High Quality Aluminum Wall Sheets for Electric Shells

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

Aluminum sheet checkered /Aluminum sheet embossing sheet

| Material | 1000 series: 1050. 1070. 1100 2025. 2117. 2218. 2618. 6000 series: 6005. 6011. 6053. 6351. 6061. 6101. 6151. 6201. 6261. 6262. 6063. 6463. 6066.6070 7000series: 7001. 7005. 7072. 7075. 7076. 7175. 7178. 7079 8000 series:8011,8021,8079 etc |

| Standard | GB/T17748-2008 |

| Certification | ISO9001,ISO14001, ISO9001:2000 |

| Temper | T4,T5,T6,H111,H112 |

| Surface treatment | Polished,Mill Finished,anodized or power sprayed |

| Features | High weather resistance anti scratch anticorrosion and good weather resistance subtle edges and elegant appearance and easy processing and installation high brightness and hardness |

| Resolution | 2%-98% |

| Advantages | 1)Excellent machining properties 2)Suited to marine and low temp applications |

| Note | If you have any other questin,welcome for your consultation |

1)Chemical compositions&mechanical property&Size

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

5005 | 0.30 | 0.70 | 0.20 | 0.20 | 0.50-1.10 | 0.10 | 0.25 | - | spare |

5052 | 0.25 | 0.40 | 0.10 | 0.10 | 2.2-2.8 | 0.15-0.35 | 0.10 | spare | |

5083 | 0.40 | 0.40 | 0.10 | 0.40-1.0 | 4.0-4.9 | 0.05-0.25 | 0.25 | 0.15 | spare |

6060 | 0.30 -0.6 | 0.10 -0.30 | ≤0.10 | ≤0.10 | 0.35~0.6 | ≤0.05 | ≤0.15 | ≤0.10 | spare |

Packaging & Shipping

Package: Standard seaworthy packing or as per request

Transports:Containler sizes:

20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High)

40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High)

Our Services

1 Customer and reputation first

2 Timely feedback

3 Low MOQ

4Timely delivery

5 Competitive price

6Different size can be supplyed as your request

7 Professional service of technical and shipping support

8More than 30 years experience in the cold and hot rolled sheet/coil/stri experience

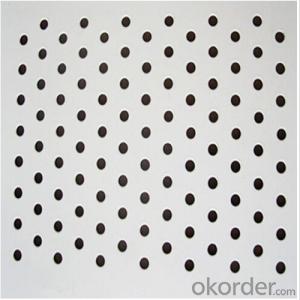

Photos

- Q: What is the lifespan of aluminum sheets?

- The lifespan of aluminum sheets can vary depending on various factors such as the grade and thickness of the aluminum, the environmental conditions it is exposed to, and how well it is maintained. Generally, aluminum sheets are known for their durability and corrosion resistance, which can contribute to a long lifespan. Aluminum is naturally resistant to rust and corrosion, making it suitable for a wide range of applications. With proper care and maintenance, aluminum sheets can last for many years. They are commonly used in construction, automotive, and aerospace industries due to their lightweight and strong properties. In outdoor environments, aluminum sheets can withstand harsh weather conditions, including extreme temperatures, humidity, and exposure to UV radiation. However, prolonged exposure to certain chemicals or corrosive substances can cause damage over time. To extend the lifespan of aluminum sheets, it is important to regularly clean and protect them. This can involve removing any dirt or debris that may accumulate on the surface and applying protective coatings or treatments as needed. Overall, while it is difficult to provide an exact lifespan for aluminum sheets, they are generally considered to be a long-lasting material that can withstand the test of time when properly cared for.

- Q: What is an aluminium plate? What is the difference between carbon steel sheet, galvanized sheet and stainless steel plate?What is the order of the price? Thank you

- It is aluminized sheet, which is mainly resistant to high temperature than galvanized sheet

- Q: Do 101 aluminum sheets have any specific fire resistance properties?

- Indeed, specific fire resistance properties are possessed by a total of 101 aluminum sheets. With a melting point of 660 degrees Celsius (1220 degrees Fahrenheit), aluminum can endure high temperatures before the onset of melting. Furthermore, due to its low combustion point, aluminum does not easily ignite. In the event of a fire, the aluminum sheets serve as a barrier that hinders the spread of flames. Furthermore, the burning of aluminum results in the formation of a protective oxide layer on its surface, which effectively impedes the advancement of the fire. Nevertheless, it is important to acknowledge that although aluminum exhibits fire-resistant characteristics, it is not entirely impervious to fire and can still suffer damage or deformation when subjected to intense heat.

- Q: What are the different surface treatments available for aluminum sheet?

- Aluminum sheet offers a variety of surface treatments, each with its own benefits and purposes. Anodizing, painting, powder coating, and polishing are some of the most commonly used methods. Anodizing, for instance, involves an electrochemical process that develops a protective oxide layer on the aluminum sheet's surface. This treatment not only enhances its corrosion resistance but also adds an attractive finish. Anodized aluminum can be dyed in different colors, making it a popular choice for architectural and decorative uses. Painting, on the other hand, is a widely employed surface treatment for aluminum sheet. It entails applying a liquid paint coating to the surface, providing protection and aesthetic appeal. Painted aluminum sheets are frequently utilized in building facades, automotive parts, and other applications where a vibrant and long-lasting finish is desired. Powder coating, a dry finishing process, is also popular. It involves electrostatically applying a powder coating to the aluminum sheet and then curing it under heat. This treatment offers excellent corrosion resistance, durability, and a wide range of color options. Powder-coated aluminum sheets are often found in outdoor furniture, commercial signage, and architectural applications. For a smooth and shiny finish, polishing is a mechanical surface treatment that involves grinding or buffing the aluminum sheet. This treatment is commonly used for decorative purposes in jewelry, automotive trim, and upscale appliances. Choosing the right surface treatment for aluminum sheet depends on the intended application and desired appearance. Each treatment has unique properties and characteristics, so consulting with experts or professionals in the field is highly recommended to determine the most suitable option for specific requirements.

- Q: What is the thermal conductivity of aluminum sheets?

- Aluminum sheets exhibit high thermal conductivity, reaching around 237 W/m·K. This quality endows aluminum with exceptional heat conduction capabilities, enabling efficient heat transfer between different regions. Consequently, aluminum sheets find widespread application in various domains, including heat sinks, radiators, and cooking pans.

- Q: A copper-aluminum alloy has an aluminum concentration of (5.19x10^2) kg/m3.If the densities of aluminum and copper are 2.71 and 8.94 g/cm3, respectively, what is the concentration of aluminum in wt%?Could someone please help wit this question, im lost

- Densities: Aluminum: 2,710 kg/m^3 Copper: 8,940 kg/m^3 Basis: 1 m^3 of copper-aluminum alloy mass of aluminum in 1 m^3 alloy = 519 kg vol. of aluminum in the 1 m^3 alloy = 519 kg/(2710 kg/m^3) = 0.1915 m^3 vol. of copper in 1 m^3 alloy = 1 m^3 - 0.1915 m^3 = 0.8085 m^3 mass of copper in 1 m^3 alloy = (0.8085 m^3)*(8,940 kg/m^3) = 7,227.87 kg mass of the m^3 alloy = 7,227.87 kg + 519 kg = 7,746.87 kg %weight of aluminum = (519 kg/7,746.87 kg)*100% = 6.70% The alloy has 6.70% by weight of aluminum in it.

- Q: Are aluminum sheets suitable for interior design applications?

- Yes, aluminum sheets are suitable for interior design applications. Aluminum is a versatile and durable material that can be used in various ways to enhance the aesthetics of interior spaces. It can be easily shaped, cut, and manipulated to create unique and modern designs. Aluminum sheets are available in different finishes, such as brushed, polished, or textured, which allows for a wide range of design possibilities. One of the main advantages of using aluminum sheets in interior design is their lightweight nature. This makes them easy to handle and install, reducing labor and transportation costs. Additionally, aluminum is resistant to corrosion, making it suitable for areas with high humidity or moisture, such as bathrooms or kitchens. Aluminum sheets can be used for various applications in interior design, including wall cladding, ceiling panels, room dividers, furniture, and decorative elements. They can be painted or coated in different colors to match any interior design scheme. Aluminum sheets can also be perforated or engraved to create patterns or intricate designs, adding a unique visual appeal to the space. Furthermore, aluminum is a sustainable material as it is highly recyclable. Its recycling process requires only a fraction of the energy needed to produce new aluminum, making it an eco-friendly choice for interior design applications. In conclusion, aluminum sheets are highly suitable for interior design applications due to their versatility, durability, lightweight nature, resistance to corrosion, and ability to be shaped and manipulated. They offer a wide range of design possibilities and can be used for various applications, making them a popular choice among designers and architects.

- Q: What are the distinctions among various grades of aluminum sheets?

- <p>Yes, there are differences between different grades of aluminum sheets. These differences are primarily based on the alloy composition, which affects properties such as strength, formability, and corrosion resistance. For instance, 1000 series aluminum is pure and soft, making it ideal for general purposes. 2000 series is harder and stronger, often used in aerospace applications. 3000 series is known for its high resistance to corrosion and is used in marine applications. 5000 series offers good strength-to-weight ratio and is used in structural applications. 6000 series is known for its strength and is used in construction and industrial applications. Each grade has specific uses based on its unique characteristics.</p>

- Q: bending, bending phenomenon will occur, I would like to annealing treatment. Does the master know the annealing temperature and time?

- And the same direction in the rolling, more than 1.5 of the thickness of cracking is more serious; it is proposed to increase the bending angle of R, annealing may not be solved.Or on the bending line and calendering line to cross 45 degrees (comparison fee)

- Q: Is it possible to purchase recycled aluminum sheets from a local supplier or manufacturer?

- <p>Yes, you can buy recycled aluminum sheets from local suppliers or manufacturers. Many businesses specialize in recycling and repurposing materials, including aluminum. To find a local supplier, you can search online directories or use business listing services. Additionally, contacting local recycling centers or metalworking businesses may provide leads on available recycled aluminum sheets. It's important to consider the quality, certifications, and environmental impact of the recycled materials when making your purchase.</p>

Send your message to us

High Quality Aluminum Wall Sheets for Electric Shells

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords