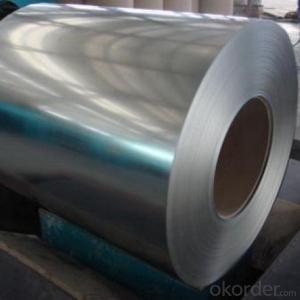

4 Feet By 8 Feet High Quality Aluminum Coil/Sheet Manufactured in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1 Specifications of High quality Aluminum Coil/Sheet

| Original Price | USD2370 |

| Current Price | USD2280 |

| Alloy | AA1050, AA1060, AA1070, AA1100 |

| Temper: | H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

| Thickness: | 2m- 3m |

| Width: | 30mm-2000mm |

| Standard: | GB/T17748-1999, ASTM, ISO, EU standard |

| Special Specification is available on customer’s requirement | |

2 Usage/Applications of High quality Aluminum Coil/Sheet

Aluminum Coil is widely used for electronics, instruments, lighting decoration, packing industry, and house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel, aluminum composite pipe etc.

3 Packaging & Delivery of High quality Aluminum Coil/Sheet

Packaging:Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers. Pallet weight: Max. 2.30 tons.

Shipment:the goods will be delivered in 30 days after getting the buyer's payment.

4 Production Flow of High quality Aluminum Coil/Sheet

Melting-Rolling- Cutting- Annealing--Packing

- Q: This question asks for methods to preserve the aesthetic quality of aluminum sheets and prevent deterioration over time.

- <p>To maintain the appearance of aluminum sheets over time, follow these steps: 1. Regularly clean the sheets with a mild detergent and water to remove dirt and grime. 2. Avoid using harsh chemicals or abrasive materials that can scratch the surface. 3. Apply a protective coating or sealant if the sheets are exposed to harsh weather conditions or corrosive environments. 4. Inspect the sheets periodically for signs of corrosion or damage and address any issues promptly. 5. Keep the aluminum sheets dry, as moisture can lead to rust and other forms of deterioration. Proper maintenance will help preserve the appearance and longevity of aluminum sheets.</p>

- Q: What are the applications of aluminum sheets?

- Aluminum sheets have a wide range of applications due to their unique properties and versatility. Some common applications of aluminum sheets include: 1. Construction: Aluminum sheets are used in the construction industry for various purposes such as roofing, siding, gutters, and facades. They offer excellent durability, corrosion resistance, and the ability to withstand extreme weather conditions. 2. Transportation: Aluminum sheets are extensively used in the transportation industry, particularly in the manufacturing of automobiles, airplanes, trains, and ships. Their lightweight nature helps reduce fuel consumption and enhance vehicle performance while maintaining strength and durability. 3. Packaging: Aluminum sheets are widely used for packaging purposes, especially in the food and beverage industry. They are used for making cans, foils, and containers due to their ability to protect the contents from light, moisture, air, and bacteria. 4. Electronics: Aluminum sheets are used in the production of electronic devices, such as laptops, smartphones, and tablets. They are often used for heat dissipation due to their excellent thermal conductivity properties, ensuring the longevity and performance of electronic components. 5. Industrial applications: Aluminum sheets find applications in various industrial sectors, including aerospace, marine, chemical, and energy. They are used for manufacturing heat exchangers, tanks, pipes, and other equipment, thanks to their corrosion resistance and high strength-to-weight ratio. 6. Decorative purposes: Aluminum sheets are also utilized for decorative purposes in architecture and interior design. They can be easily shaped, colored, and textured to create attractive facades, wall panels, ceilings, and furniture. 7. Reflective surfaces: Aluminum sheets are commonly used for their reflective properties. They are used in mirrors, solar panels, light fixtures, and reflective signage to enhance brightness and improve energy efficiency. In summary, aluminum sheets are widely used in multiple industries due to their exceptional properties. Their lightweight, durability, corrosion resistance, and thermal conductivity make them a preferred choice for construction, transportation, packaging, electronics, industrial applications, decoration, and reflective surfaces.

- Q: What are the different alloy compositions available for aluminum sheets?

- Aluminum sheets offer a variety of alloy compositions, each with its own distinct properties and applications. There are several common alloy compositions to consider. Firstly, we have 1100, which stands out for its exceptional corrosion resistance and high thermal conductivity. This alloy finds its place in chemical equipment, heat exchangers, and food processing equipment. Next, 3003 presents good formability, moderate strength, and excellent corrosion resistance. It is commonly employed in packaging, tanks, and architectural applications. Moving on to 5052, this alloy boasts high strength and good formability. It is often utilized in marine applications, as well as in aircraft and automotive parts. For those seeking excellent strength, good formability, and high corrosion resistance, 6061 is the alloy of choice. It is commonly found in structural applications like bridges, buildings, and transportation equipment. Lastly, we have 7075, known for its remarkably high strength and good machinability. Aerospace applications, as well as high-stress parts in the automotive and sporting goods industries, benefit from this alloy. These examples merely scratch the surface of the numerous alloy compositions available for aluminum sheets. The selection of the appropriate alloy hinges on specific application requirements, such as strength, corrosion resistance, formability, and machinability.

- Q: Can aluminum sheets be textured for grip?

- Indeed, grip can be achieved through texturing aluminum sheets. Numerous techniques exist to impart texture onto aluminum sheets, including embossing, etching, and the application of a non-slip coating. By undergoing these processes, patterns, grooves, or raised bumps can be added to the sheet's surface, heightening its grip and rendering it suitable for situations where slip resistance holds significance. The textured surface amplifies the friction between the sheet and any object it comes into contact with, thereby delivering a secure grip, even in damp or slippery circumstances.

- Q: How is the coated aluminum mirror plate produced?

- Coated aluminum mirror as mean coated aluminum, aluminum mirror above the mirror effect is produced by the mirror, the mirror is in ordinary composite aluminum plate, the aluminum mirror cost will be relatively low. But the film of aluminum in the actual use of the process, must consider the problems of high temperature, because the mirror can not afford high temperature, easy to fall off, of course, as the most low-end series aluminum mirror inside a material, or he has a huge market range.And protect the protective coating of the material, whether it is coated with aluminum, or polished mirror aluminum, or other oxidation mirror aluminum, there will be.Interested in more understanding, you can search for "Ming Bao metal.""

- Q: How do aluminum sheets perform in terms of magnetism or electromagnetic interference?

- Aluminum sheets have a very low magnetic permeability, which means they are not attracted to magnets and do not retain a magnetic field. This property makes aluminum sheets highly resistant to magnetism and reduces their susceptibility to electromagnetic interference (EMI). Aluminum is often used in applications where shielding against EMI is necessary, such as in electronic devices, aerospace structures, and electrical enclosures. Due to its non-magnetic nature, aluminum sheets do not interfere with magnetic fields or create any significant electromagnetic fields of their own. This makes them ideal for applications that require minimal magnetic distortion, such as in MRI machines or sensitive scientific instruments. In addition to their low magnetism, aluminum sheets also have good electrical conductivity. This property allows them to effectively dissipate any induced currents or static charges, further reducing the risk of electromagnetic interference. Overall, aluminum sheets perform excellently in terms of magnetism and electromagnetic interference. Their low magnetic permeability, non-magnetic nature, and good electrical conductivity make them a favorable choice for applications where EMI shielding and minimal magnetic distortion are essential.

- Q: Hi, I'm new here. Yoroshigu.I'm trying to make flash paper for magic tricks.To do that I have to make flash powder but in my location I can hardly find ingredients. Not to think about buying. Usually, I wait for a season and buy firecrackers. Then, I take the power and soak them into the paper and dry. This works but not so flash. Burned more likely.So, I wonder if I take aluminium oxide from aluminium oxide sandpaper and mix with powder from firecracker would produce a brighter flash than firecracker power alone?anyone know please share.

- You should set this project aside. Ignore my advice? You're on track for a Darwin Award. You win!

- Q: Can aluminum sheets be bent or formed into different shapes?

- Yes, aluminum sheets can be bent or formed into different shapes. Aluminum is a highly malleable metal, which means it can be easily shaped or formed without breaking or cracking. This property makes it highly versatile for various industries and applications. Aluminum sheets can be bent, rolled, or pressed to create different shapes or forms, such as cylinders, cones, or complex geometric structures. The ability to bend or form aluminum sheets opens up a wide range of possibilities for manufacturing, construction, automotive, aerospace, and many other industries.

- Q: Are the aluminum sheets suitable for manufacturing kitchen backsplashes?

- Yes, aluminum sheets are suitable for manufacturing kitchen backsplashes. Aluminum is a lightweight and durable material that is resistant to corrosion and heat. It is also easy to clean and maintain, making it ideal for use in kitchens where splatters and spills are common. Aluminum sheets can be easily cut and shaped to fit any kitchen size and design, allowing for flexibility in creating a customized backsplash. Additionally, aluminum offers a sleek and modern aesthetic, adding a contemporary touch to the kitchen décor. Overall, aluminum sheets are a practical and stylish choice for manufacturing kitchen backsplashes.

- Q: (given the fact that specific gravity of aluminum is 2.7)1. What is its volume?2. The ingot is suspended from a rope and totally immersed in water. What is the tension in the rope (the apparent weight of the ingot in water)?

- first find the volume of your aluminium. youll need this when analyzing the bouant force F(b). the sg of aluminum is 2.7 and the density of water is 1000 kg/m^3 so the density of aluminum is 2.7x1000=2700kg/m^3. the mass is 71N/g = 7.237512742 kg. so volume of our piece of aluminum = mass/density = 0.0026805603 m^3 now analyze the forces being applied to the system. There are three, the force of gravity F(g), the buoyant force F(b) and the tension T. Tension and buoyant force push up, gravity pulls down. the system will be at rest since the rope is holding it at rest. so T + F(b) - F(g) = 0 T + (Volume aluminum X density water X g) - (MAss of aluminum x g) = 0 T + (0.0026805603x1000x9.81) - (71 N (given in problem)) = 0 Solving for T, T = 44.70370346 N = 45 N using sig figs.

Send your message to us

4 Feet By 8 Feet High Quality Aluminum Coil/Sheet Manufactured in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords