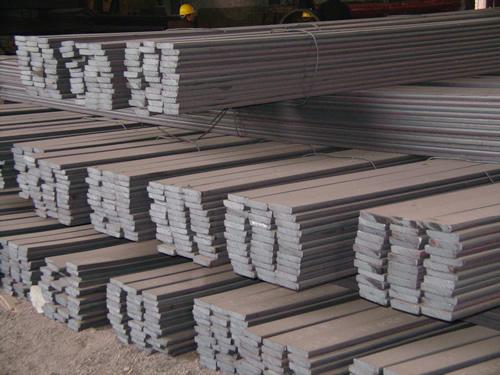

Cold Slitted Steel Flat Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality Cold Slitted Flat Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Cold Slitted Flat Bar are ideal for make ladders, steel grating bars,Machinery manufacturing,Iron tower steel structure;Shipbuilding; Steel grating;Staircase;Bridge;Viaduct;Railway spare parts;Boilers making etc.

Product Advantages:

OKorder's Cold Slitted Flat Bar are durable and strong

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Cold Slitted

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: Can steel flat bars be used for making brackets or supports for transportation infrastructure?

- Yes, steel flat bars can be commonly used for making brackets or supports for transportation infrastructure due to their strength, durability, and ability to withstand heavy loads.

- Q: Can steel flat bars be heat treated?

- Steel flat bars can indeed undergo heat treatment. Heat treatment is a useful technique for modifying the physical and mechanical properties of steel by subjecting it to specific heating and cooling cycles. It is a widely employed process for enhancing the hardness, strength, and toughness of steel flat bars. Depending on the desired results, heat treatment can be carried out through various methods, including annealing, normalizing, quenching, and tempering. Each of these methods involves heating the steel to a specific temperature and then carefully controlling the cooling rate. Heat treatment finds extensive application in industries such as manufacturing, construction, and automotive to improve the performance and durability of steel flat bars.

- Q: Can steel flat bars be used for making brackets or supports for telecommunications towers?

- Certainly! Steel flat bars have the capability to be utilized in the creation of brackets or supports for telecommunications towers. Steel, being a robust and long-lasting material, possesses the ability to provide the essential structural support these towers require. The flat configuration of the bars enables trouble-free fabrication and attachment to the tower structure. Moreover, steel exhibits resistance to environmental elements like corrosion, rendering it suitable for outdoor applications. Nevertheless, it is imperative to guarantee that the steel flat bars employed adhere to the necessary specifications and standards for constructing telecommunications towers, thus assuring the safety and stability of the structure.

- Q: What are the tolerances for steel flat bars?

- The tolerances of steel flat bars may differ based on the specific requirements and standards set by the manufacturer or customer. However, typically, the tolerances for steel flat bars are measured in terms of thickness, width, and length. Concerning the thickness tolerance, it is customary to have a specific range in which the flat bar's thickness should fall. This range can vary depending on the grade and type of steel used, but it is usually specified as a plus or minus value. Similarly, the width tolerance denotes the acceptable variation in the width of the steel flat bar. This tolerance is usually specified as a plus or minus value, allowing for a certain range of deviation from the desired width. Lastly, the length tolerance determines the acceptable variation in the length of the steel flat bar. This tolerance is often specified as a maximum or minimum deviation from the desired length. It is crucial to note that the precise tolerances for steel flat bars may vary depending on the application and industry standards. Consequently, it is important to refer to the relevant specifications or standards provided by the manufacturer or customer to ascertain the exact tolerances required for a specific steel flat bar.

- Q: Are steel flat bars available in different lengths and widths?

- Indeed, an assortment of lengths and widths can be found for steel flat bars. The specific product and manufacturer play a significant role in determining the available options for length and width. Typically, steel flat bars can be obtained in lengths spanning from 6 feet to 20 feet, while widths can extend from 1/2 inch to 12 inches or even more. This broad range of variations in length and width offers enhanced flexibility in selecting the appropriate size of steel flat bars to cater to the specific requirements of any given project or application.

- Q: Can steel flat bars be used for making brackets or supports for lighting fixtures?

- Yes, steel flat bars can be used for making brackets or supports for lighting fixtures. Steel flat bars are strong and durable, making them suitable for providing structural support and stability to lighting fixtures. Additionally, steel's high load-bearing capacity ensures that the brackets can effectively hold the weight of the lighting fixtures.

- Q: Can steel flat bars be used for creating frames or supports in artwork?

- Certainly, frames or supports in artwork can indeed be crafted using steel flat bars. Steel, being a robust and long-lasting material, offers stability and structural integrity to art pieces. Its strength enables it to bear the weight of larger artworks or serve as a solid foundation for sculptures. When it comes to customization, steel flat bars can be effortlessly trimmed, welded, and molded to fit any desired dimensions or design for the frame or support. Moreover, steel's resistance to corrosion guarantees the longevity of the artwork. This adaptability and dependability render steel flat bars an exceptional option for crafting frames or supports in diverse forms of artwork.

- Q: Are steel flat bars suitable for making machinery frames or chassis?

- Certainly, machinery frames or chassis can be constructed using steel flat bars. Steel, renowned for its robustness and endurance, proves to be an optimal option for creating resilient and dependable machinery frames or chassis. The flat bars' shape facilitates effortless fabrication and welding, enabling the construction of frames or chassis with impeccable measurements and structural soundness. Moreover, steel possesses exceptional load-bearing capabilities, enabling it to withstand substantial burdens and furnish stability to the machinery. Furthermore, steel's abundance and cost-effectiveness compared to alternative materials render it a favored choice for fabricating machinery frames or chassis across diverse industries.

- Q: Are steel flat bars available in different colors or coatings?

- Different colors or coatings are not typically available for steel flat bars. Steel is usually left in its natural state, which is a dark gray or silver color. However, it is possible to add coatings or finishes to steel flat bars for specific purposes like protecting against corrosion or improving appearance. These coatings may include galvanized coatings that add a layer of zinc to prevent rusting, or powder coatings that can provide color to the steel. However, these coatings are usually applied after the steel has been shaped into flat bars and are not easily found in a wide variety of colors or finishes.

- Q: What are the different types of steel surface treatments available for flat bars?

- There are several types of steel surface treatments available for flat bars, each serving different purposes and providing various benefits. Some of the common types include: 1. Hot-dip galvanizing: This treatment involves immersing the flat bars in a bath of molten zinc, creating a protective coating that prevents corrosion. It provides excellent corrosion resistance and is often used in outdoor or marine applications. 2. Powder coating: Powder coating involves applying a dry powder to the surface of the flat bars and then heating it to form a durable and decorative coating. This treatment provides excellent resistance to chipping, scratching, and fading, making it suitable for applications where aesthetics and durability are important. 3. Electroplating: In electroplating, a thin layer of metal is deposited onto the surface of the flat bars using an electric current. Common metals used for electroplating include chrome, nickel, and zinc. This treatment enhances the appearance of the flat bars and provides corrosion resistance. 4. Passivation: Passivation is a chemical treatment that removes impurities and contaminants from the surface of the steel, improving its corrosion resistance. This treatment is commonly used for stainless steel flat bars to enhance their resistance to corrosion and staining. 5. Shot blasting: Shot blasting involves propelling small steel balls or other abrasive materials at high speeds onto the surface of the flat bars. This treatment removes rust, scale, and other impurities, creating a clean and textured surface that improves adhesion of coatings or paints. 6. Acid pickling: Acid pickling is a process where the flat bars are immersed in an acid solution to remove scale, rust, and other impurities from the surface. This treatment improves the appearance and cleanliness of the flat bars, making them more suitable for subsequent processes like painting or plating. It is important to choose the appropriate surface treatment based on the specific requirements of the application, such as the desired level of corrosion resistance, aesthetics, or durability. Consulting with a professional or a steel supplier can help determine the most suitable treatment for flat bars in a particular use case.

Send your message to us

Cold Slitted Steel Flat Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords