High Quality Aluminum Sheets for Curtain Wall Raleigh

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Sheets for Curtain Wall with HIgh Quality

Our aluminum sheets are widely used in solar energy curtain wall. It integrates a photo-voltaic system. Photovoltaic panels are usually installed on the glass of curtain wall to generate electricity from solar energy.

Our aluminum sheets can meet the highest standards in its own mill while save the cost. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier. CNBM aluminum complying with YS/T 429-2000(Chinese Industry Standard),GB/T 3880,EN485,ASTM B209.

2.Main Features of Aluminum Sheets for Curtain Wall with HIgh Quality

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

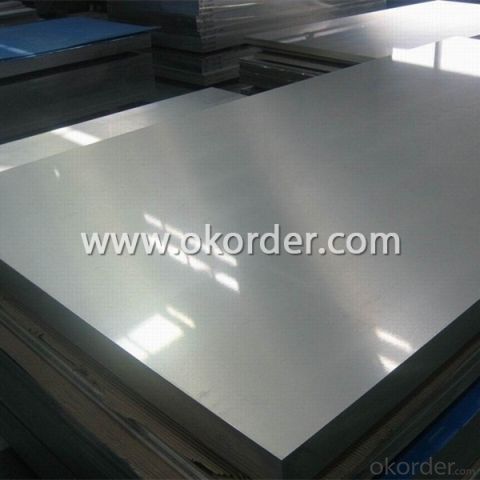

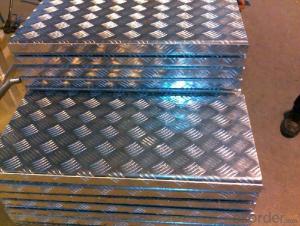

3. Aluminum Sheets for Curtain Wall with HIgh Quality Images

4.Specification of Aluminum Sheets for Curtain Wall with HIgh Quality

Alloy | AA1050,AA1060, AA1070, AA1100 |

Temper: | H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness: | 0.10-500mm |

Width: | 10mm- 2200mm |

Standard: | GB/T3880-2006, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement | |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Can aluminum sheet withstand heavy loads?

- Indeed, the durability of aluminum sheet is such that it can endure substantial loads. Renowned for its exceptional strength-to-weight ratio, aluminum proves to be an exceptional selection for endeavors necessitating both resilience and load-bearing capacities. Notably prevalent in sectors like aerospace, automotive, construction, and marine, aluminum sheets are frequently employed in scenarios involving weighty burdens. Moreover, the innate corrosion resistance of aluminum further fortifies its capacity to bear heavy loads for extensive durations. Nevertheless, it is crucial to take into account the precise grade and thickness of the aluminum sheet, as diverse alloys and thicknesses yield differing load capacities.

- Q: we have the mass of an aluminum sample =.47g, and the number of atoms in sample =107

- Alright - first, find the number of moles of aluminium in that sample, by dividing the mass (0.47g) by the molecular weight of aluminium (26.98). Then, having obtained the number of moles, multiply it by the avogadro's constant (6.023x1023) and you will obtain the number of atoms, and by dividing the mass by the number of atoms, you get the mass of an individual atom.

- Q: What is the weight of a standard aluminum sheet?

- The weight of a standard aluminum sheet can vary depending on its dimensions and thickness. However, on average, aluminum sheets typically weigh around 2.7 grams per cubic centimeter. To determine the weight of a specific aluminum sheet, you would need to know the dimensions (length, width, and thickness) and multiply them to obtain the sheet's volume. Then, you can multiply the volume by the density of aluminum (2.7 g/cm³) to calculate the weight in grams.

- Q: Can aluminum sheets be soldered?

- Soldering aluminum sheets is indeed possible, but it necessitates specific techniques and materials. Due to its high thermal conductivity and low melting point, traditional soldering methods pose a challenge when working with aluminum. Nevertheless, specialized soldering techniques, like the utilization of flux and a soldering iron with a high temperature, can successfully solder aluminum. Furthermore, a particular type of solder known as aluminum solder or aluminum flux-cored solder is essential, as regular solder does not adhere well to aluminum surfaces. Thoroughly cleaning the aluminum surface before soldering is crucial to ensure a sturdy bond. In summary, although soldering aluminum sheets may be more intricate compared to other metals, it is achievable with the appropriate tools, materials, and techniques.

- Q: Can aluminum sheets be used for decorative panels?

- Yes, aluminum sheets can be used for decorative panels. Aluminum is a versatile and lightweight material that can be easily shaped, cut, and formed into various designs and patterns. It offers a sleek and modern appearance, making it a popular choice for decorative applications in both residential and commercial settings. Aluminum panels can be used for a wide range of purposes, including wall cladding, ceiling panels, room dividers, signage, and more. Additionally, aluminum is resistant to corrosion and weathering, making it suitable for both indoor and outdoor use. Furthermore, aluminum panels can be customized with different finishes, such as powder coating or anodizing, to enhance their visual appeal. Overall, aluminum sheets are an excellent choice for creating decorative panels due to their aesthetic appeal, durability, and versatility.

- Q: Are aluminum sheets suitable for marine applications?

- Yes, aluminum sheets are suitable for marine applications. Aluminum is lightweight, corrosion-resistant, and has excellent strength-to-weight ratio, making it ideal for various marine applications such as boat hulls, decks, and structural components. Additionally, aluminum's low maintenance requirements and durability in harsh marine environments further contribute to its suitability for such applications.

- Q: Can aluminum sheets be used for boat building?

- Boat building can indeed incorporate aluminum sheets. The lightweight quality, durability, and resistance to corrosion make aluminum a favored material for constructing boats. Small recreational boats, larger yachts, and even commercial vessels commonly employ aluminum sheets in their construction. These sheets offer numerous benefits, including ease of manipulation, a remarkable strength-to-weight ratio, and minimal upkeep requirements. Furthermore, aluminum boats are esteemed for their exceptional buoyancy, stability, and fuel efficiency. All in all, utilizing aluminum sheets is a suitable and dependable choice for boat building.

- Q: What is the minimum bending radius for aluminum sheets?

- The minimum bending radius for aluminum sheets depends on the thickness and grade of the aluminum. However, as a general guideline, it is recommended to have a minimum bending radius of 1.5 times the thickness of the aluminum sheet.

- Q: Is aluminum suitable for projects with heavy traffic or frequent use?

- <p>Yes, aluminum sheets can be used in projects that involve high levels of traffic or heavy use. Aluminum is a lightweight, durable, and corrosion-resistant material. It can withstand significant wear and tear, making it suitable for high-traffic areas. Additionally, aluminum is easy to maintain and can be recycled, which is beneficial for long-term projects. However, it's important to consider the specific grade of aluminum and its thickness to ensure it meets the required strength and durability for your project.</p>

- Q: I am following a recipe for braised ribs that calls for wrapping the ribs in heavy duty aluminum foil. I don't have heavy duty, so can regular aluminum foil be used as a replacement?

- Paleohacks Cookbooks + Primal Sleep : 7ce24fc1fn4o2k6fh7paq8qa2m.hop.cl... 4 Offers: Fat Burning Kitchen, 101 Anti-aging Foods, Truthaboutabs Etc : 1bb8clh1autw9k86xhr9m26x21.hop.cl... Better Breads Guilt-free Desserts: Top Converting Health Offers! : da5acmc7fr4x2nb0r3gqy4vju7.hop.cl...

Send your message to us

High Quality Aluminum Sheets for Curtain Wall Raleigh

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords