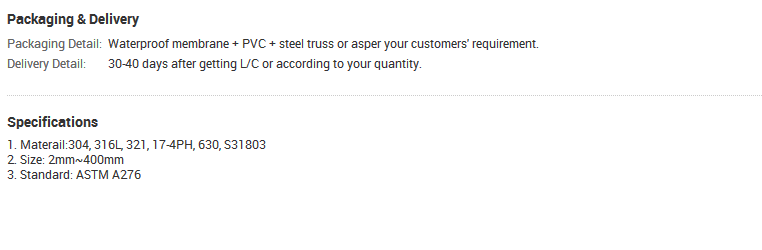

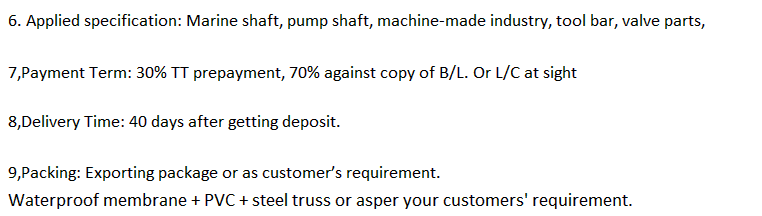

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: Can stainless steel pipes be used for food processing equipment?

- Yes, stainless steel pipes can be used for food processing equipment. Stainless steel is a preferred material for food processing due to its corrosion resistance, easy cleaning, and durability. It is also non-reactive, ensuring that it does not contaminate the food being processed.

- Q: Can stainless steel pipes be used for gas or oil transportation?

- Yes, stainless steel pipes can be used for gas or oil transportation. Stainless steel pipes are known for their excellent corrosion resistance properties, making them a suitable choice for transporting corrosive fluids such as gas or oil. They are resistant to rust, oxidation, and other forms of corrosion, which ensures the integrity and longevity of the pipes. Additionally, stainless steel pipes have high strength and durability, making them capable of withstanding high-pressure applications commonly associated with gas or oil transportation. The smooth inner surface of stainless steel pipes also offers low frictional resistance, enabling efficient flow of fluids. However, it is important to consider factors such as the grade of stainless steel, compatibility with the specific gas or oil being transported, and compliance with relevant industry standards and regulations while selecting stainless steel pipes for gas or oil transportation.

- Q: Can stainless steel pipes be used for brewery applications?

- Yes, stainless steel pipes can be used for brewery applications. Stainless steel is the preferred material for many breweries due to its excellent corrosion resistance, durability, and hygienic properties. Stainless steel pipes do not react with the ingredients in beer, ensuring the purity and taste of the final product. They are also easy to clean and maintain, reducing the risk of contamination. Additionally, stainless steel pipes can withstand high temperatures and pressures, making them suitable for various brewery processes such as brewing, fermentation, and storage. Overall, stainless steel pipes are a reliable and long-lasting choice for brewery applications.

- Q: What is the maximum pressure rating for stainless steel pipe fittings?

- The maximum pressure rating for stainless steel pipe fittings varies depending on factors such as the size, type, and wall thickness of the fittings. It is important to refer to the manufacturer's specifications for accurate and specific pressure ratings for each stainless steel pipe fitting.

- Q: Can stainless steel pipes be used for oil and gas pipelines?

- Certainly, oil and gas pipelines can utilize stainless steel pipes. Stainless steel possesses remarkable resistance to corrosion, rendering it an apt material for the conveyance of oil and gas, which may encompass corrosive components. Stainless steel pipes exhibit the capacity to endure elevated temperatures and pressures, thereby rendering them optimal for oil and gas applications. Furthermore, stainless steel exhibits durability and longevity, thereby diminishing the likelihood of pipeline system leaks or malfunctions. The utilization of stainless steel pipes for oil and gas pipelines guarantees the integrity and dependability of the infrastructure, safeguarding both environmental preservation and public safety.

- Q: Can stainless steel pipes be used for food processing?

- Indeed, stainless steel pipes are suitable for food processing purposes. The food industry favors stainless steel due to its remarkable resistance to corrosion, remarkable strength, and hygienic features. Its non-reactive nature ensures that it does not interact with food or introduce any flavor or scent. Stainless steel pipes are effortless to clean, sanitize, and upkeep, rendering them appropriate for employment in food processing scenarios where cleanliness and hygiene hold paramount importance. Furthermore, stainless steel pipes exhibit the capability to endure elevated temperatures and pressures, thus making them an ideal choice for a diverse range of food processing activities, including the transportation, storage, and distribution of food products.

- Q: What is the difference between seamless and double submerged arc welded stainless steel pipes?

- The main difference between seamless and double submerged arc welded stainless steel pipes lies in their production process. Seamless pipes are manufactured without any welding or seams, resulting in a smooth and continuous pipe with uniform strength throughout. On the other hand, double submerged arc welded pipes are created by welding two separate pieces of steel together using the submerged arc welding method. This creates a welded joint along the length of the pipe. While both types of pipes have their own advantages and applications, seamless pipes are generally preferred for their superior strength, durability, and resistance to corrosion.

- Q: What is the maximum pressure rating for stainless steel pipes?

- The maximum pressure rating of stainless steel pipes can vary due to several factors, including the stainless steel grade, pipe diameter and wall thickness, and specific application or industry requirements. Nonetheless, stainless steel pipes are renowned for their exceptional strength and resistance to corrosion, making them ideal for high-pressure applications. Generally, stainless steel pipes can withstand maximum pressure ratings ranging from a few hundred psi to several thousand psi. To determine the precise maximum pressure rating for a specific stainless steel pipe in a given application, it is imperative to refer to the relevant industry standards, codes, and specifications or seek guidance from a qualified engineer or manufacturer.

- Q: What is the difference between seamless and longitudinal welded stainless steel pipes?

- The main difference between seamless and longitudinal welded stainless steel pipes lies in their manufacturing processes. Seamless pipes are made by piercing a solid cylindrical billet to form a hollow tube, while longitudinal welded pipes are produced by joining multiple pieces of steel plates or coils together along the length of the pipe. This welding process can result in a visible seam on the surface of the pipe. Additionally, seamless pipes generally have higher strength and are more suitable for high-pressure applications, whereas welded pipes are commonly used for lower-pressure applications and where cost-effectiveness is a priority.

- Q: Are stainless steel pipes suitable for high-pressure steam applications?

- Yes, stainless steel pipes are suitable for high-pressure steam applications. Stainless steel is known for its excellent corrosion resistance, high temperature resistance, and strength, making it an ideal material for handling high-pressure steam. The pipes' ability to resist corrosion ensures that they can withstand the harsh conditions and prevent any leakage or failure. Additionally, stainless steel pipes can handle high temperatures without deforming or weakening, ensuring the safe and efficient transfer of steam. Overall, stainless steel pipes are a reliable choice for high-pressure steam applications due to their durability, corrosion resistance, and ability to withstand high temperatures.

Send your message to us

High Quality Stainless Steel Round Steel bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords