High Quality Aluminum H Extrusion Profiles for Kitchenware

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminum Circles for Kitchenware

Aluminum Circles Specification

Alloy: 1050, 1060, 1070, 3003, 5052, 3105, 6061

thickness:0.15-8mm

diameter: 20-1200mm

Aluminum Circles Application

aluminum circle Tolerance: thickness tolerance +/-3%, diameter tolerance +/-1%mm

Deep drawing cookware, spinning cookware, road sign, Building Material,Insulation, and so on.

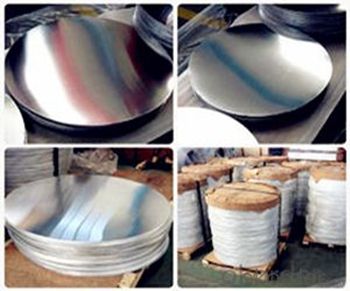

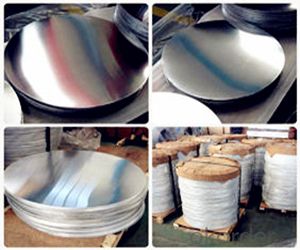

Aluminum Circles Picture

Aluminum Circles Features

1.Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use.

2.Chemical Composite and Mechanical Property could meet the requirements of GB/T, ASTM, ENAW, JIS Standard.

Aluminum Circles Packing

1.Plastic cloth with drying agent inside;

2.Pearl Wool ;

3.Wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film.

Introduction of our company

Our company is one of the largest aluminum cookware producer in China, and we have produced aluminium circles over 20years, our aluminum circles could be good quality for cookware deep drawing and spinning dawing usage.

Also we are the professional Aluminium Strip manufacturer and Aluminum Circles manufacturers,mainly supply Aluminium Coil,Aluminum Circles,Aluminium discs,Aluminum Sheet,Aluminum Strip, Household Aluminum Foil,Aluminum Foil for Pharmaceutical Packaging,Aluminum Foil Tape,Aluminum Foil for Air Conditioner,Aluminum Foil for Container etc. series of aluminum products, sincerely welcome everyone to visit.

- Q: How do I cut and shape aluminum profiles?

- To cut and shape aluminum profiles, you will need specific tools such as a miter saw, a hacksaw, or a circular saw with a carbide-tipped blade. Measure and mark the desired length on the profile, ensuring accuracy. Use a miter saw or a hacksaw to cut the aluminum along the marked line. For shaping, you can use a file or a deburring tool to smooth out any rough edges. Additionally, if you need to bend the aluminum, a sheet metal brake or a vise can be used. Always wear appropriate safety gear, such as gloves and safety glasses, when working with aluminum profiles.

- Q: Is it possible to utilize aluminum profiles in the construction or structure of commercial buildings and factories?

- <p>Yes, aluminum profiles are commonly used in commercial buildings and factories due to their strength, durability, and lightweight properties. They are ideal for constructing frameworks, window and door frames, and support structures. The corrosion resistance of aluminum also makes it suitable for industrial environments where exposure to harsh chemicals or weather conditions is a concern. Additionally, aluminum profiles are easy to maintain and can be recycled, contributing to the sustainability of construction projects.</p>

- Q: Can aluminum profiles be used for modular office partitions?

- Yes, aluminum profiles can be used for modular office partitions. Aluminum profiles are lightweight, durable, and versatile, making them an ideal choice for constructing modular office partitions. They can be easily assembled and disassembled, allowing for flexibility and reconfiguration as per the office layout requirements. Additionally, aluminum profiles offer a sleek and modern aesthetic, making them a popular choice for office spaces.

- Q: What are the different types of hinges used with aluminum profiles?

- There are several types of hinges commonly used with aluminum profiles, including butt hinges, piano hinges, continuous hinges, pivot hinges, and concealed hinges. Each type of hinge offers different features and advantages, allowing for various installation options and movement capabilities when working with aluminum profiles.

- Q: Can aluminum profiles be used in electrical panel manufacturing?

- Indeed, electrical panel manufacturing can incorporate aluminum profiles. Aluminum, renowned for its lightweight and enduring nature, boasts remarkable electrical conductivity, rendering it apt for electrical panel applications. Moreover, its proficiency in heat dissipation proves vital in averting system overheating. Aluminum profiles can be effortlessly shaped and tailored to adhere to the unique prerequisites of electrical panel designs. In addition, aluminum's resistance to corrosion guarantees the durability of the electrical panel. Overall, owing to their myriad advantages, aluminum profiles remain a favored option in electrical panel manufacturing.

- Q: What are the different packaging options for aluminum profiles?

- Aluminum profiles can be packaged in various ways to suit the specific needs and preferences of customers. Here are some common packaging options: 1. Bundling: Small profiles of the same length and shape can be bundled together using straps or bands. This option allows for easy handling and transportation. 2. Wooden crates: Larger or delicate profiles are often packed in wooden crates, which provide excellent protection during shipping. The crates can be customized to fit the profiles perfectly. 3. Cardboard tubes: Thin and lightweight profiles, such as those used in the packaging industry, can be packaged in cost-effective cardboard tubes. This option ensures lightweight transportation and storage with adequate protection. 4. Pallets: When dealing with a large volume of profiles, pallets are commonly used. The profiles are stacked and secured on the pallet using strapping or shrink wrap. Pallets allow for efficient handling using forklifts or pallet jacks. 5. Custom packaging: Customers with specific requirements can opt for custom packaging solutions. This may include foam inserts, plastic wraps, or personalized labeling. Custom packaging ensures proper protection and adherence to handling instructions. To summarize, the packaging options for aluminum profiles depend on factors such as size, fragility, and volume. Whether it's bundling, wooden crates, cardboard tubes, pallets, or custom packaging, each option offers its own benefits in terms of protection, handling, and transportation convenience.

- Q: This question asks for the various types of adhesives that can be used for bonding aluminum profiles to building structures.

- <p>There are several types of adhesives used to attach aluminum profiles to building structures, including epoxy adhesives, which offer high strength and resistance to chemicals and temperature changes; polyurethane adhesives, known for their flexibility and durability; acrylic adhesives, which provide good adhesion on a variety of surfaces and are resistant to UV light; and silicone adhesives, which are excellent for sealing and bonding in environments with fluctuating temperatures. Each adhesive type has specific properties that make it suitable for different applications and environmental conditions in construction.</p>

- Q: Can aluminum profiles be used for exhibition stands?

- Yes, aluminum profiles can be used for exhibition stands. Aluminum profiles are lightweight and versatile, making them an ideal choice for exhibition stands. They can be easily assembled and disassembled, allowing for easy transportation and storage. Additionally, aluminum profiles can be customized to fit the specific design and layout requirements of an exhibition stand. They can be used to create frames, partitions, and display panels, providing a sturdy and professional-looking structure. The use of aluminum profiles in exhibition stands also offers the flexibility to add accessories such as lighting fixtures, shelving, and signage, further enhancing the overall visual appeal and functionality of the stand.

- Q: Features of aluminum profiles

- Thermal conductivityThe thermal conductivity of aluminum alloy is about 50-60% of copper, which is beneficial to the manufacture of heat exchangers, evaporators, heating appliances, cooking utensils, and the cylinder head and radiator of automobiles.FerromagnetismAluminum is non ferromagnetic, which is an important feature of the electrical and electronic industries. Aluminum can not be spontaneous combustion, which is involved in loading and unloading or exposure to flammable and explosive materials is important.

- Q: What are the load-bearing capacities of different aluminum profile shapes?

- The load-bearing capacities of various aluminum profile shapes differ depending on several factors, including the specific aluminum alloy used, the profile's size and dimensions, and its intended application. Aluminum profiles, also referred to as extrusions, are available in a wide range of shapes, which include I-beams, T-beams, square tubes, rectangular tubes, angles, and channels. Each shape possesses a distinct load-bearing capacity due to its structural design and cross-sectional properties. For instance, I-beams exhibit a high load-bearing capacity due to their shape, enabling efficient distribution of weight along the flanges. These profiles are commonly employed in structural applications that require supporting heavy loads. T-beams, on the other hand, possess a load-bearing capacity akin to I-beams but feature a different cross-sectional shape. They find utility in applications necessitating a flat surface on one side, such as in the construction or automotive industries. Square and rectangular tubes are versatile profiles widely used in building structures, frames, and support systems. Their load-bearing capacity is contingent upon the tube's wall thickness and size. Angles and channels, characterized by their L-shaped and U-shaped cross-sections respectively, are commonly employed in the construction and manufacturing sectors. The load-bearing capacity of these profiles is influenced by their size and dimensions. It is important to note that manufacturers typically provide the load-bearing capacities of aluminum profiles, which should be consulted for specific applications. Moreover, engineering calculations and considerations, such as deflection, bending moments, and safety factors, should be taken into account when determining the appropriate aluminum profile shape and size for a given load-bearing requirement.

Send your message to us

High Quality Aluminum H Extrusion Profiles for Kitchenware

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords