High Quality Aluminum Extrusion Profiles C Channel with a Good Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

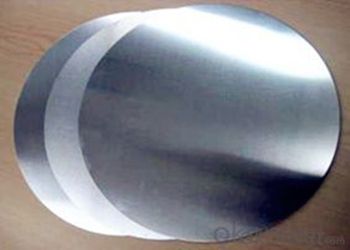

Aluminum Circles

Product introduction

Aluminum Circles are widely used in electronics, cosmetic, medicine, culture and education and auto parts. Electrical appliances, heat preservation, machinery manufacturing, automotive, aerospace,military, mold,construction,printing and other industries. Such as kitchen utensils such as non-stick pan,pressure cookers and other hardware supplies such as shades,water heaters shell,is the largest amount of aluminum alloy strip deep processing of one of the products.

Production methods

Punch processing

1. rough material cut (cut into a square) 2. Blank (punching into the Aluminum discs you want)

If it is a roll material, it is necessary to open the material.

Aluminum Circles Picture

Alloy state

Main series: 1 series, 3 series, 5 series, 6 series, 8 series is in the majority.

State : O, H ;

Introduction of our company

Our company is a professional Aluminium Coil Suppliers and Aluminum Circles manufacturers,mainly supply Aluminium Coil,Aluminum Circles,Aluminium discs,Aluminum Sheet,1100 Aluminum Sheet,1050 Aluminum Sheet,1060 Aluminum Sheet, Household Aluminum Foil,Aluminum Foil for Pharmaceutical Packaging,Aluminum Foil Tape,Aluminum Foil for Air Conditioner,Aluminum Foil for Container ,Aluminum Circles for Kitchenware,Aluminum Disc for Cookware,Aluminium Circle Sheet etc. series of aluminum products, sincerely welcome everyone to visit.

- Q: Are there any specific regulations or standards for using aluminum profiles in certain industries?

- Yes, there are specific regulations and standards for using aluminum profiles in certain industries. Aluminum profiles are widely used in various industries such as construction, transportation, aerospace, and manufacturing. These industries have specific requirements and standards that must be met to ensure the safety, performance, and quality of the products or structures that incorporate aluminum profiles. In the construction industry, for example, the use of aluminum profiles in windows, doors, curtain walls, and building facades must comply with building codes and regulations. These codes specify the required strength, fire resistance, energy efficiency, and structural integrity of the aluminum profiles used in these applications. In the transportation industry, aluminum profiles are commonly used in the manufacturing of vehicles, including cars, trucks, trains, and airplanes. There are regulations and standards set by organizations such as the Department of Transportation (DOT) and the Federal Aviation Administration (FAA) that govern the use of aluminum profiles in these applications. These regulations ensure that the aluminum profiles used in transportation are strong, lightweight, and meet safety requirements. The aerospace industry also has specific regulations and standards for aluminum profiles used in aircraft manufacturing. Aluminum profiles used in aircraft must meet stringent requirements for strength, durability, corrosion resistance, and fire resistance. Organizations like the FAA and the European Union Aviation Safety Agency (EASA) establish guidelines and standards to ensure the safe and reliable use of aluminum profiles in the aerospace industry. Manufacturing industries also have their own set of regulations and standards for using aluminum profiles in various applications. These standards often relate to the quality and dimensional tolerances of the aluminum profiles, as well as any specific requirements for their use in manufacturing processes or equipment. Overall, the use of aluminum profiles in certain industries is subject to specific regulations and standards to ensure compliance with safety, performance, and quality requirements. These regulations help to ensure that aluminum profiles are used in a manner that is safe, reliable, and meets the specific needs of the industry in which they are employed.

- Q: Are aluminum profiles compatible with glass or other glazing materials?

- Glass and other glazing materials can be used with aluminum profiles. Aluminum is a popular choice for window and door frames because it is strong, durable, and versatile. Combining aluminum with glass allows for the creation of stylish and functional windows, doors, and architectural elements. Aluminum profiles are specifically designed to securely hold and support glass panels, ensuring a safe and stable glazing system. Furthermore, aluminum profiles can also be used with polycarbonate or acrylic sheets, giving flexibility in design and construction. In summary, aluminum profiles are highly compatible with glass and various glazing materials, making them a dependable option for contemporary architectural projects.

- Q: What are the safety regulations concerning the use of aluminum profiles in construction?

- <p>Yes, there are safety regulations related to the use of aluminum profiles in construction. These regulations vary by country and region but generally include requirements for material strength, durability, and resistance to environmental factors. Standards such as ASTM B221 for aluminum and aluminum alloy extruded bars, rods, and profiles, and ISO 6361 for aluminum and aluminum alloy extruded profiles, provide guidelines on dimensions, tolerances, and mechanical properties. Compliance with local building codes and regulations is crucial, which may include fire resistance, load-bearing capacity, and corrosion resistance. Additionally, proper installation practices and adherence to manufacturer's specifications are essential to ensure safety and structural integrity.</p>

- Q: This question asks for an overview of the various types of fasteners that can be used in conjunction with aluminum profiles.

- <p>Aluminum profiles are commonly used in construction and manufacturing, and they require fasteners for assembly. The different types of fasteners include: 1. T-nuts and T-bolts: These are used for creating strong connections within the profile. 2. Clamping blocks: These are used to secure profiles together without the need for drilling. 3. Corner brackets: These are used to create 90-degree connections between profiles. 4. Angle brackets: Similar to corner brackets but for creating angled connections. 5. End caps: These are used to cover the ends of profiles for a finished look. 6. Dowels: These are used for aligning and joining profiles together. 7. Screws and bolts: These are used for securing components to the profiles. Each type of fastener serves a specific purpose and is chosen based on the particular application and design requirements.</p>

- Q: What is the difference between aluminum profile and sheet metal?

- Aluminum extrusions can be produced by extrusion or casting. In contrast, the aluminum sheet is flat, mainly for all types of surface.

- Q: Can aluminum profiles be used in signage and display applications?

- Yes, aluminum profiles can definitely be used in signage and display applications. Aluminum is a lightweight and versatile material that offers many benefits for these purposes. It is durable, corrosion-resistant, and can withstand various weather conditions, making it suitable for both indoor and outdoor applications. Aluminum profiles can be easily customized in terms of shape, size, and finish, allowing for the creation of unique and eye-catching signs and displays. Additionally, aluminum profiles can be easily assembled and disassembled, making them convenient for transportation and installation. Overall, aluminum profiles provide a great solution for signage and display applications due to their durability, versatility, and aesthetic appeal.

- Q: This question asks for methods to prevent rust formation on aluminum profiles during the periods of storage and transportation.

- <p>To prevent rust on aluminum profiles during storage and transportation, follow these guidelines: 1. Keep aluminum profiles dry and clean, avoiding contact with moisture or corrosive substances. 2. Store profiles in a cool, dry place, away from direct sunlight and heat sources. 3. Use protective packaging materials to shield profiles from physical damage and moisture. 4. Apply a protective coating or sealant to the aluminum surface if it's exposed to harsh environments. 5. Regularly inspect stored profiles for signs of corrosion and address any issues promptly. By adhering to these practices, you can minimize the risk of rust formation on aluminum profiles during storage and transportation.</p>

- Q: What are the regulations and standards that govern the use of aluminum profiles in construction?

- <p>Yes, there are several regulations and standards related to the use of aluminum profiles in construction. These include international standards such as ISO 7039 for anodized aluminum and ISO 9001 for quality management systems. Additionally, regional standards like the European EN 755 for extruded aluminum alloys and the American Architectural Manufacturers Association (AAMA) standards for aluminum products in buildings are crucial. Compliance with these standards ensures the safety, durability, and performance of aluminum profiles in construction applications.</p>

- Q: How many tons of aluminum can be produced by a ton of aluminium ingots?

- There are many factors to consider in this problem, and in the case of insufficient conditions, we can only compare them by using the hypothesis method. But personally think that a meal of aluminum ingots can definitely make a full or more than a ton of aluminum. The product is Aluminum Alloy, pure aluminum processed into Aluminum Alloy, so the process is sure to add other metal components (such as silicon, iron, copper, manganese, magnesium, zinc, chromium, titanium), assuming that the pure aluminum ingots is one hundred percent, so in the process of loss amount the amount of aluminum must be smaller than the metal, so the results will come out

- Q: The company must tender, but it needs material certification, but what do not know exactly?

- Enterprise legal person business license, China Quality Association approved, the national industrial product production permit, 9001 certificate, a copy of tax registration certificate. Surely that will be enough

Send your message to us

High Quality Aluminum Extrusion Profiles C Channel with a Good Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords