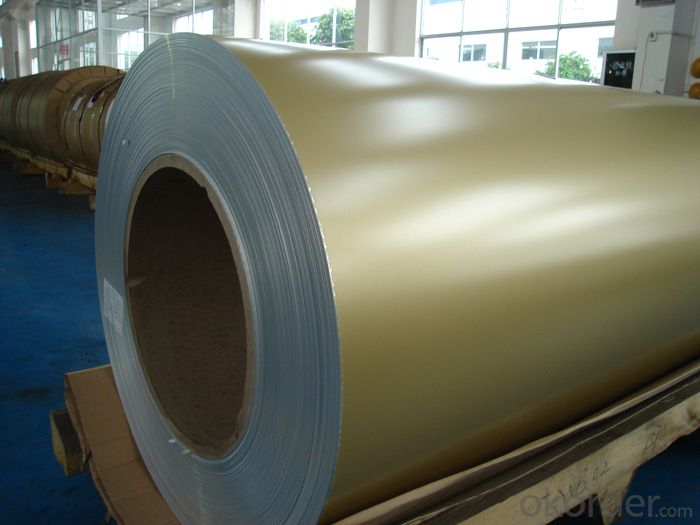

Aluminum Curtain Wall Coils and Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Alloy: 5052(AlMg2.5)

Temper: O,H12,H22,H32,H14,H24,H34,H16,H26,H36,H18,H38,F

CHEMICAL COMPOSITION LIMITS (%)

Silicon | Iron | Copper | Manganese | Magnesium | Chromium | Nickel | Zinc | Titanium | Others | Total | Aluminum |

0.25 | 0.4 | 0.10 | 0.10 | 2.2-2.8 | 0.15-0.35 | 0.10 | 0.05 | 0.15 |

Remainder |

Main application: Magnesium gives this alloy its enhanced corrosion resistance, workability, strength and weldability. Typical uses include aircraft fuel tanks, container body, truck/trailer body, electronic mounting plates and panels, fan blades, refrigeration liners, storm shutters and utensils.

Mechanical Property Limits

Alloy | Temper | Thickness(mm) | Tensile Strength(MPa) | Elg%(50mm) |

5052 | O | >0.5-0.8 >0.8-1.3 >1.3-6.5 >6.5-10.0 | 170-215

| ≥15 ≥17 ≥19 ≥18 |

H12/H22/H32 | >0.5-1.3 >1.3-4.5 | 215-265 | ≥5 ≥7 | |

H14/H24/H34 | >0.5-0.8 >0.8-1.3 >1.3-4.5 | 235-285 | ≥3 ≥4 ≥6 | |

H16/H26/H36 | >0.5-0.8 >0.8-4.5 | 255-305 | ≥3 ≥4 | |

H18/H38 | >0.5-0.8 >0.8-4.5 | ≥270 | ≥3 ≥4 | |

H112 | >4.5-6.5 | ≥195 | ≥9 ≥7 | |

>6.5-12.5 | ≥195 | |||

>12.5-40.0 | ≥175 | |||

>40.0-80.0 | ≥175 |

Our Services

Payment: by 30%T/T in advance and balance before shipment or 100% L/C at sight

Delivery: within 30 days after we get your deposit or L/C.

Packing: sea worthy wooden pallet

Loading port: Qingdao/Shanghai/Tianjin, China

FAQ

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, D/A, D/P, T/T, West Union,etc.

If you are interested in our products, please do not hesitate to contact with us via following information

- Q: Is it possible to use aluminum as a substance that accelerates chemical reactions?

- <p>Aluminum is not typically used as a catalyst in chemical reactions. Catalysts are substances that increase the rate of a chemical reaction without being consumed in the process. Aluminum, being a metal with a +3 oxidation state, does not readily participate in reactions where it could act as a catalyst. Instead, it is more commonly used in its elemental form for structural purposes or as a reducing agent in certain chemical processes. However, aluminum compounds, such as alumina (Al2O3), can be used as catalysts or catalyst supports in specific industrial applications.</p>

- Q: This question asks for a list of typical aluminum alloys that are widely used in various industries.

- <p>Common types of aluminum alloys include 1000 series, which are nearly pure aluminum; 2000 series, known for their strength due to copper content; 3000 series, which are alloyed with manganese for good formability; 5000 series, featuring magnesium for improved strength and corrosion resistance; 6000 series, which are popular for their strength and heat treatability; and 7000 series, recognized for their highest strength among aluminum alloys, often used in aerospace and automotive applications. Each series offers unique properties that make them suitable for specific applications.</p>

- Q: Is it possible to utilize aluminum in the construction of automobiles?

- <p>Yes, aluminum is widely used in automobiles due to its lightweight, high strength, and excellent corrosion resistance. It is commonly found in engine components, body panels, and wheels. The use of aluminum can lead to reduced vehicle weight, which improves fuel efficiency and reduces emissions. Additionally, aluminum's recyclability makes it an environmentally friendly choice for automotive manufacturing.</p>

- Q: Is aluminum a suitable material for manufacturing bicycles and other lightweight vehicles?

- <p>Yes, aluminum is a popular material for making bicycles and other lightweight vehicles due to its high strength-to-weight ratio. It is lightweight, durable, and resistant to corrosion, which makes it an excellent choice for components that need to be strong yet not add excessive weight. Aluminum frames are commonly used in bicycles because they offer a good balance between weight, stiffness, and cost. Additionally, aluminum is widely used in the manufacturing of other lightweight vehicles such as electric scooters, small cars, and even aircraft due to its favorable properties.</p>

- Q: Explain the impact of high-temperature cooking on aluminum cookware.

- <p>High-temperature cooking can have detrimental effects on aluminum cookware. When exposed to high heat, aluminum can react with acidic or alkaline foods, potentially causing the release of aluminum particles into the food. This can lead to a change in the taste and color of the food, and over time, it may also lead to the degradation of the cookware's surface, causing it to become discolored or pitted. Additionally, there are health concerns related to the ingestion of aluminum, although these are still a subject of debate among scientists. It's generally recommended to use aluminum cookware on low to medium heat to preserve both the quality of the food and the longevity of the cookware.</p>

- Q: This question asks for various applications or purposes that can be served by using aluminum scrap material.

- <p>Aluminum scrap can be repurposed in numerous ways due to its recyclability and durability. Some alternative uses include manufacturing new aluminum products, such as cans, foil, and automotive parts. It can also be used in construction for materials like window frames and roofing. Additionally, aluminum scrap is utilized in the production of everyday items like bicycles, furniture, and even in some types of cookware. Furthermore, it can be employed in the aerospace industry for aircraft parts and in the electronics industry for components. Recycling aluminum scrap not only conserves resources but also reduces energy consumption and environmental impact.</p>

- Q: This question asks for a comparison of the benefits and drawbacks of using aluminum foil in the culinary process.

- <p>Aluminum foil offers several advantages in cooking, such as easy clean-up, even heat distribution, and the ability to create a seal for steaming or baking. It's also versatile, being suitable for both roasting and wrapping food for baking. However, there are disadvantages, including potential health concerns due to the leaching of aluminum into food, especially at high temperatures. Additionally, foil can tear easily, and it's not suitable for non-stick surfaces or use under broilers. Environmentally, it's not biodegradable and contributes to waste, which is a significant disadvantage.</p>

- Q: Is it possible to develop allergies from exposure to aluminum found in food packaging materials?

- <p>While aluminum is commonly used in food packaging materials, the risk of allergic reactions to aluminum is generally low for most people. Aluminum is not a known allergen, and exposure through packaging is typically minimal. However, individuals with a rare condition called contact dermatitis may experience skin irritation from aluminum. For the general population, the risk of allergic reactions due to aluminum in food packaging is negligible. It's always important to monitor any unusual reactions and consult a healthcare professional if concerned.</p>

- Q: This question seeks to understand the safety standards that aluminum products must adhere to, ensuring they are safe for use and do not pose health or environmental risks.

- <p>Safety standards for aluminum products vary by region and application but generally focus on ensuring the products are safe for their intended use and do not pose health or environmental risks. Standards often cover material composition, manufacturing processes, and finished product testing. For example, the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) provide standards for aluminum alloys and their applications. Additionally, the Food and Drug Administration (FDA) has specific guidelines for aluminum used in food contact materials to prevent contamination. Compliance with these standards is crucial for manufacturers to maintain product safety and consumer trust.</p>

- Q: What are the various applications of aluminum in the construction industry?

- <p>Aluminum is widely used in construction due to its lightweight, durability, and resistance to corrosion. It is utilized in the manufacturing of window frames, doors, roofing, and facades for its strength and low maintenance requirements. Aluminum is also used in structural components such as beams and columns, and in the construction of bridges and high-rise buildings. Its malleability allows for easy shaping and forming, making it ideal for intricate designs. Additionally, aluminum's thermal conductivity and reflectivity make it suitable for energy-efficient construction.</p>

Send your message to us

Aluminum Curtain Wall Coils and Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords