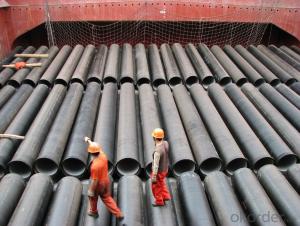

Ductile Iron Pipes with high performance good price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

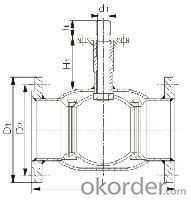

full welded forged steel ball valve

Design Features of full welded forged steel ball valve

The body of ball valve is full welded,selects high quality forged material,and adopts the advanced forged forming technology to form two semi-spheres which are welded into a whole in the middle of the body.This welding technology differentiates the ball valve form others,and makes the valve more spherically,so the valve structure is more compacter,lighter and stronger.Besides,the middle direct welding realize highly accurate valve body manufacturing,makes fully and completely sealing between the seat and ball.The full welding instead of bolts completely avoids the outside leakage,so ball valve is the ideal product for under-ground,offshore working platform and under-sea equipments.

Adopting fixed plates or trunnion to support the ball

The top and bottom of the ball is supported by upper and lower fixed plates or stem and trunnion,and the ball is accurately placed in the center of the ball valve to achieve complete seals and precise movements.When plate adopted,the force exerted by the medium to the ball is distributed via the plate to the left and right bodies,so that the stem does not bear the blending moment from the medium,but only the torque from the ball rotation during the opening/closing of the valve.The low-friction PTFE Teflon composite bearings installed between the ball axis and fixed plate and between the stem and the trunnion can absorb ball moving action caused by the pressure of the medium.This structure brings stable actions and easy operations for the ball valves,and the required operation torque can be reduced,so smaller actuators can be used,and the cost is cut down.

ball valve seat is floating structure,means the seat can move along the medium direction,so that the seat can fit against the ball all the time.

(Ⅰ)Double piston effect structure seat of full welded forged steel ball valve

Seat design is special double pistons effect structure,it can ensure the seal wherever the medium flows into the ball valve.

(Ⅱ)Seat multistage seal strucute of full welded forged steel ball valve

As following graphic instruction,on seat bearing ring,set two soft sealing rings(A and B)and metal sealing spherical surface which can seal with the ball.Seat ring A is spring loaded,which seals the surface with the ball tightly to the surface to form an initial seat;When there is pressure generated from medium,the piston force is generated to make seal ring A elastically deformed and seal ring B fit the surface of the ball surface due to the piston effect caused by area difference,thus the second seal forms.When the medium pressure is rising.It will generate huge pressure to seal ring A and seal ring B,so the two seals have a greater elastic deformation,then metal seal ball surface compact with ball surface to form the third level of metal to metal seal.

(Ⅲ)Secondary seat seal device of full welded forged steel ball valve

As the above graphic instruction,the secondary seal device(seat grease injection valve)can be chosen according to the actual working condition,medium requirement,seal requirement,etc.Seat ring grease injection valve is a one-way valve,installed on the body,which can prevent the leakage and inject grease under the outside force.When secondary seal is required,there is a grease injecting channel and hole on the seat ring.The grease can form a seal between the seat and the ball,and then stop the leakage.

Standards Applied of full welded forged steel ball valve:

Design Standard | API 6D customize |

Connection Standard | ASME B 16.25-2007 ASME B 16.5 ASME B 31.4 ASME B 31.8 DIN GB、GB/T JB、JB/T JIS customize |

Test Standard | API 6D customize |

Face to Face | API 6D customize |

Pressure-teperature rating | ASME B 16.34-2004 customize |

Marking | MSS SP-25 customize |

FAQ of full welded forged steel ball valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: How does ductile iron pipe perform in high-temperature environments?

- Due to its unique properties and characteristics, ductile iron pipe performs exceptionally well in high-temperature environments. It is known for its high strength, toughness, and durability, making it suitable for various applications that involve elevated temperatures. One of the main advantages of ductile iron pipe in high-temperature environments is its ability to withstand thermal expansion and contraction. With a low coefficient of thermal expansion, the material can handle significant temperature fluctuations without suffering detrimental effects. This ensures that the pipe remains structurally stable, avoiding deformation or cracking when exposed to high temperatures. Moreover, ductile iron pipe exhibits excellent thermal conductivity, allowing it to efficiently transfer heat. This prevents the accumulation of excessive heat and reduces the risk of thermal stress. Additionally, its high thermal conductivity enables it to dissipate heat quickly, ensuring that the pipe remains within safe operating temperatures. Furthermore, ductile iron pipe has a high melting point of approximately 2200°F (1200°C). This characteristic guarantees that the pipe maintains its structural integrity even in extremely high-temperature environments, making it capable of effectively handling hot fluids, steam, and other substances at elevated temperatures without compromising performance. Another crucial aspect is the corrosion resistance of ductile iron pipe. It is commonly coated with protective linings, such as cement mortar or epoxy, which act as a barrier against corrosion caused by high temperatures. These linings prevent direct contact between the pipe and corrosive substances, thereby ensuring the pipe's longevity in high-temperature environments. In conclusion, ductile iron pipe is an excellent choice for high-temperature environments due to its exceptional strength, thermal stability, thermal conductivity, and corrosion resistance. Its ability to withstand thermal expansion, high melting point, and efficient heat transfer properties make it a reliable and durable option for various applications in such conditions.

- Q: Can ductile iron pipe be used for sewer and wastewater systems?

- Yes, ductile iron pipe can be used for sewer and wastewater systems. Ductile iron is a strong and durable material that can withstand the harsh conditions of sewage and wastewater transport. It has excellent corrosion resistance and can handle high-pressure environments, making it a suitable choice for these applications.

- Q: Can ductile iron pipes be used for underground storage of hazardous materials?

- No, ductile iron pipes should not be used for underground storage of hazardous materials. Ductile iron pipes are commonly used for water and sewage systems due to their durability and corrosion resistance. However, they are not designed to withstand the specific requirements and potential hazards associated with storing hazardous materials underground. When it comes to underground storage of hazardous materials, it is crucial to use materials that are specifically engineered to handle the chemical properties and potential risks associated with these substances. Specialized materials such as high-density polyethylene (HDPE) or fiberglass reinforced plastic (FRP) are commonly used for underground storage tanks due to their excellent chemical resistance and ability to maintain structural integrity over time. Using ductile iron pipes for such purposes may lead to corrosion, leaks, or even catastrophic failures, resulting in environmental contamination and potential harm to surrounding areas. Therefore, it is essential to consult with experts and adhere to applicable regulations and guidelines when selecting materials for underground storage of hazardous materials to ensure safety and prevent potential hazards.

- Q: What are the different methods for testing ductile iron pipe?

- There are several methods available for testing ductile iron pipe to ensure its quality and reliability. These methods include: 1. Hydrostatic Testing: This is the most common method used for testing ductile iron pipe. It involves filling the pipe with water and pressurizing it to a specified level. The pipe is then inspected for any leaks or deformations under the applied pressure. Hydrostatic testing helps determine the pipe's ability to withstand internal pressure without failure. 2. Tensile Testing: This method involves subjecting a sample of the ductile iron pipe to a gradually increasing tensile load until it fractures. The test measures the ultimate tensile strength, yield strength, and elongation of the material. Tensile testing helps evaluate the pipe's mechanical properties and its ability to withstand tension without breaking. 3. Hardness Testing: This method measures the hardness of the ductile iron pipe using various techniques such as Brinell, Rockwell, or Vickers hardness tests. Hardness testing provides information about the material's resistance to deformation, wear, and fatigue. It helps assess the pipe's durability and resistance to external forces. 4. Impact Testing: This method involves striking a notched sample of the ductile iron pipe with a pendulum or falling weight to measure its impact resistance. The test determines the material's ability to absorb energy during sudden loading or impact. Impact testing helps evaluate the pipe's ability to withstand accidental impacts or dynamic loads. 5. Ultrasonic Testing: This non-destructive testing method uses high-frequency sound waves to detect internal defects or discontinuities in the ductile iron pipe. Ultrasonic testing can identify voids, cracks, or inclusions that may affect the pipe's structural integrity. It helps ensure the pipe's soundness and reliability. 6. Magnetic Particle Testing: This method is primarily used for detecting surface or near-surface defects in the ductile iron pipe. It involves applying a magnetic field to the pipe and then applying magnetic particles to the surface. Any defects present will cause the magnetic particles to gather and form visible indications. Magnetic particle testing helps identify surface cracks, laps, or other defects that may affect the pipe's performance. These different testing methods help ensure that ductile iron pipe meets industry standards and specifications, ensuring its quality and reliability in various applications.

- Q: Can ductile iron pipe be used for irrigation pumping stations?

- Yes, ductile iron pipe can be used for irrigation pumping stations. Ductile iron pipe is known for its durability, corrosion resistance, and ability to withstand high pressure and flow rates. It is a commonly used material for water supply systems, including irrigation pumping stations, due to its reliability and long service life.

- Q: How much is a ductile iron pipe dn400?

- Ductile iron pipe nominal diameter is 80 ~ 2200 mm, compared with grey cast iron, high strength, good toughness, thin wall metal, less dosage, and can withstand high pressure, effective length of 5 meters, 6 meters and 8 meters; according to the different thickness of P, G two. It is the development direction of cast iron pipe.

- Q: How long is the service life of the cast iron pipe, and the time of use of ductile iron pipes?

- Ductile iron is a new type of pipe, as long as we use it properly, the quality of its products, then the use of ductile iron pipes for 20-35 years, basically no problem. But whether it is ductile cast iron pipe, or some other things, the use of more years, and more or less, there will be some problems, ductile iron pipe can not escape the robbery. However, as long as we use the ductile iron pipe in the process of careful care, the service life of the problem is not to worry about.

- Q: Can ductile iron pipe be used for oil and gas pipelines?

- Ductile iron pipe is indeed capable of being utilized for oil and gas pipelines. Renowned for its robustness, durability, and ability to resist corrosion, ductile iron pipe is well-suited for various applications, including the transportation of oil and gas. This pipe has been widely employed in the industry for many years and has consistently proven to be a dependable option for pipeline systems. Furthermore, ductile iron pipe is capable of withstanding high pressure and heavy loads, thus meeting the demands of oil and gas pipelines. However, it is crucial to ensure that the specific grade and specifications of the ductile iron pipe align with the requirements of the particular oil and gas project to guarantee optimal performance and longevity.

- Q: Is the crankshaft material forged or ductile iron?

- Cast iron can not be forged, only steel, malleable iron can not be forged, only the crankshaft is particularly hot, can not meet the strength of the hardening when forging

- Q: How does ductile iron pipe perform in extreme weather conditions?

- Ductile iron pipes are renowned for their exceptional performance in adverse weather conditions. These pipes demonstrate remarkable durability, resistance, and flexibility, making them suitable for enduring harsh weather such as extreme temperatures, heavy rainfall, snowfall, and even earthquakes. One of the notable characteristics of ductile iron is its capacity to withstand damage caused by freezing temperatures. Unlike other materials, ductile iron pipes possess a low coefficient of thermal expansion, enabling them to resist the expansion and contraction that occurs during freeze-thaw cycles without experiencing cracks or breaks. Consequently, these pipes remain intact and continue to function optimally even in extremely cold conditions. Furthermore, ductile iron pipes exhibit excellent resistance to corrosion, rendering them highly resilient to the corrosive effects of severe weather. They are shielded by a sturdy zinc coating, which acts as a barrier against rust and other forms of corrosion. This coating, in conjunction with the inherent strength of ductile iron, grants these pipes exceptional resistance to the corrosive effects of rain, snow, and moisture. Moreover, ductile iron pipes possess superior flexibility, allowing them to accommodate ground movement and seismic activity. In areas prone to earthquakes or soil shifting, these pipes can absorb stress and strain without fracturing, guaranteeing a continuous supply of water and sewage services even in the most challenging weather conditions. Overall, ductile iron pipes excel in extreme weather conditions due to their durability, resistance to freezing, corrosion, and flexibility. Their ability to withstand the elements ensures an uninterrupted supply of water and sewage systems, providing reliability and peace of mind to utility providers and communities, even in the most unforgiving environments.

Send your message to us

Ductile Iron Pipes with high performance good price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords