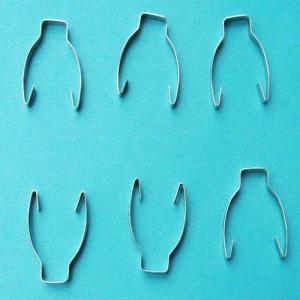

OEM Precision Customized Aluminum Metal Stamping Parts

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000pieces pc

- Supply Capability:

- 20000 Piece/Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details Of Metal Stamping

| Brand Name | MOULDSZ | Material | Stainless steel |

| Coating | Zinc plating | Size | Different size can do |

| MOQ | 5000pcs | Port | Shanghai |

Specifications Of Metal Stamping

| Material | Stainless steel, steels ,aluminum alloy, red copper, brass, bronze alloy, etc |

| Processing | Mold designing, stamping, stretching, deep drawing, bending, welding, plating, assembling and packaging. |

| Coating | nickel plating, zinc plating, chrome plating, gold plating, acid pickling, etc. |

| Production | Supply more than 10,000pcs per day with one mold |

Features Of Metal Stamping

1) With thickness from 0.1-0.4mm

2) High precision

3) Digital camera contact and cell phone contact

4) Mainly applied in battery contacts, locks, machinery, home appliances and electronic products

5) The products range is continuously being broadened

6) We make every endeavor to develop towards high precision and highly

sophisticated to satisfy customers' requirements

Application Of Metal Stamping

Electric meters, shunts, temperature controllers (thermostats), mutual inductors, current transformers, relays, transformers, sound ,car GPS ,Car chargers, etc

Packaging & Delivery Of Metal Stamping

1.Packaging:with the waterproof paper or do as your need .

2.Delivery : according to your order quantity .

- Q: What is the major of mold design and manufacturing?

- Study of mold design and manufacturing needs to learn the following courses: computer applications, CAD and mechanical drawing, mechanical design, electrical and electronic technology, stamping process and mold design, plastic molding process and mold design, mold manufacturing, mold machining technology, mould CAD /CAM, mold professional English courses.Sheet metal is a kind of hardware mold, but also a kind of mold; plastic knowledge, of course, is the most necessary to understand, because the design and manufacture of plastic mold is to put out the plastic parts

- Q: How about the employment prospects of mold design and manufacturing?

- According to reports, with the manufacturing city of Dongguan to build, enterprises demand more and more talented people mold, the existing mold design and CNC technology talent is far from meeting the needs of the manufacturing sector in Dongguan. Mold design, mold development, mold maintenance, CAM/CNC engineers, CNC programming, CNC machining has become one of the highest recruitment positions in the Dongguan talent market. In all kinds of recruitment, talent is also keen to mold enterprise marked "urgent", "recruiting" one of the few posts, so that the monthly salary of 6000 yuan to hire NC technicians, the annual salary of 160 thousand yuan to recruit skilled workers die "phenomenon.

- Q: I am a fresh undergraduate student. I have just learned how to deal with the die design. How about the treatment? Do you know what to say?

- I am sorry, I am Jiangsu, landlord, master, then good, that is, the beginning of work, wages will not be very high, this kind of professional value is experience, big companies mostly consider the elite, see your good fortune

- Q: What is the difference between mold design and mold manufacturing? Hard to learn?

- The design is to draw the shape of the mold on paper or computer, and use two-dimensional images to express the three-dimensional mold. Manufacturing is the process of drawing a mold on a paper or computer by a lathe. Better spatial imagination! And junior high school does not matter, a lot of things you want to make up, or it is easy to fill.

- Q: What basic knowledge do CNC milling machine software programming and mold design require? Where do you start learning?

- It is recommended to operate machine tools first, and then to study!

- Q: Learn die design, what information books to buy good?

- [[]] technology mechanical national standard mechanical drawing CAD.Rar AutoCAD2000 engineering drawing print skills.Pdf practical tutorial AutoCAD2000.Pdf cad-V17V18 Unigraphics.rar CAD in the bus in the mold production and application of.Pdf CAXA tutorial FLASH.rar CAXA entity design V2 training tutorial.Doc CAXA entity design V2 training tutorial.Rar CAXA Manufacturing Engineer (including XP training course the example file).Rar machining CAXA Manufacturing Engineer XP training tutorial case containing parts of.Rar CAXA Manufacturing Engineer solid modeling of generating surface cutter method.Pdf Cdrs.Pdf Cimatron Chinese tutorial example entry -.Rar MoldWizard.Rar MasterCAM surface peo-e-2001 surface design manual.Doc.Pdf PRO-E2001 simplified version Chinese tutorial.Pdf Pro-Engineer basic manual.Rar Pro-E parts based on the.Pdf design articles Pro-E part Design Basic.Pdf pro-nc three.Pdf Pro_ENGINEER milling machine parts processing. Design of.Rar ProE 2000i (under) the development and application of advanced features.Pdf ProE 2000 more columns (30 papers).Rar proe2.0 V1.1 e2.0relation-02.avi proe2.0 Chinese installation manual Chinese installation manual V1.1 e2.0relation-04.avi ProEngineer 2000i.Pdf ProEngineer Drawing industrial design tutorial tutorial.Rar PROE the parameters of a detailed description of.Doc ProE basic manual proebasic.rar proe processing...

- Q: The mould making and designing is more promising than the mechanical drawing (mechanical processing technician)

- Each one has his good points, you'll want to look at how to develop, if you want to work in the factory is of course design and production mold is good, if later want to study after a period of time to do their own boss or mold technician is better. But even the mold design and design can not be fifteen thousand, plus commission, the kind of basic no, even if there is only 1/10000, almost.

- Q: Stamping die design and manufacturing thinking and exercises, mold processing relative to the general parts of what features?

- After the completion of the mold manufacturing, it is necessary to adjust and test the mold. Only after forming the qualified parts, the mold manufacturing is qualified.

- Q: Am I allowed to skip the process and die as a mold designer? I have been working for a month and have a good knowledge of the machining process

- I suggest you should do the processing for a period of time, because the basis of die design or manufacture of all kinds of parts should be very familiar with, there is ambition is a good thing, but to lay a good foundation, can be done in the processing at the same time, more attention, how to design out needed to pursue the parts, you can also in my spare time in learning to say, maybe one day you'll find that you have no need to apprentice, and can be designed and manufactured!

- Q: Does material forming and processing involve mold design and manufacturing?

- This major includes welding, casting, forging, and moulds and so on

1. Manufacturer Overview

| Location | Suzhou, China |

| Year Established | 2004 |

| Annual Output Value | Above US$ 2.5 Million - US$ 5 Million |

| Main Markets | Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central, America, Northern Europe, Southern Europe, South Asia, Domestic Market |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | less than 50 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | about 500 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

OEM Precision Customized Aluminum Metal Stamping Parts

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000pieces pc

- Supply Capability:

- 20000 Piece/Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords